Silicon and carbon composite material for lithium ion battery anode and preparation method thereof

A silicon-carbon composite material and lithium-ion battery technology, applied in the field of materials, can solve the problems of limited application, low compaction density, and material inability to withstand pressure, and achieve the effects of excellent cycle performance, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

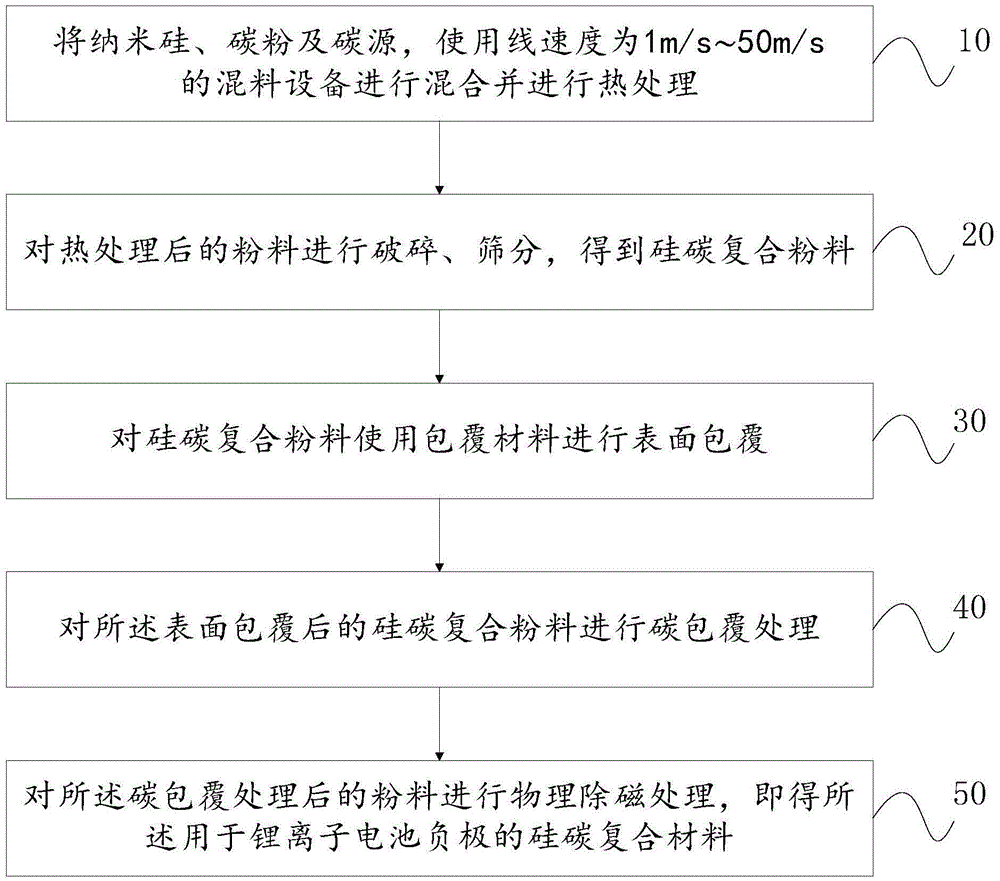

[0041] Embodiment 1 of the present invention provides a method for preparing a silicon-carbon composite material for a negative electrode of a lithium-ion battery, the preparation method comprising:

[0042] Step 10, mixing nano-silicon, carbon powder and carbon source using a mixing device with a line speed of 1m / s to 50m / s and performing heat treatment;

[0043] Wherein, the mass ratio of nano silicon is (0%, 50%], the mass ratio of carbon powder is (0%, 80%], and the mass ratio of carbon source is (0%, 80%];

[0044] The particle size distribution D50 of nano-silicon is 1nm-500nm, preferably 1nm-200nm. Nano-silicon is one or more of polycrystalline, monocrystalline or amorphous silicon powder; carbon powder is natural graphite, artificial graphite, flake graphite, microcrystalline graphite, graphitized mesophase carbon with D50=1 micron to 30 micron One or more mixtures of microspheres, expanded graphite, worm graphite, spherical graphite, graphite oxide, graphite chips, g...

Embodiment 2

[0065] The preparation method comprises the following steps (1)-(3).

[0066] (1) Nano-silicon (D50=80nm), coke A (D50=20 μm), and petroleum pitch are uniformly mixed in a ball mill, wherein the mass ratio of nano-silicon is 30%, coke is 60%, and the rest is pitch;

[0067] (2) The obtained material was heat-treated in a rotary kiln. The heat treatment method was to raise the temperature from room temperature to 200°C at a rate of 3°C / min, then to 900°C at a rate of 0.5°C / min, and finish after holding for 2 hours. During the heat treatment process, 0.1L / min of nitrogen is continuously fed as a protective atmosphere;

[0068] (3) After the material is pulverized, 3% coal tar pitch is mixed by a VC mixer, and then a mechanical fusion machine is used for fusion treatment, and the heat treatment method of step (2) is continued to obtain the silicon used for the negative electrode of lithium-ion batteries in this embodiment. carbon composites.

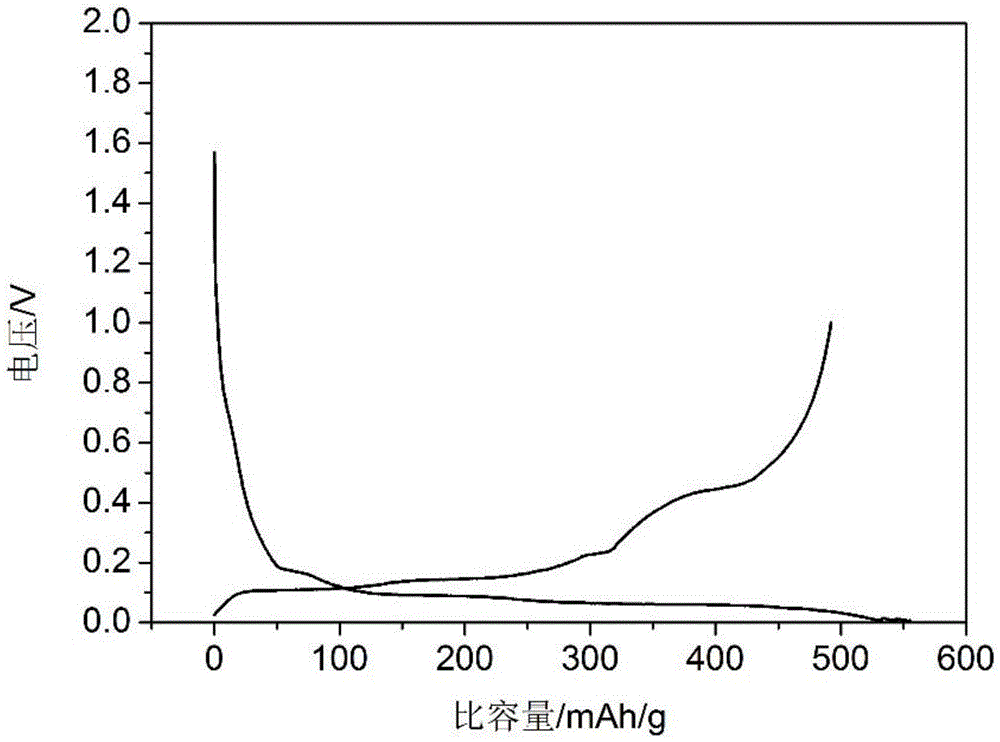

[0069] The prepared silicon-carbon...

Embodiment 3

[0075] The preparation method comprises the following steps (1)-(4).

[0076] (1) Mix nano-silicon powder (D50=80nm), hard carbon (D50=20 μm), and petroleum pitch in a high-speed VC mixer, wherein the mass ratio of nano-silicon is 15%, hard carbon is 70%, and the rest is pitch ;

[0077] (2) The obtained material was heat-treated in a rotary kiln. The heat treatment method was to raise the temperature from room temperature to 200°C at a rate of 3°C / min, then to 600°C at a rate of 1°C / min, and finish the heat preservation for 2 hours. During the heat treatment process, 0.1L / min of nitrogen is continuously fed as a protective atmosphere;

[0078] (3) After pulverizing the obtained material, 10% nano-copper oxide is mixed in by a VC mixer;

[0079] (4) The obtained material is mixed with 5% petroleum asphalt through a VC mixer, and heat treatment is continued. The heat treatment method is to heat up to 200°C from room temperature at a rate of 3°C / min, and then to 600°C at a rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com