Preparation method and application of core-shell structure cobalt-base catalyst of middle distillate for synthesis gas preparation

A technology of cobalt-based catalysts and middle distillates, which is applied in the preparation of liquid hydrocarbon mixtures, physical/chemical process catalysts, metal/metal oxides/metal hydroxide catalysts, etc., to achieve high yield, good dispersion, and selectivity sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

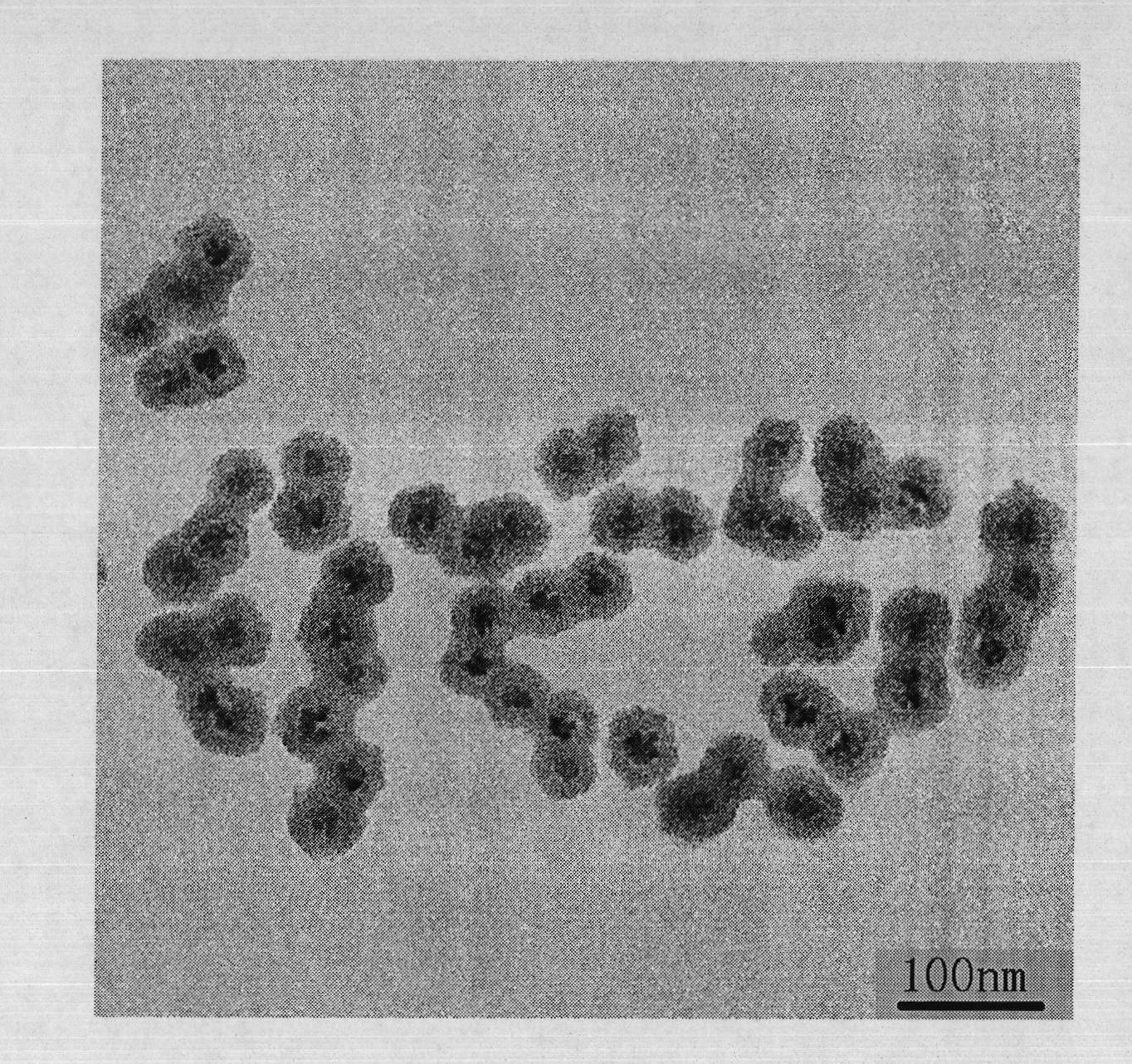

[0019] Dissolve 3g of cobalt nitrate and 6g of polyvinylpyrrolidone 4000 in 800mL of absolute ethanol, respectively, and transfer them to a polytetrafluoroethylene-lined reactor. React in a homogeneous reactor at 180° C. for 4 hours, and after cooling, transfer the above solution into a beaker to obtain an ethanol suspension containing cobalt tetraoxide nanoparticles. Then, 2L of absolute ethanol, 1.6L of deionized water, 150mL of ammonia water, and 6g of cetyltrimethylammonium bromide were added to the above ethanol suspension, and after stirring for a period of time, 20mL of ethyl orthosilicate was added. After reacting for a period of time, it was filtered, dried, ground, and calcined at 500°C for 6 hours to obtain a cobalt-based catalyst with a core-shell structure, which was named C-1.

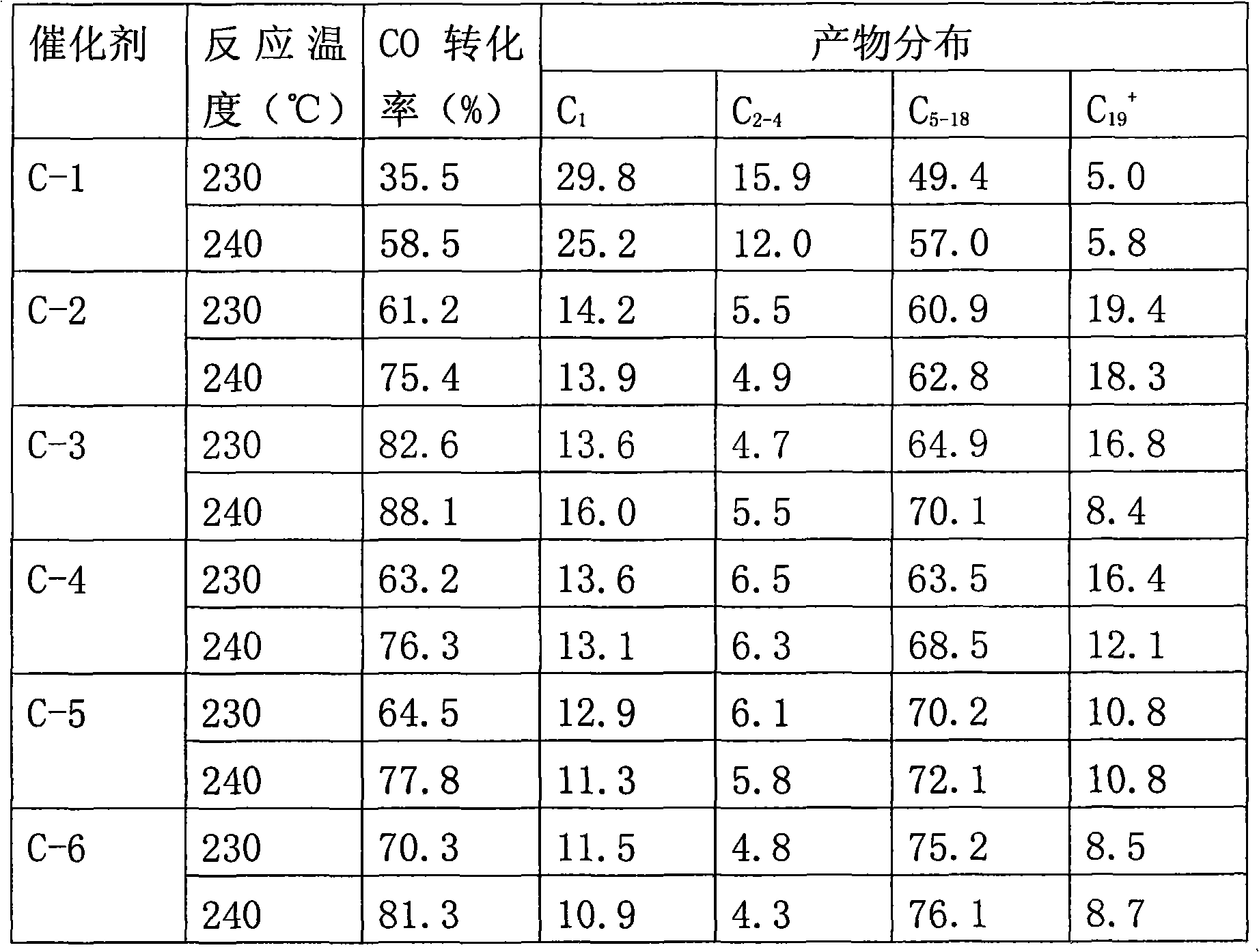

[0020] Catalyst evaluation experiment In a pressurized fixed-bed reactor, pure hydrogen was used for temperature-programmed reduction at 300°C, and after cooling down, it was replaced wit...

Embodiment 2

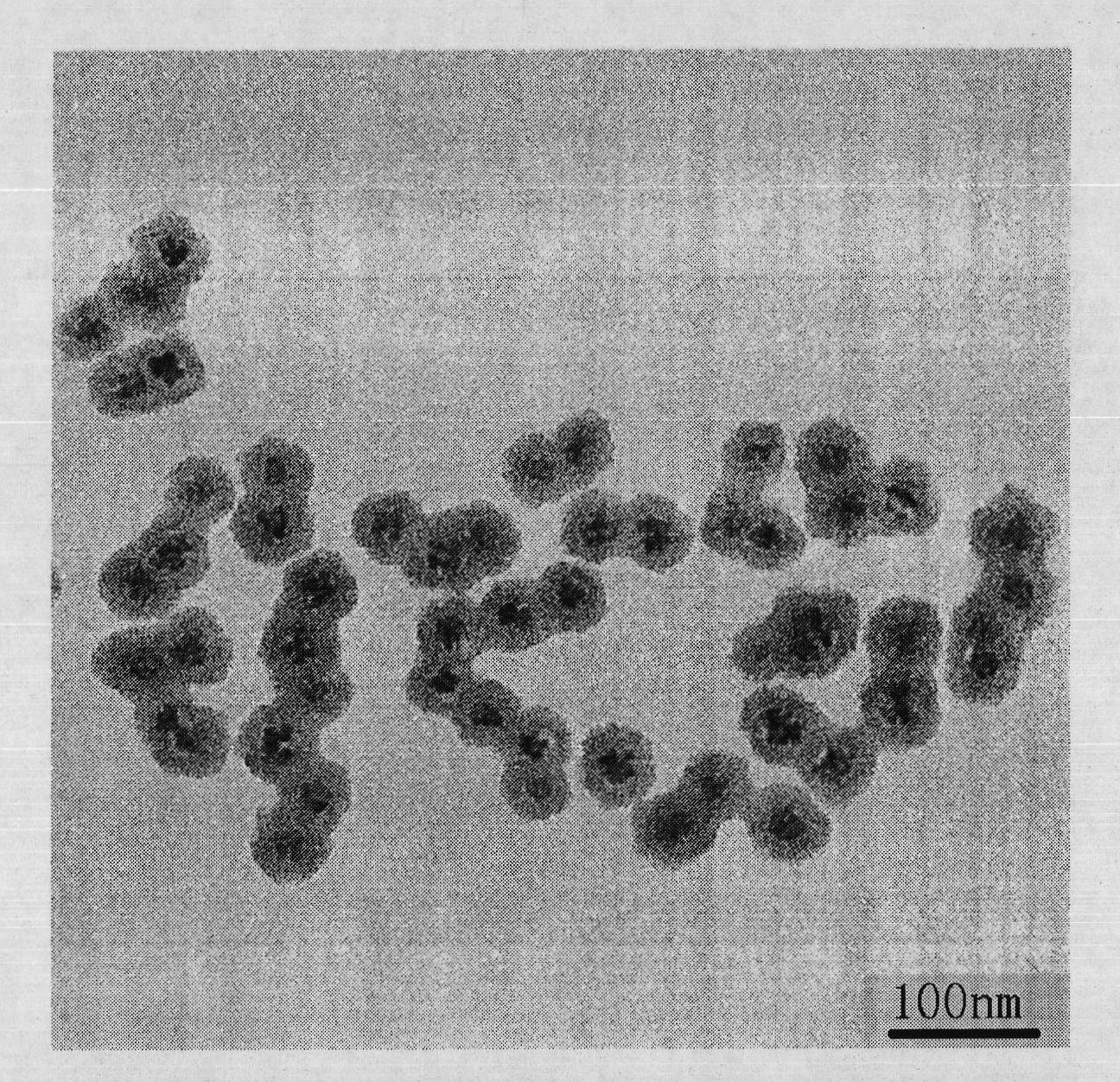

[0022] Dissolve 7g of cobalt acetate and 14g of polyvinylpyrrolidone 10000 in 700mL of absolute ethanol, respectively, and then transfer to a polytetrafluoroethylene-lined reactor. React in a homogeneous reactor at 190° C. for 3 hours, and after cooling, transfer the above solution into a beaker to obtain an ethanol suspension containing cobalt tetroxide nanoparticles. Then add 2L of absolute ethanol, 1L of deionized water, 150mL of ammonia water, and 5g of cetyltrimethylammonium bromide to the above-mentioned ethanol suspension, and after stirring for a period of time, add 10mL of ethyl orthosilicate. After reacting for a period of time, filter, dry, grind, and bake at 400°C for 5 hours to obtain a cobalt-based catalyst with a core-shell structure, which is named C-2.

[0023] Catalyst evaluation experiment In a pressurized fixed-bed reactor, pure hydrogen was used for temperature-programmed reduction at 350°C, and after cooling down, it was replaced with synthesis gas for re...

Embodiment 3

[0025] Dissolve 13g of cobalt nitrate and 26g of polyvinylpyrrolidone 40000 in 1L of absolute ethanol, and then transfer them to a Teflon-lined reactor. React in a homogeneous reactor at 180° C. for 2 hours, and after cooling, transfer the above solution into a beaker to obtain an ethanol suspension containing cobalt tetroxide nanoparticles. Then add 1.5L of absolute ethanol, 1.5L of deionized water, 100mL of ammonia water, and 4g of cetyltrimethylammonium bromide to the above-mentioned ethanol suspension, and after stirring for a period of time, add 15mL of ethyl orthosilicate. After reacting for a period of time, filter, dry, grind, and bake at 550°C for 4 hours to obtain a cobalt-based catalyst with a core-shell structure, which is named C-3.

[0026] Catalyst evaluation experiment In a pressurized fixed-bed reactor, the pure hydrogen was used to reduce the temperature at 400°C by temperature programming, and after cooling down, it was replaced with synthesis gas for reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com