Preparation method for coal water slurry used for gasification

A technology of coal water slurry and coal slurry, which is applied in the field of clean coal, can solve the problem that coal slime is difficult to realize long-distance clean utilization, and achieve the effect of improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

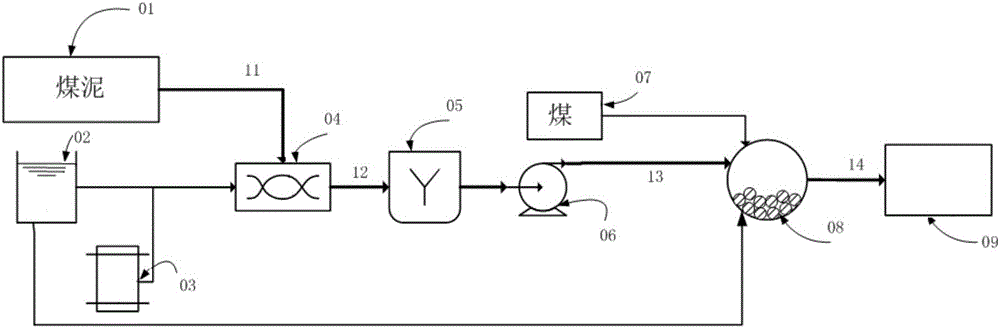

[0021] As mentioned in the background technology section, although most of the utilization methods of fine coal slime in the prior art are prepared into coal water slurry for clean utilization, they are basically on-site utilization or short-distance utilization of coal slime, and it is difficult to Realize long-distance transportation or storage of coal slime, and then realize long-distance clean utilization. In order to improve this defect in the prior art, in a typical implementation of the present application, a method for preparing coal slurry for gasification is provided. The preparation method includes: step S1, diluting the coal slurry with water to obtain Coal slurry; Step S2, adding coal and water to the coal slurry to mix to obtain a mixed coal slurry; Step S3, grinding the mixed coal slurry to obtain gasification water-based coal slurry.

[0022] In the above preparation method of the present application, the coal slime is diluted with water to prepare a coal slurr...

Embodiment 1

[0034] as attached figure 1As shown, the coal slime 01 from the coal washing plant with a water content of 26% and a particle size of 80% less than 0.5mm is sent to the agitator 04 through the belt 11, and is stirred together with the water in the water tank 02 and the additive 03 (lignin), and the average stirring The time is 15 minutes, and the concentration of the coal slurry after stirring is 50%.

[0035] The stirred coal slurry enters the storage tank 05 through the first delivery pipeline 12 . Then use the coal slurry pump 06 to send the coal slurry in the storage tank 05 into the wet rod mill 08 through the second delivery pipeline 13, and the length of the second delivery pipeline 13 is 2 km. The coal slurry transported into the rod mill 08 is ground together with the coal from the coal bunker 07 and the water in the water tank 02, and finally the coal water slurry with a concentration of 61% is sent into the coal water slurry gas through the third delivery pipeline ...

Embodiment 2

[0037] as attached figure 1 As shown, the coal slime 01 from the coal washing plant with a water content of 31% and a particle size of 95% less than 1mm is sent to the agitator 04 through the belt 11, and is stirred together with the water in the water tank 02. The average stirring time is 20 minutes, and the coal slurry concentration after stirring is 40%.

[0038] The stirred coal slurry enters the storage tank 05 through the first delivery pipeline 12 . Then use the coal slurry pump 06 to drive the coal slurry in the storage tank 05 into the wet rod mill 08 through the second delivery pipeline 13, and the length of the second delivery pipeline 13 is 500 km. The coal slurry sent into the rod mill 08 is ground together with the coal from the coal bunker 07 and the water in the water tank 02, and finally the coal water slurry with a concentration of 60% is sent to the gasifier 09.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com