SiO2/TiO2 hollow compound structural material as well as preparation method and uses thereof

A composite structure and hollow technology, which is applied in the field of inorganic nanomaterial preparation, can solve the problems of application limitations and achieve the effects of improved utilization rate, simple manufacturing method and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

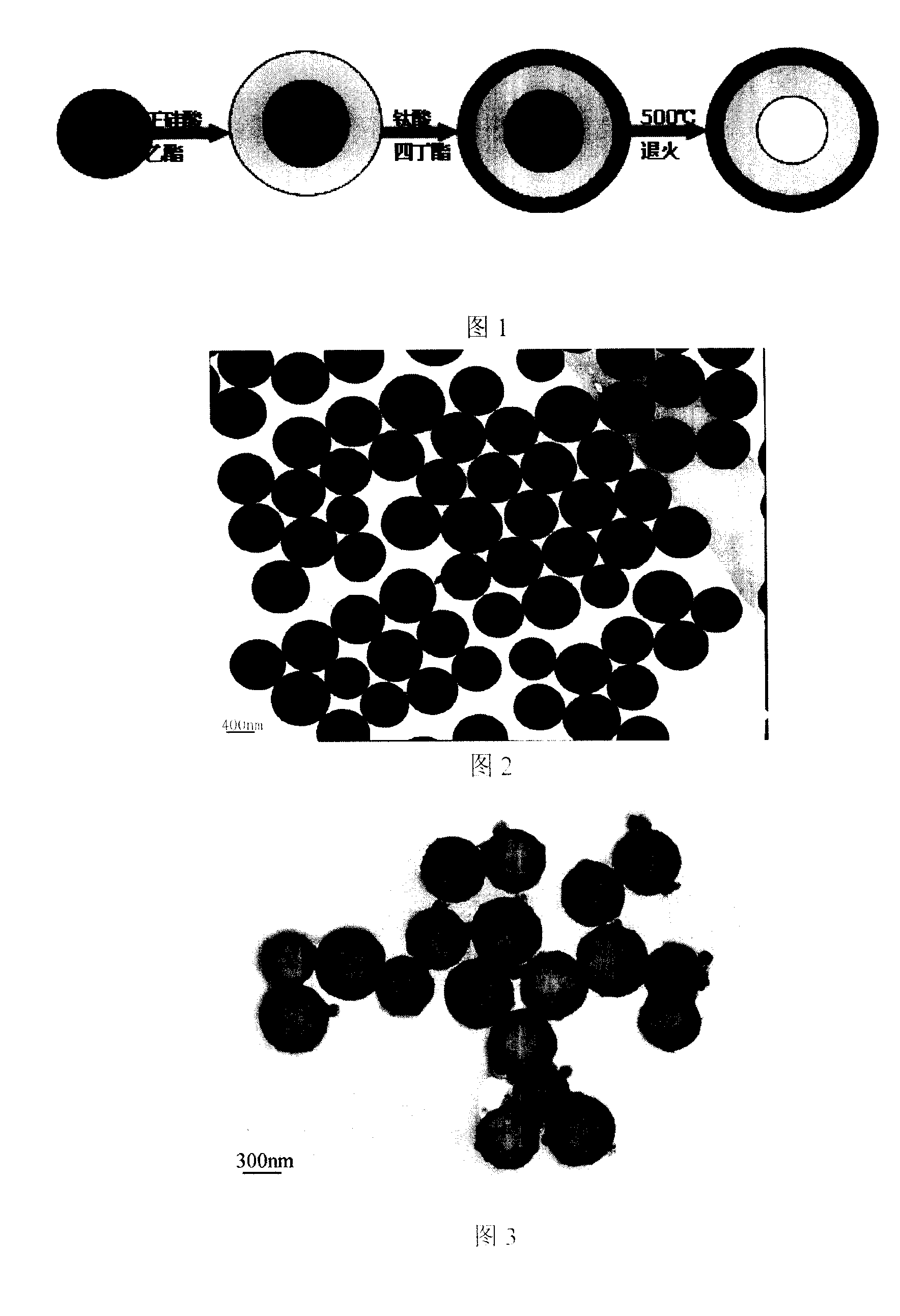

[0037] A SiO 2 / TiO 2 The hollow composite structural material is prepared by the following steps,

[0038] 1) Preparation of carbon nanospheres

[0039] Weigh 4 parts by weight of glucose, dissolve it in 40 parts by volume of water, transfer it to a stainless steel reaction kettle lined with polytetrafluoroethylene, close the reaction kettle, and place it in a resistance furnace at 160°C for 12 hours. After the reaction is completed, cool it naturally To room temperature, pour out the product in the kettle, centrifuge at 10,000 rpm for 3 minutes, take the precipitate, wash with deionized water and absolute ethanol three times each, and vacuum dry at 60°C for 4 hours to obtain a particle size of 200nm monodisperse carbon nanospheres;

[0040] 2) Carbon nanospheres coated with silica

[0041] Weigh 0.05 parts by weight of carbon nanospheres prepared in step (1), disperse them in a solution mixed with 20 parts by volume of ethanol and 4 parts by volume of water, add 1.5ml of...

Embodiment 2

[0047] A SiO 2 / TiO 2 The application of hollow composite structural materials is prepared into SiO by the following method 2 / TiO 2 Hollow composite structural material membrane to achieve:

[0048] 1)SiO2 2 / TiO 2 Fabrication of Hollow Composite Structural Films

[0049] SiO prepared by Example 1 2 / TiO 2 The hollow composite structure material is ultrasonically dispersed in water to form a solution with a mass fraction of 0.4%, and a common glass slide is used as a substrate to prepare a layer of thin film by vertical pulling method.

[0050] 2) Anneal the film prepared by step 1) at 450°C for 1h to obtain SiO 2 / TiO 2 Hollow Composite Structural Material Membranes.

Embodiment 3

[0052] A SiO 2 / TiO 2 The hollow composite structural material is prepared by the following steps,

[0053] 1) Preparation of carbon nanospheres

[0054] Weigh 8 parts by weight of glucose, dissolve it in 40 parts by volume of water, transfer it to a stainless steel reaction kettle lined with polytetrafluoroethylene, close the reaction kettle, and place it in a resistance furnace at 200°C for 4 hours of reaction. After the reaction is completed, cool it naturally To room temperature, pour out the product in the kettle, centrifuge at 10,000 rpm for 3 minutes, take the precipitate, wash with deionized water and absolute ethanol three times each, and vacuum dry at 60°C for 4 hours to obtain a particle size of 200nm monodisperse carbon nanospheres;

[0055] 2) Carbon nanospheres coated with silica

[0056] Weigh 0.1 parts by weight of the carbon nanospheres prepared in step (1), disperse them in a solution mixed with 40 parts by volume of ethanol and 8 parts by volume of water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com