Design method of easily-removable support structure for SLM-manufactured metal parts

A support structure and design method technology, applied in the direction of improving process efficiency and energy efficiency, can solve problems affecting continuous processing, collapse of overhanging structures, etc., and achieve the effect of simple and practical method, low cost, and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

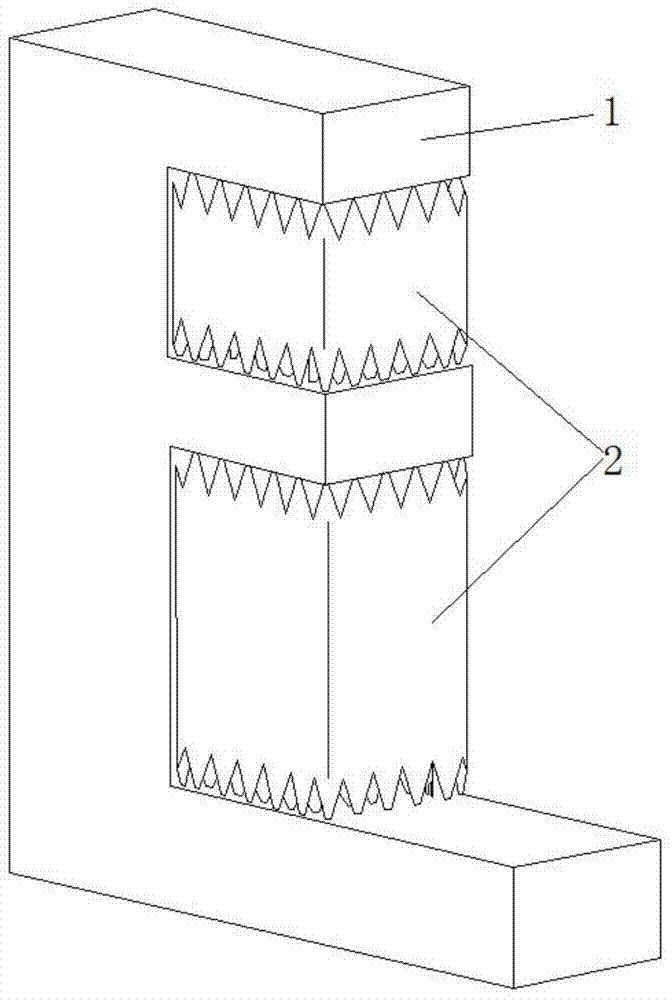

[0028] The structure diagram of this embodiment is as follows figure 1 , giving an example of such a overhanging surface. The main part entity 1 has two bosses, and the size reaches the order of tens of millimeters. In this order of magnitude, an auxiliary forming structure must be added to ensure the molding quality and dimensional accuracy of the bosses. Wait. Therefore, it is necessary to make necessary supports under the overhanging surface of the boss to ensure the shape. Part 2 in the figure is the supporting structure. After the SLM process is completed, the parts are taken out, and then such supports are removed to obtain the boss and overhanging surface structure.

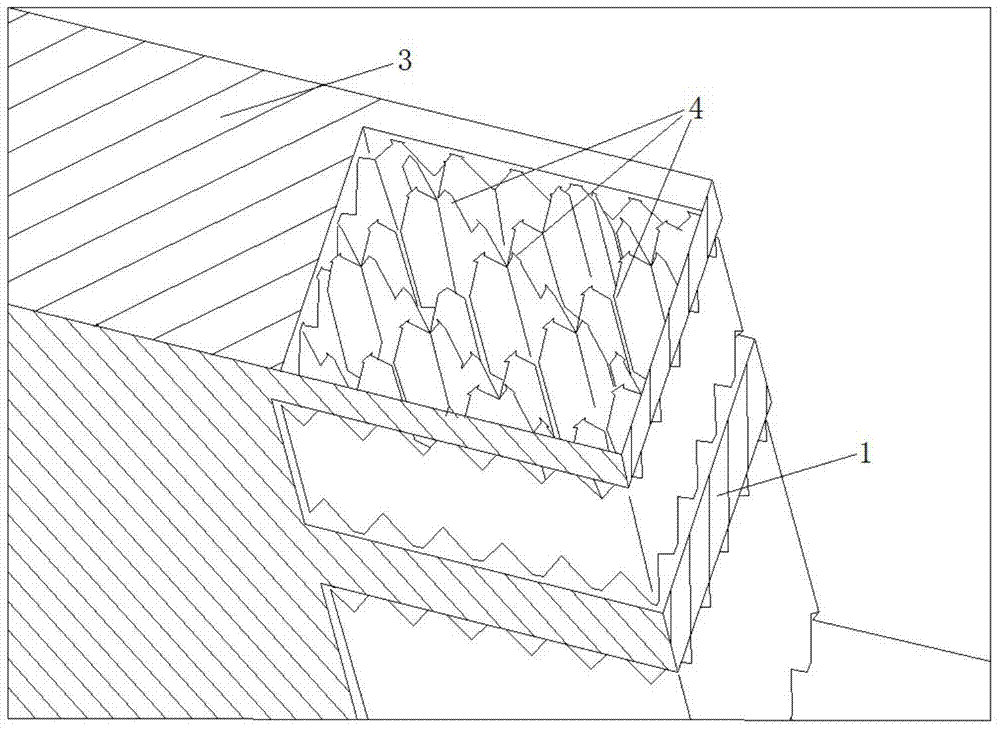

[0029] In order to increase the ease of removal of the support, the internal structure of the support is also designed, such as figure 2 As shown, 1 is the part entity, 3 is one ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com