Biological alcohol oil and preparation method thereof

A bio-alcohol oil and ethanol technology, which is applied in the petroleum industry, liquid carbon-containing fuel, fuel, etc., can solve the problems of poor combustion-supporting performance and air pollution, and achieve the effects of protecting the environment, increasing the combustion value, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] The present invention also provides a preparation method of bioalcohol oil, comprising:

[0072] a) Provide mixed emulsifiers;

[0073] b) uniformly mixing the mixed emulsifier with methanol, water and ferrocene to obtain the bioalcohol oil composition.

[0074] Preferably, the emulsifier provided by the present invention is prepared by the inventor himself, so the preparation method of the emulsifier is specifically:

[0075] a1) Stir the ethyl acetate and ethanol uniformly for 5-10 minutes; obtain the first mixture;

[0076] a2) adding potassium hydroxide into the first mixture, and uniformly stirring for 5-10 minutes to obtain a second mixture;

[0077] a3) adding sodium hydroxide into the second mixture, stirring evenly for 10-30 minutes, to obtain the third mixture;

[0078] a4) standing the third mixture for 1-2 hours to obtain an emulsifier.

[0079] According to the present invention, the stirring speed in the preparation process of the emulsifier, that is, ...

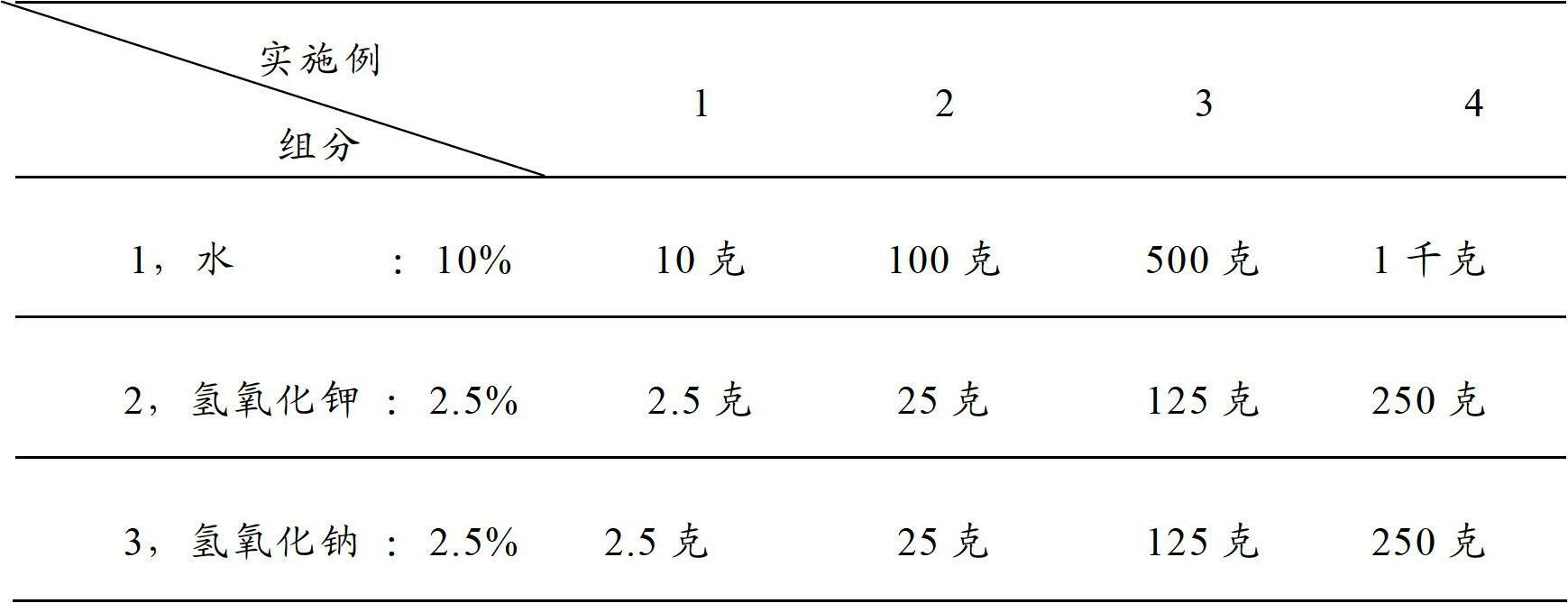

Embodiment 1

[0082] Mix ethyl acetate and absolute ethanol at a speed of 300r / min for 5min to obtain the first mixture, add potassium hydroxide to the first mixture, stir uniformly for 5min to obtain the second mixture, add sodium hydroxide to the In the second mixture, uniformly stirred for 20 minutes to obtain a third mixture, and the third mixture was left to stand for 2 hours to obtain an emulsifier.

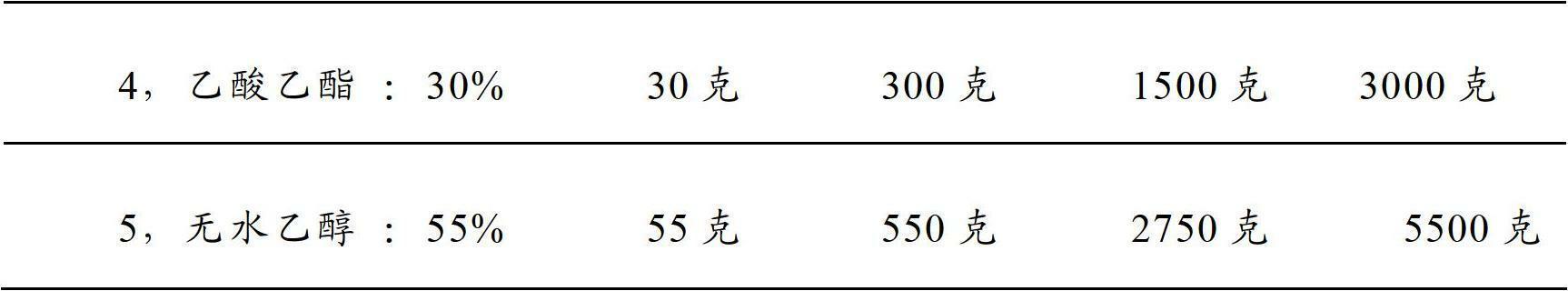

[0083] The methanol, the water, the emulsifier and the ferrocene catalytic combustion accelerant were uniformly mixed for 1 hour according to the parts by weight, and the stirring speed was 300 r / min to obtain the bioalcohol oil.

[0084] The addition amount of emulsifier and each component in the preparation of bioalcohol oil is shown in Table 1 and Table 2.

[0085] The bioalcohol oil prepared in the example was tested by the method provided in the GB16663-1996 alcohol-based liquid fuel standard, and the data results are shown in Table 3.

Embodiment 2~4

[0087] The content of each component is shown in Table 1 or Table 2, and the test results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com