Graphene loaded Cu-CuxO composite material and preparation method thereof

A technology of composite materials and graphene, which is applied in nanotechnology for materials and surface science, electrode manufacturing, electrical components, etc., can solve problems such as research work that has not been reported in the literature, and achieve excellent comprehensive performance, strong binding force, The effect of good crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1.2 g of graphite oxide was added to 500 ml of deionized water, and the graphene oxide dispersion was obtained by ultrasonication for 4 hours. At the same time, 4.05 g of copper sulfate pentahydrate was dissolved in deionized water. The above two solutions were mixed evenly and put into a round bottom flask, stirred for 30 minutes, and sodium hydroxide solution was gradually added to adjust the pH of the solution to 9. The gel was transferred to a hydrothermal reaction kettle and reacted at 120°C for 12 hours. The hydrothermal product was washed several times by centrifugation with absolute ethanol and deionized water, and then vacuum freeze-dried. The obtained material was fired at 500°C under a nitrogen protective atmosphere for 2 hours, and cooled to room temperature to obtain graphene-supported Cu-Cu x O composite materials.

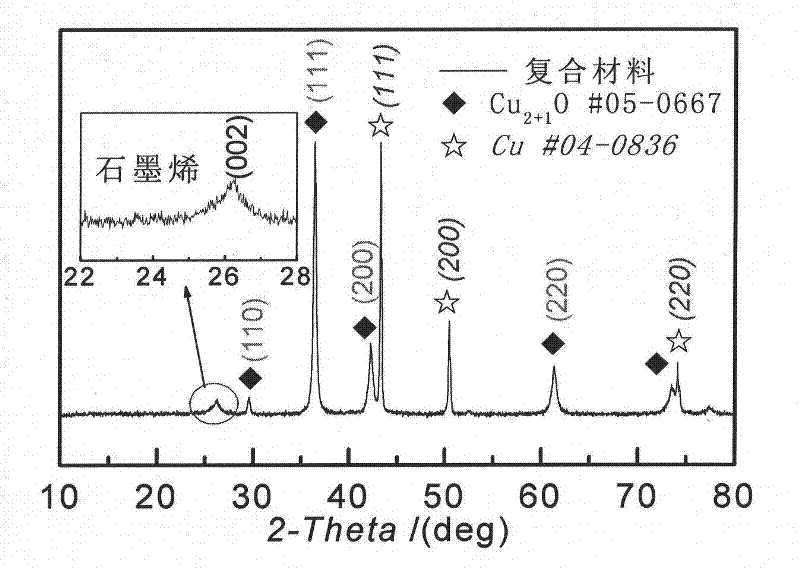

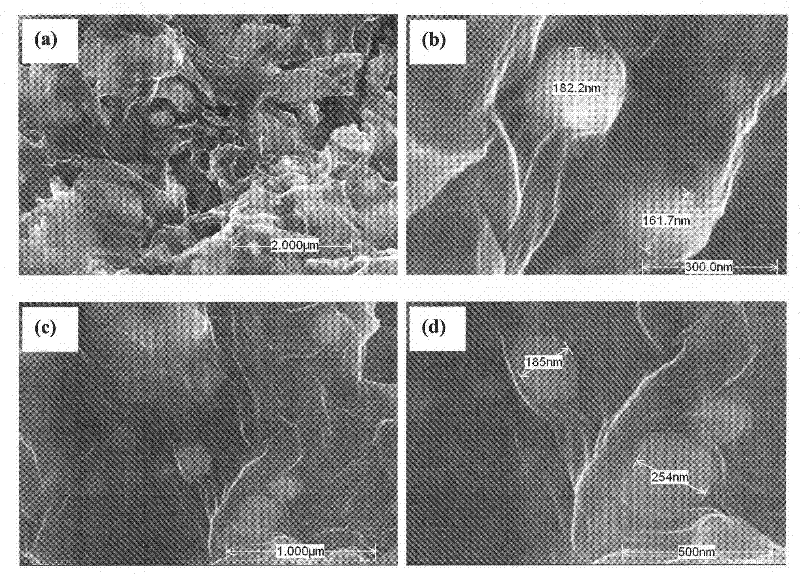

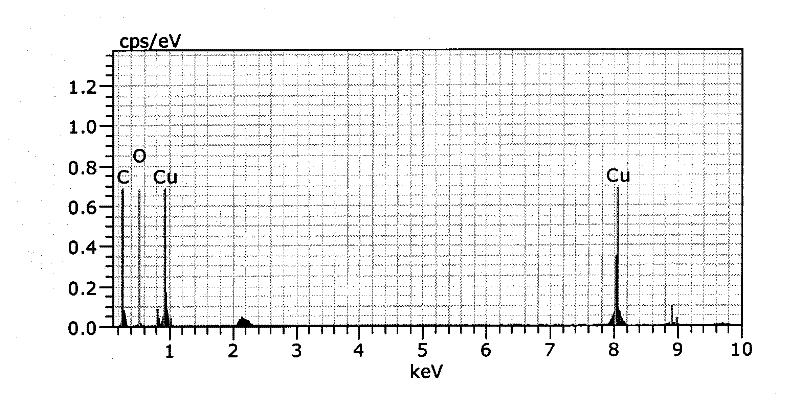

[0021] figure 1 It is the graphene loaded Cu-Cu prepared by embodiment 1 x XRD patterns of O composites. Depend on figure 1 The diffrac...

Embodiment 2

[0027] 1.2 g of graphite oxide was added into 500 ml of deionized water, and ultrasonicated for 2 hours to obtain a graphene oxide dispersion, and at the same time, 2.7 g of copper sulfate pentahydrate was dissolved in deionized water. Mix the above two solutions into a round bottom flask, stir for 30 minutes, gradually add dilute ammonia water, adjust the pH of the solution to 10, and fully precipitate the copper ions. The gel was transferred to the bottom of the hydrothermal reaction tank and reacted at 180°C for 20 hours. The hydrothermal product was filtered and washed several times with absolute ethanol and deionized water, and the graphene-loaded copper oxide composite material was obtained after vacuum freeze-drying. Then the obtained material was burned at 500°C under an argon protective atmosphere for 2 hours, and cooled to room temperature to obtain graphene-supported Cu-Cu x O composite materials.

[0028] figure 2(c) and (d) are SEM images of the composite mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reversible capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com