Graphene-based nano iron oxide composite material and preparation method thereof

A technology of nanocomposite materials and alkenyl iron, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of reaction complexity, cumbersome preparation process, high cost of raw materials, etc., and achieve the goal of preparation process The effect of simplicity and safety, common and easy-to-obtain raw materials, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1 g of graphite oxide was added to 500 ml of deionized water, and the graphene oxide dispersion was obtained by ultrasonication for 1 hour, and at the same time, 3.5 g of ferric chloride hexahydrate solution was added to deionized water. Mix the above two solutions into a round bottom flask, stir for 30 minutes, gradually add ammonia water, and adjust the pH of the solution to 4. The gel was transferred to the bottom of the hydrothermal reaction tank and reacted at 150°C for 12 hours. The hydrothermal product is centrifugally washed several times with absolute ethanol and deionized water respectively, and after vacuum freeze-drying, the graphene-based iron oxide nanocomposite material is obtained.

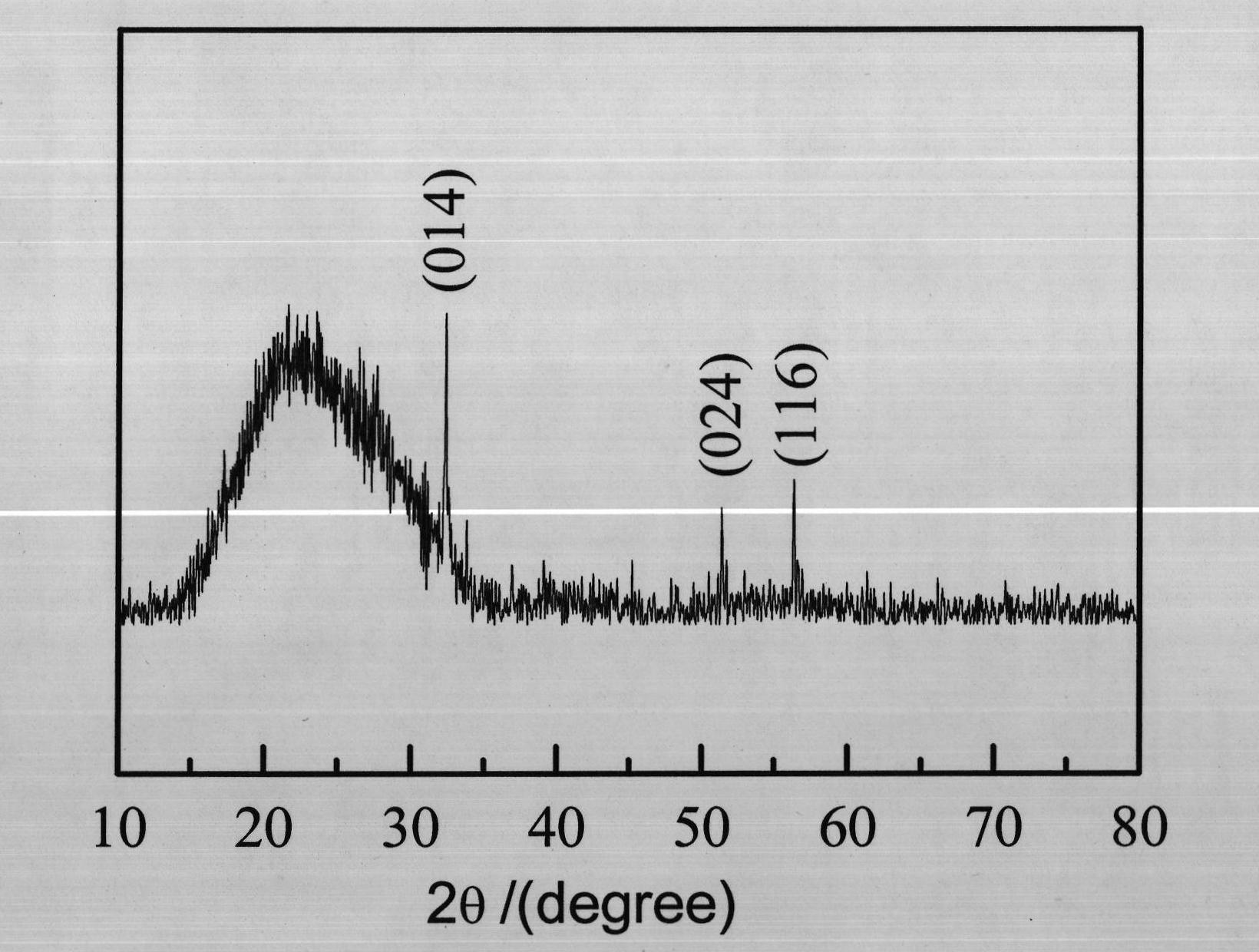

[0020] figure 1 It is the XRD pattern of the composite material obtained in Example 1 after annealing heat treatment. Depend on figure 1 It can be seen from the diffraction peaks that the composite mainly contains ferric oxide.

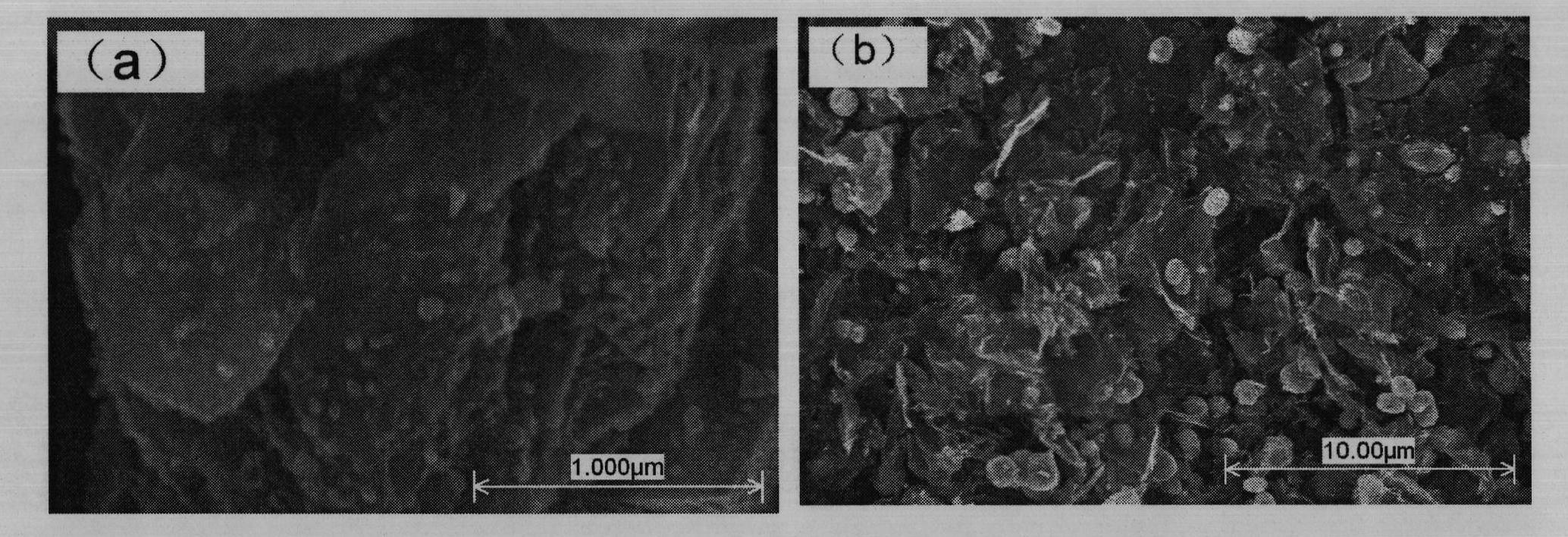

[0021] figure 2 a is the SEM image of t...

Embodiment 2

[0025] 1 g of graphite oxide was added to 500 ml of deionized water, and the graphene oxide dispersion was obtained by ultrasonication for 2 hours. At the same time, 10 g of ferric chloride hexahydrate solution was added to deionized water. Mix the above two solutions into a round bottom flask, stir for 30 minutes, gradually add sodium hydroxide solution, adjust the pH of the solution to 10, and fully precipitate the iron ions. The gel was transferred to the bottom of the hydrothermal reaction tank and reacted at 180°C for 20 hours. The hydrothermal product is filtered and washed several times with absolute ethanol and deionized water, and the graphene-based iron oxide nanocomposite material is obtained after vacuum freeze-drying.

[0026] figure 2 b is the SEM image of the composite material prepared in Example 2 after annealing heat treatment. It can be seen from the figure that iron oxide particles in the graphene-based iron oxide nanocomposite material obtained in Examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com