Crystallizer for MVR (Mechanical Vapor Recompression) sewage treatment system

A sewage treatment system and crystallizer technology, applied in water/sewage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as uneven distribution, blockage of mist eliminator, and reduced service life , to improve the effect of vapor-liquid separation, increase the crystallization time, and improve the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

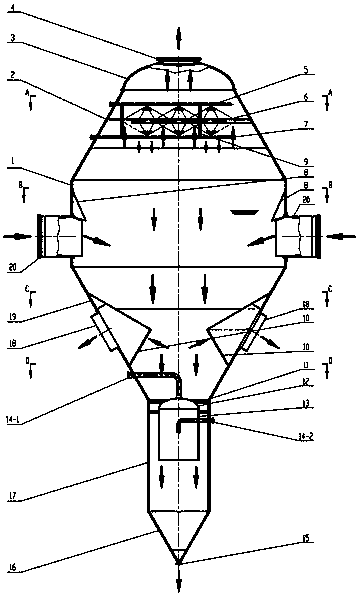

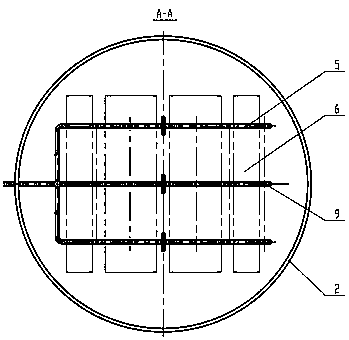

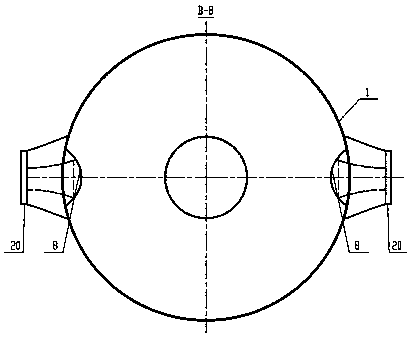

[0056] Such as figure 1 , figure 2 , image 3 and Figure 5 Shown, the present invention comprises cylindrical cylinder body 1, is provided with 2 solution inlet pipes 20 on the circumference of cylinder body 1, is welded with upper cone 2 at the top of cylinder body 1, welds on the top of upper cone body 2 There is an upper head 3, a steam outlet pipe 4 is arranged at the center of the top of the upper head 3, a lower cone 19 is welded on the lower part of the cylinder body 1, and a solution outlet pipe 18 is welded on the lower cone 19, and at the bottom of the lower cone 19 A salt leg 17 is welded below, a small cone 16 is welded at the bottom of the salt leg 17, a salt slurry outlet 15 is provided at the bottom of the small cone 16, and the interface position between the inner wall of the cylinder body 1 and the two solution inlet pipes 20 A guide shunt 8 is welded, and a multi-channel folded-plate demister 6 is installed inside the upper cone 2. An upper sprayer 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com