Perovskite thin film, preparation method thereof and perovskite solar cell

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of insufficient time for perovskite precursors, short solvent volatilization time, and poor control of the state of perovskite precursors, and achieve crystallization time. Long, slow evaporation time, improve performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation steps of the perovskite thin film are as follows:

[0041] 1) First, the perovskite precursor solution is spin-coated on the ITO conductive glass; the solvent selected for the perovskite precursor solution is DMF, and a 40nm PEDOT:PSS dense layer is formed on the ITO conductive glass;

[0042] 2), then spin the substrate coated with the perovskite precursor solution, stop the rotation when the perovskite precursor solution is not completely volatilized, and place it for a certain period of time, the time is 0s;

[0043] 3) Re-spin the substrate coated with the perovskite precursor solution, then drop toluene as an anti-solvent, and anneal at 100° C. for 10 minutes to form a perovskite film.

Embodiment 2

[0045] This embodiment is basically consistent with Embodiment 1, the difference is:

[0046] Change the placement time in step 2), and the placement time is controlled to 10s.

Embodiment 3

[0048] This embodiment is basically consistent with Embodiment 1, the difference is:

[0049] Change the placement time in step 2), and the placement time is controlled to 30s.

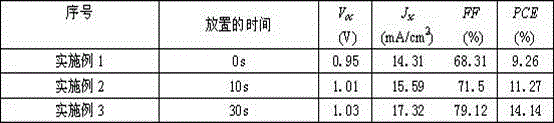

[0050]The perovskite thin films prepared in the above-mentioned Examples 1, 2 and 3 are used to prepare perovskite solar cells respectively, and the perovskite solar cells made include successively from bottom to top: ITO conductive glass, 40nm PEDOT:PSS Dense layer, 300nm thick CH 3 NH 3 PB 0.85 Cl 0.15 (that is, perovskite film), 30nm thick PCBM (fullerene derivative), 10nm thick PEIE and 90nm thick Ag, the effective area of perovskite solar cells is 0.045cm 2 , the energy conversion efficiency of perovskite solar cells is shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com