Hosiery factory automatic warehouse capable of automatically storing and taking materials

An automated warehouse and automatic access technology, applied in the field of automated warehouses, can solve the problems of inability to meet production requirements, error-prone management processes, and low production efficiency, and achieve the effects of reducing manpower, saving floor space, and ensuring rational utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with the accompanying drawings.

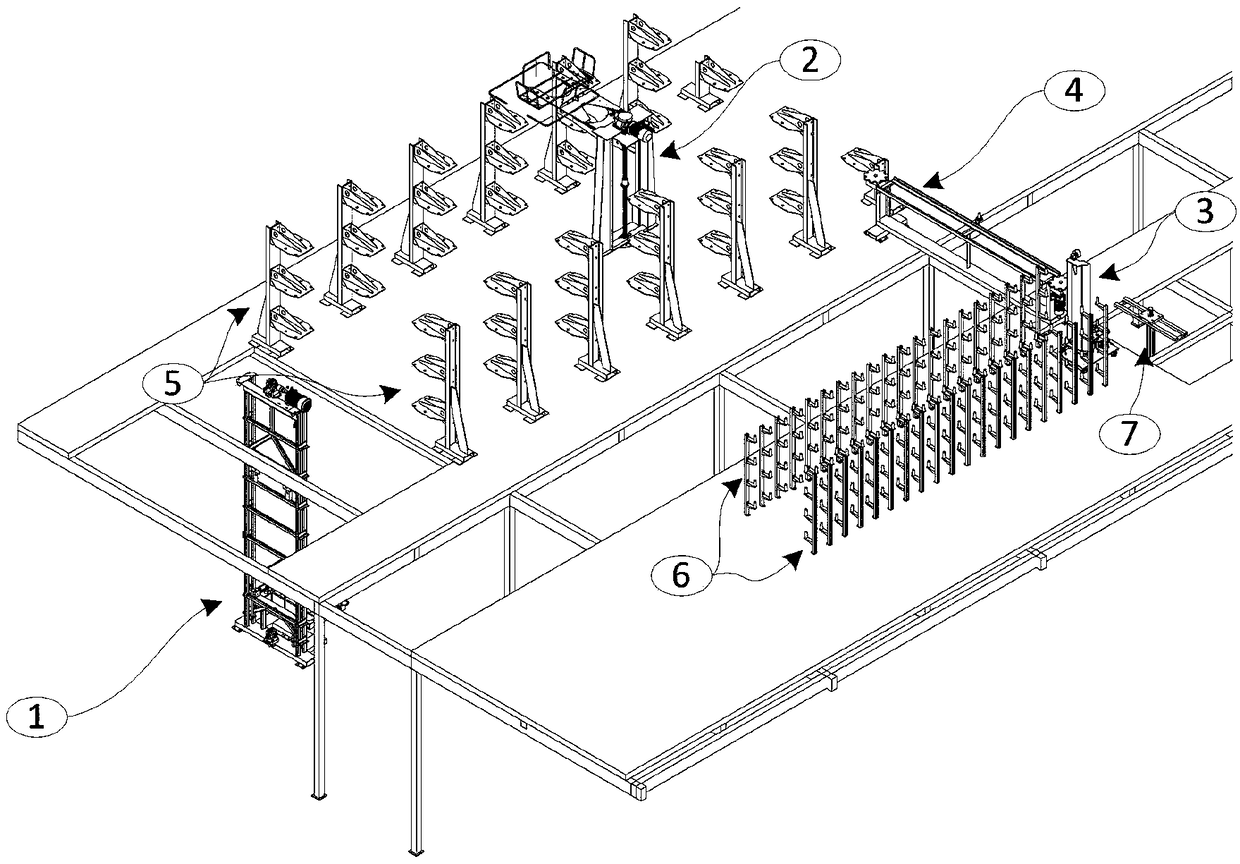

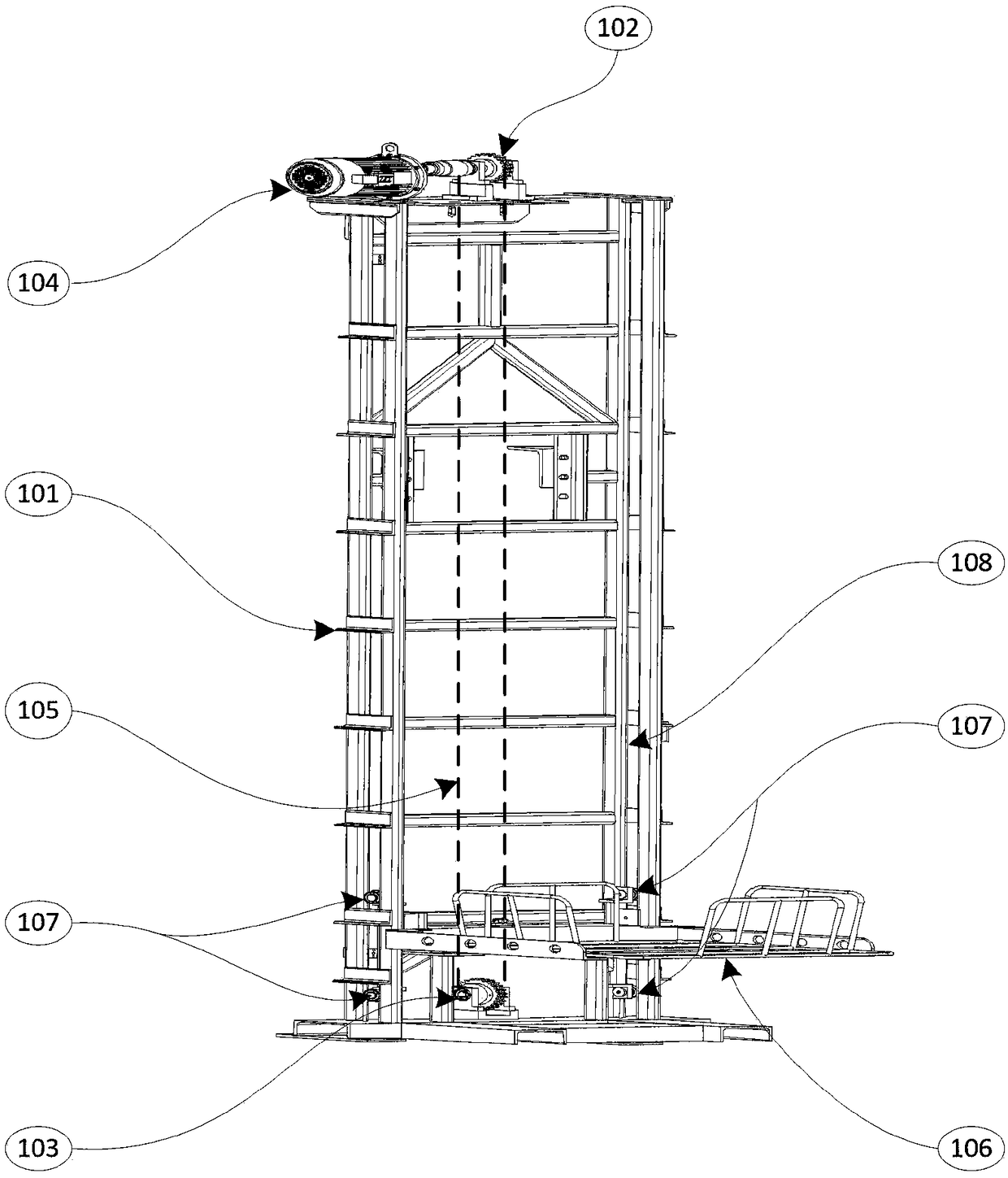

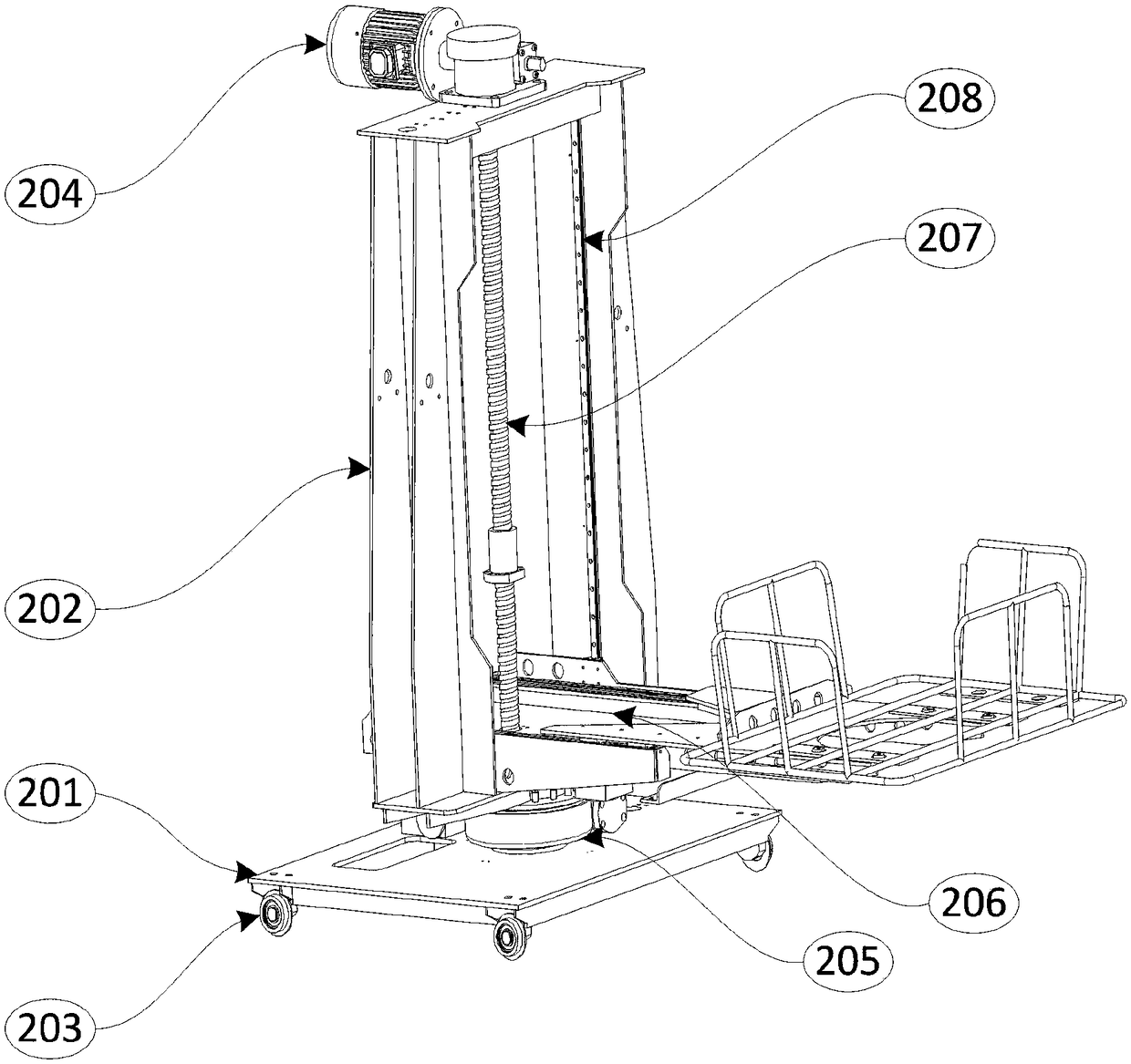

[0065] see figure 1 , Figure 5 to Figure 7 , an automatic warehouse for automatic storage and retrieval of materials in a hosiery factory, including a warehouse main body, the warehouse main body is erected above the hosiery machine area; the warehouse main body includes a hoist 1 and two storage areas for storing materials, respectively It is a large warehouse area and a small warehouse area with different storage capacity; the large warehouse area includes the large warehouse robot 2 and the large warehouse area storage rack 5, the large warehouse area storage rack 5 is located on both sides of the large warehouse robot 2, and the feeding end of the large warehouse area A hoist 1 is installed; the small warehouse area includes a small warehouse robot 3, a small warehouse area storage rack 6, and the small warehouse area storage rack 6 is located on both sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com