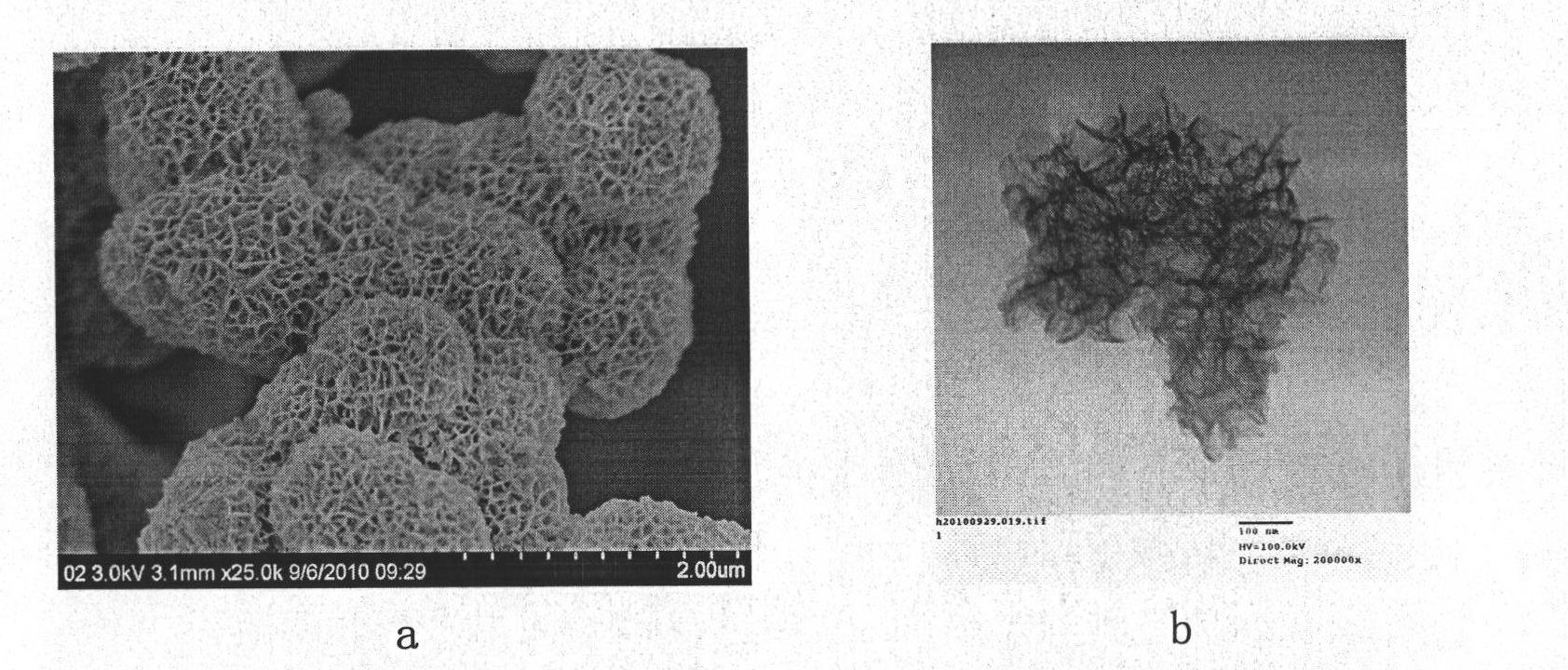

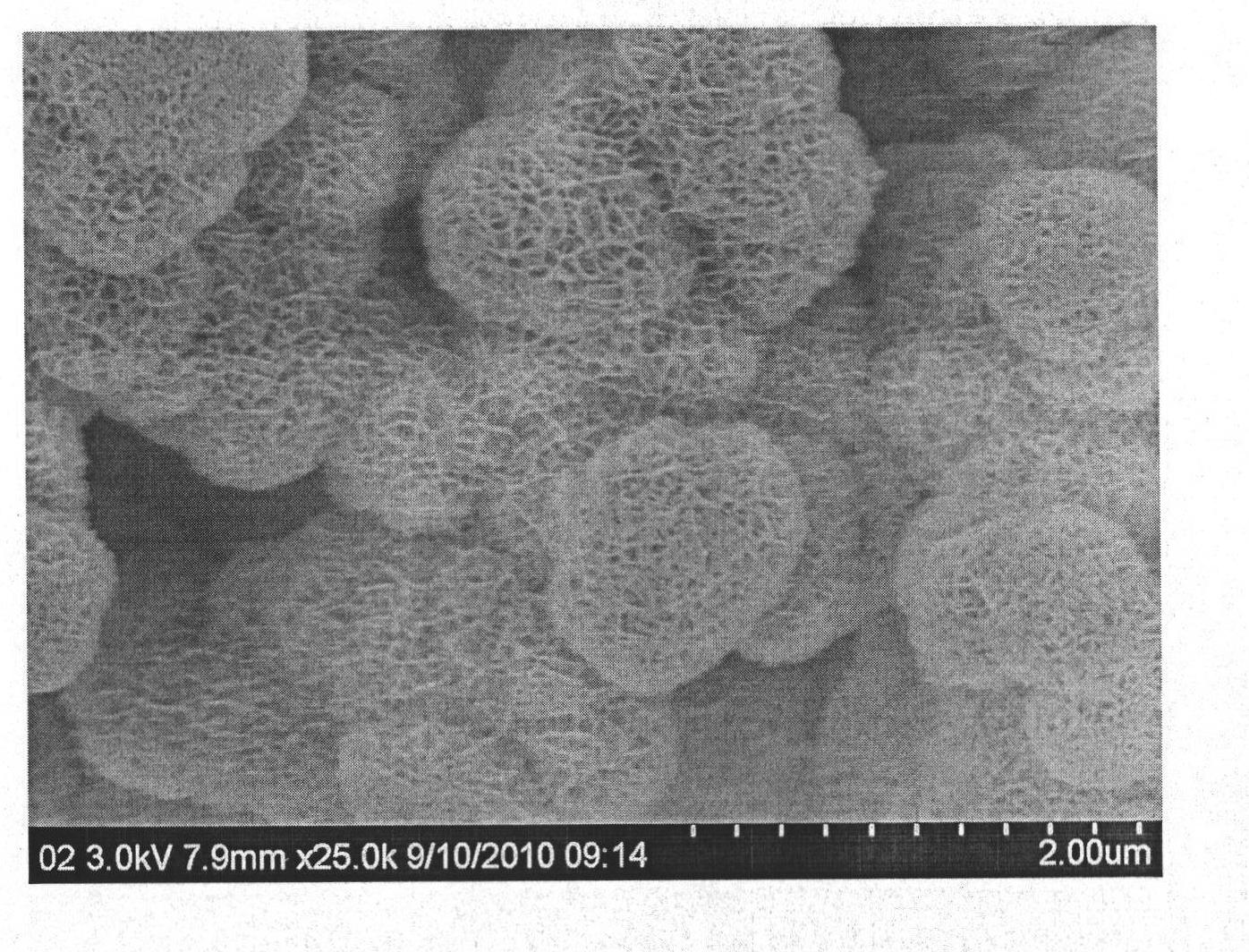

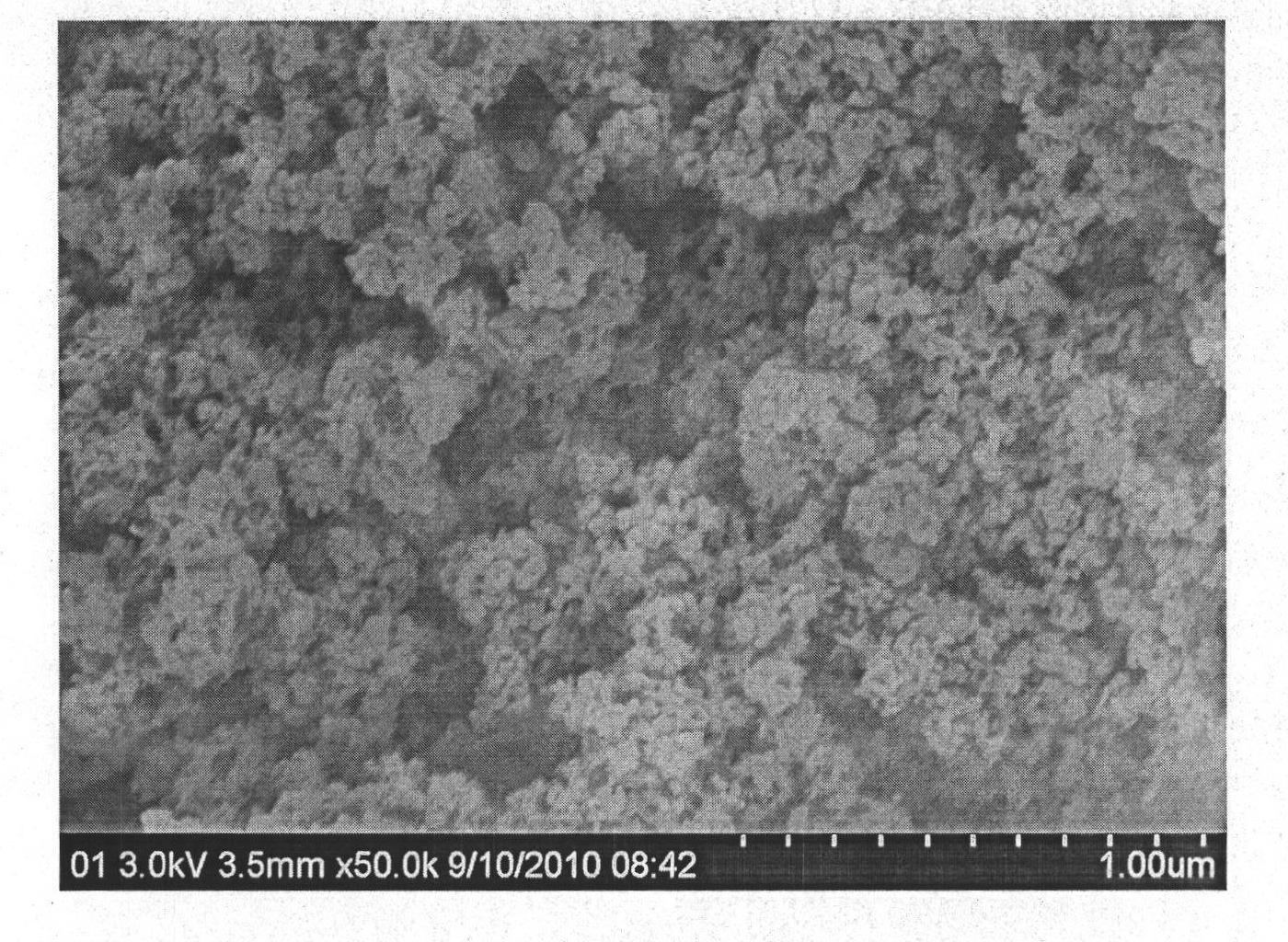

Preparation method of brain-coral-shaped birnessite type manganese dioxide

A technology of birnessite and manganese dioxide, which is applied in the field of nano-material preparation, can solve the problems of high requirements for experimental equipment, high production costs, and difficulties in sample post-processing, and achieve the effects of low cost, convenient processing, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Prepare 0.05mol / L KMnO 4 solution and an equal volume of 0.075mol / L MnSO 4 solution, and with H 2 SO 4 Adjust the pH value of both to 1, and then in KMnO 4 The solution is added to the KOH solution, and the amount of the substance added to the KOH is KMnO 4 2 times the amount of the substance (this amount of KOH can just be combined with the H generated during the reaction + completely neutralized), and then at room temperature, under the conditions of magnetic stirring, the KMnO obtained above 4 The solution was slowly added dropwise to the MnSO 4 In the solution, keep the pH value of the reaction system at 1 during the dropping process, KMnO 4 After the solution was added dropwise, it was stirred for another 15 min to obtain a dark brown solid precipitate, which was then centrifuged and washed with distilled water several times to remove possible remaining impurities in the target product. Finally, the obtained product was obtained at 110 ℃ drying overnight, th...

Embodiment 2

[0030] Prepare 0.05mol / L KMnO 4 solution and an equal volume of 0.075mol / L MnSO 4 solution, then to MnSO 4 solution and KMnO 4 A certain amount of H was added to the solution 2 SO 4 , so that the pH of the solution is 0, then in KMnO4 NaOH solution is added to the solution, and the amount of substance added with NaOH is KMnO 4 2 times the amount of the substance (this amount of NaOH can just completely neutralize the H+ generated in the reaction process), and then at room temperature and under the condition of magnetic stirring, the KMnO obtained above 4 The solution was slowly added dropwise to the MnSO 4 In the solution, keep the pH value of the reaction system at 0 during the dropping process, KMnO 4 After the solution was added dropwise, it was stirred for another 15 min to obtain a dark brown solid precipitate, which was then centrifuged and washed with distilled water several times to remove possible remaining impurities in the target product. Finally, the obtained...

Embodiment 3

[0032] Prepare 0.005mol / L KMnO 4 solution and an equal volume of 0.0075mol / L MnSO 4 solution, and with H 2 SO 4 Adjust the pH value of both to 2, and then in KMnO 4 A certain volume of KOH solution is added to the solution, and the amount of KOH added is KMnO 4 2 times the amount of the substance (this amount of KOH can just be combined with the H generated during the reaction + completely neutralized), and then at room temperature, under the conditions of magnetic stirring, the KMnO obtained above 4 The solution was slowly added dropwise to the MnSO 4 In the solution, keep the pH value of the reaction system at 2 during the dropping process, KMnO 4 After the solution was added dropwise, it was stirred for another 15 min to obtain a dark brown solid precipitate, which was then centrifuged and washed with distilled water several times to remove possible remaining impurities in the target product. Finally, the obtained product was obtained at 110 ℃ drying overnight, the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com