Graphene band prepared with acid oxidized flat carbon nano-tube and method for preparing graphene band

A carbon nanotube and graphene technology, applied in the field of graphene strips and their preparation, can solve problems such as difficult directional cutting, lack of special defect sites, etc., and achieve the effects of simple method, easy realization and control, and narrow width.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

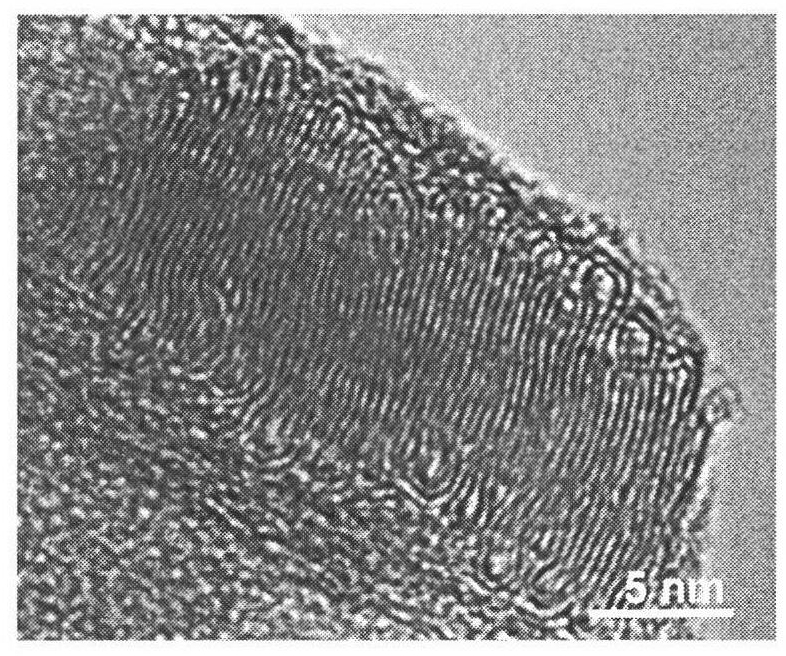

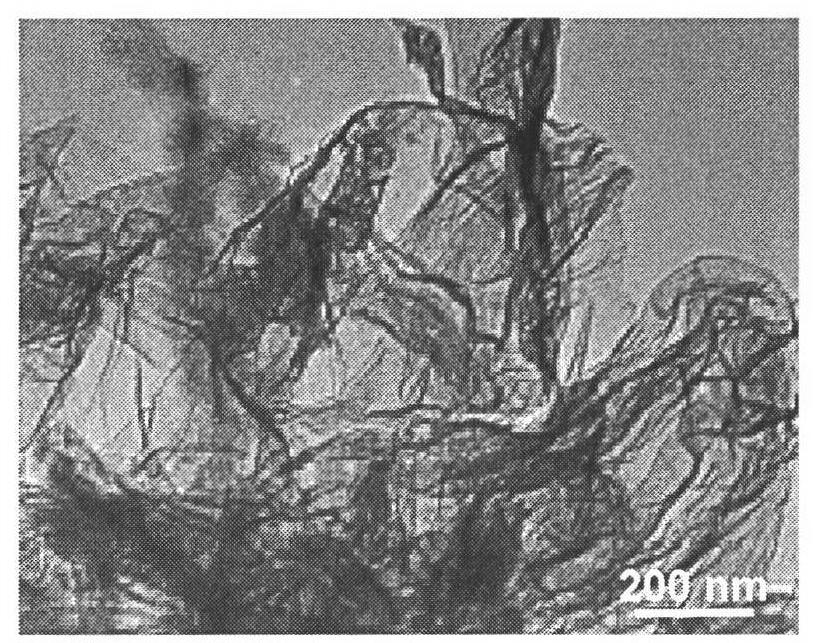

[0028] Example 1: Carbon nanotube fibers are prepared according to the method reported in patent CN101665997A, and the flat carbon nanotube fibers are formed by connecting and arranging flat carbon nanotubes. The flat carbon nanotubes prepared by the above-mentioned patented method are used as raw materials, and the microstructure is a stack of flat carbon nanotubes, as shown in the attached figure 1 . Using concentrated sulfuric acid as a pre-oxidant and potassium permanganate as an oxidant, carbon tube flat carbon nanotubes were cut by acid oxidation to prepare graphene strips. The oxidation conditions are as follows: the mass ratio of concentrated sulfuric acid to flat carbon nanotubes is 6, and the mass ratio of potassium permanganate to flat carbon nanotubes is 4. Add flat carbon nanotubes into concentrated sulfuric acid (98%), 60 ° C water bath, 200 rpm magnetic stirring for 30 minutes; add potassium permanganate, keep stirring at 60 ° C for 90 minutes for oxidation; ad...

Embodiment 2

[0030] Embodiment 2: experimental process is the same as embodiment 1, changes the mass ratio of concentrated sulfuric acid and oxidant potassium permanganate and carbon tube, the mass ratio of concentrated sulfuric acid and flat carbon nanotube is 3, the mass ratio of potassium permanganate and flat carbon nanotube The mass ratio is 2 to prepare graphene strips.

Embodiment 3

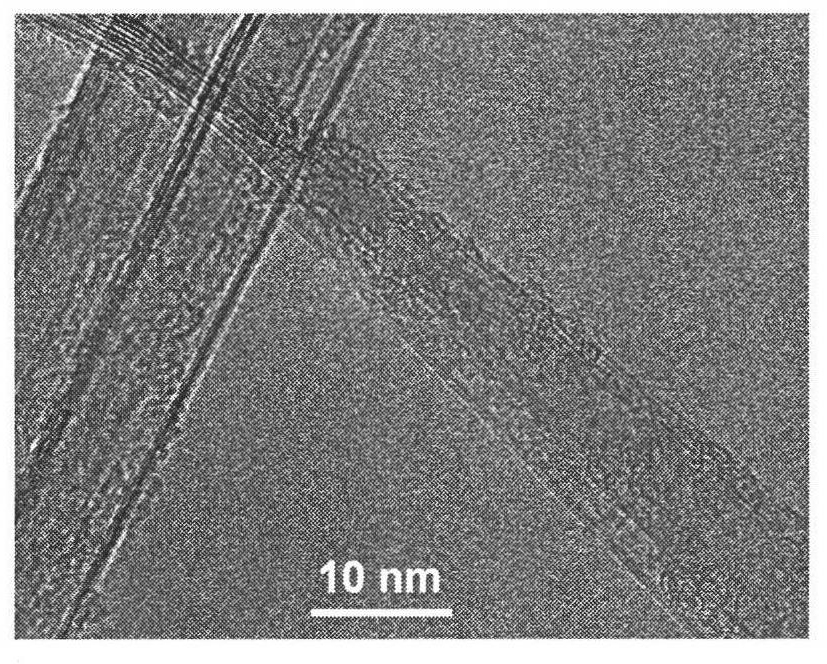

[0031] Embodiment 3: experimental process is the same as embodiment 1, changes the mass ratio of concentrated sulfuric acid and oxidizer potassium permanganate and carbon tube, the mass ratio of concentrated sulfuric acid and flat carbon nanotube is 7.5, the mass ratio of potassium permanganate and flat carbon nanotube Mass ratio is 5, makes graphene strip, as attached Figure 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com