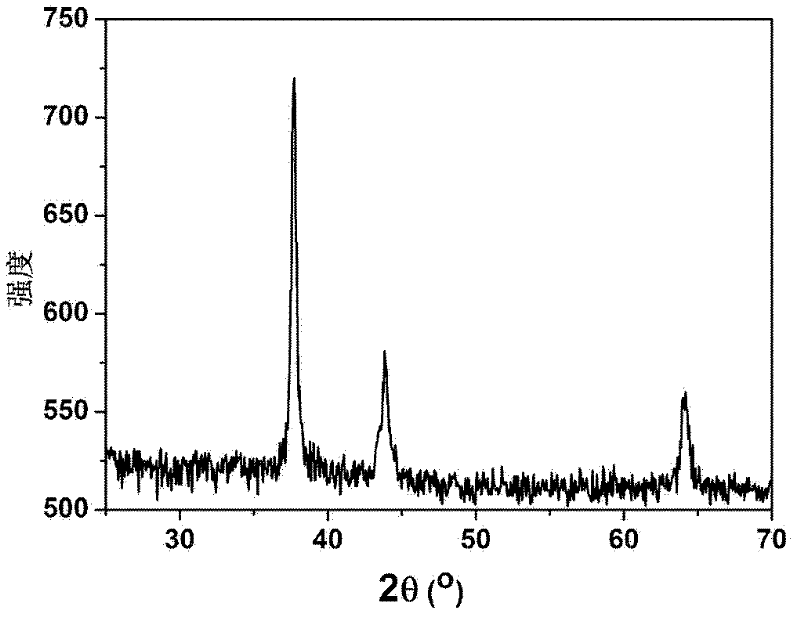

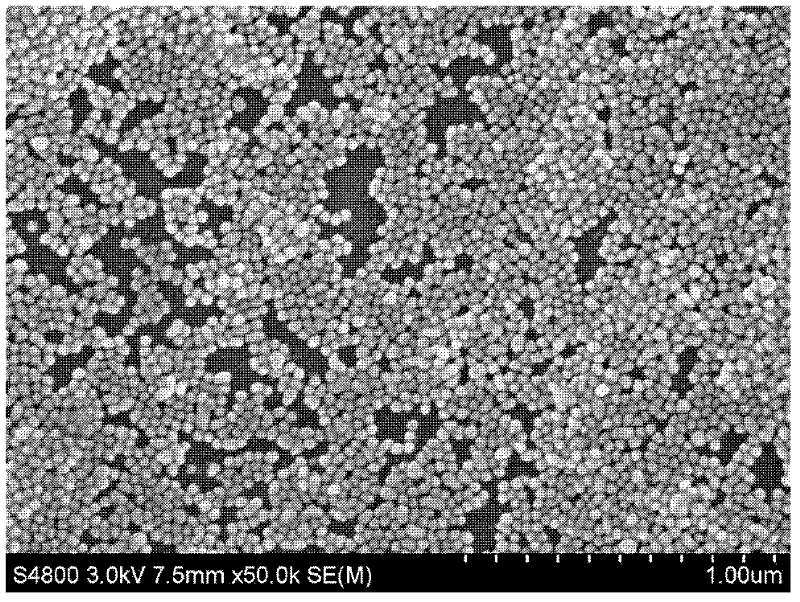

Method for preparing nanometer silver powder with accurately controlled particle size

A technology of precise control and particle size, applied in the field of inorganic chemical industry, can solve the problems of inability to pre-design the product size, decrease of production efficiency, difficulty in large-scale production, etc., and achieve the effect of increasing the total silver ion concentration, simple process and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) Preparation of seed crystals

[0053] Components of dispersant I: 5.0g trisodium citrate (17.0mmol)+6.7g polyvinylpyrrolidone (PVP K-30, 60.4mmol as a monomer)+18.0g sodium oleate (59.1mmol);

[0054] Reducing agent I solution: a fresh solution prepared from 225 mg sodium borohydride (5.9 mmol) and 330 mL water, wherein the concentration of sodium borohydride is about 17.9 mmol / L, and the molar ratio of sodium borohydride to silver nitrate in mixed solution I is 1:1 .

[0055] Described dispersant I and 1.0g silver nitrate (5.9mmol) are dissolved in 25.0L water and form mixed solution I (wherein the mol ratio of dispersant I and silver nitrate is 23.1: 1, the concentration of silver nitrate is about 0.2mmol / L ), under rapid stirring, then quickly add the reducing agent I solution, stir and react at room temperature for 10 minutes, and use it as a seed crystal for subsequent use.

[0056] (2) Preparation of silver-containing precursor

[0057] ① The complexing age...

Embodiment 2

[0074] (1) Preparation of seed crystals

[0075] The composition of dispersant I: 2.5g trisodium citrate (8.5mmol)+3.3g polyvinylpyrrolidone (PVP K-30, 29.7mmol in monomer)+9.0g sodium oleate (29.6mmol);

[0076] The reducing agent I solution is: a fresh solution prepared by 115mg sodium borohydride (3.0mmol) and 165mL water, wherein the concentration of sodium borohydride is about 18.4mmol / L, and the molar ratio of sodium borohydride to silver nitrate in mixed solution I is about 1:1 ;

[0077] The dispersant I and 500mg silver nitrate (2.94mmol) were dissolved in 12.5L water to form mixed solution I (wherein the mol ratio of dispersant I to silver nitrate was 23:1, and the concentration of silver nitrate was about 0.2mmol / L) , under rapid stirring, then quickly add the reducing agent I solution, stir and react at room temperature for 10 minutes, and use it as a seed crystal for later use.

[0078] (2) Preparation of silver-containing precursor

[0079] ① Prepare the mixed...

Embodiment 3

[0084] (1) Preparation of seed crystals

[0085] The composition of the dispersant I: 1.25g trisodium citrate (4.2mmol)+1.67g polyvinylpyrrolidone (PVP K-30, 15.0mmol in monomer)+4.5g sodium oleate (14.8mmol);

[0086] Reducing agent I solution: a fresh solution prepared by 56mg sodium borohydride (1.48mmol) and 82.0mL water, wherein the concentration of sodium borohydride is about 18.0mmol / L, and the molar ratio of sodium borohydride to silver nitrate in mixed solution I is about 1:1 .

[0087] Dispersant I and 250mg silver nitrate (1.47mmol) were dissolved in 6.25L water to form mixed solution I (wherein the molar ratio of dispersant I to silver nitrate was 23:1, and the concentration of silver nitrate was about 0.2mmol / L), quickly Under stirring, quickly add the reducing agent I solution, stir and react at room temperature for 10 minutes, and use it as a seed crystal for later use.

[0088] (2) Preparation of silver-containing precursor

[0089] ① Prepare the mixed solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com