Method for generating nano-copper particles on the surface of copper alloy film

A nano-copper and copper alloy technology, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of long experimental period, Cu particle pollution, unsuitable for industrialization development needs, etc., and the method is simple , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] First deposit Cu-Zr alloy film on polyimide PI substrate to form Cu-Zr / PI film-based system;

[0072] Then, for the prepared film-based system, the vacuum degree is better than 1*10 -3 Under the conditions, the temperature is 100-400 ° C, annealing for 5-10 minutes, so that pure Cu particles with nanometer or submicron scale are formed on the surface of the polyimide substrate film; or the prepared copper particles are oxidized to achieve oxidation. copper particles.

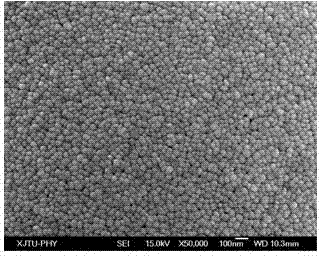

[0073] at a temperature of 360°C and 2 x 10 -4 Under the condition of Pa vacuum, the Cu-13.3 at. % Zr alloy film with a thickness of 50 nanometers on the polyimide substrate was annealed for 60 minutes to promote Cu atoms in the alloy film to precipitate, nucleate and grow into nanoscale Cu particles on the surface. Statistical results show that the average particle size is about 85 nanometers, and the particle spacing is relatively uniform.

Embodiment 2

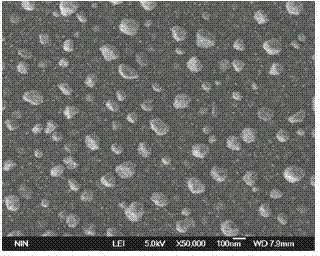

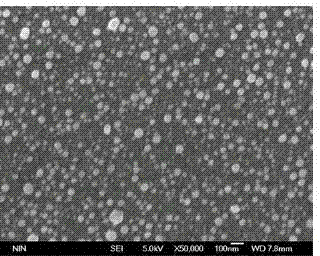

[0075] at a temperature of 330°C and 2 x 10 -4 Under Pa vacuum condition, the 50nm thick Cu-23.6 at. % Zr alloy film on the polyimide substrate was annealed for 60 minutes to promote the Cu atoms in the alloy film to precipitate, nucleate and grow into nanoscale Cu particles on the surface, Statistical results show that the average particle size is about 45 nanometers, the particle distribution is relatively dense, and the spacing is relatively uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com