Method for preparing nano-metallic copper powder

A technology of nano-metal and copper powder, which is applied in the field of preparation of nano-metal copper powder, to achieve the effect of simple and easy operation, short reaction time and low price in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

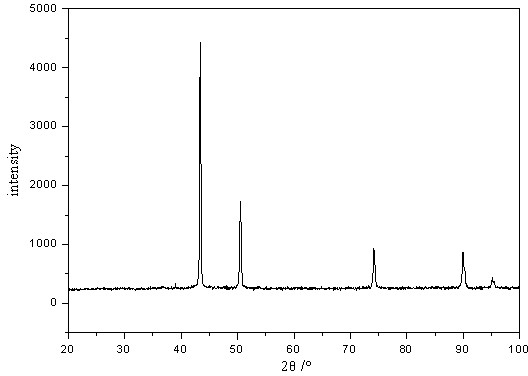

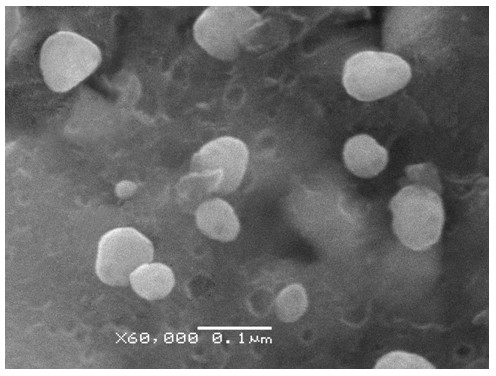

Image

Examples

preparation example Construction

[0030] The present invention is described further below by example, but does not limit the present invention. The operation steps of this preparation method are:

[0031] First add the copper salt into the stirring container, then add the reaction solvent and chelating agent into the stirring container, heat the stirring container so that the temperature of the stirring container reaches 70~90 °C, the speed is 1200 r / min, and under this condition Stir continuously until the sol is formed, then dry to gel in a drying oven at 80-100 °C, then grind the gel into powder, heat up to a certain temperature in a tube furnace for a certain period of time, and cool down to Take it out at room temperature to obtain nanometer copper powder.

[0032] Among them, the raw material required for the preparation is one or more mixtures of copper sulfate, basic copper carbonate, copper nitrate, copper chloride, copper carbonate, copper acetate; the solvent is deionized water; the chelating agent...

Embodiment 1

[0034] Put 5 g of copper nitrate in a beaker with a volume of 100 mL, add 20 mL of deionized water, then weigh 4 g of citric acid, dissolve it in 20 mL of deionized water, and then slowly add it to the copper nitrate solution. Place in a water bath stirrer, add ammonia water dropwise to adjust the pH to 4, then keep the temperature at 80 °C, and stir at a stirring speed of 1200 r / min until the wet gel is formed, and the wet gel is dried in a drying oven at 80 °C to dry gel. Grind the xerogel into a powder and weigh 8.5 g. The powdered xerogel was placed in a crucible and placed in a tube furnace, controlled by a program, and calcined at 300 °C for 1 h under argon protection, then cooled to room temperature, and taken out to obtain dark red copper powder, weighing 1.3 g.

Embodiment 2

[0036] Weigh 5 g of basic copper carbonate and place it in a beaker with a volume of 100 mL, add 40 mL of deionized water to dissolve, then weigh 2 g of lignin and dissolve it in 40 mL of deionized water, and slowly add the lignin solution to the alkali Formula copper carbonate solution, then add ammonia water dropwise to adjust the pH to 7, place the beaker in a water-bath stirring pot, stir at 80 °C until wet gel, then move to a drying oven at 90 °C to dry to gel. Grind the xerogel into powder and place it in a crucible, put it into a tube furnace, program temperature control, argon protection, calcinate at 200 °C for 1 h, cool down to room temperature, and take it out to obtain dark red copper powder, weighing 2.7 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com