Storage-stable liquid pure MDI composition as well as preparation method and application thereof

A technology with stable storage and composition, applied in the field of isocyanates, can solve the problems affecting the quality of polyurethane products, prolong the shelf life, and reduce the effective components, so as to improve the oxidation resistance and yellowing, improve the resistance to low temperature crystallization, and have no impact on product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] To prepare a storage-stable liquid pure MDI composition:

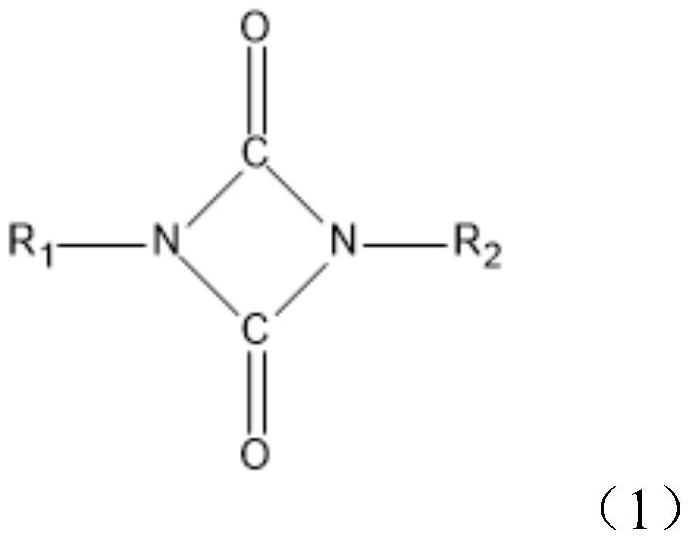

[0070] To 500 g of fresh diphenylmethane diisocyanate (2,4-MDI 1 wt%, 4,4-MDI 99 wt%), add 0.4 g BHT and 0.2 g TPP, and add 0.5 g 1-(4,4'-diphenyl Methyl methane isocyanate)-3-(6-hexylidene isocyanate)-1,3-diazacyclo-2,4-butanedione (A-1), stirred at 55°C for 2h to obtain a transparent and clear solid-free 200g of the liquid pure MDI composition were packaged in 250ml transparent glass bottles, and then placed in ovens at 40°C and 45°C respectively, and stored for more than 100 days. The composition remained liquid and clear, and the liquid pure MDI composition The performance test data are shown in Table 1.

[0071] Preparation of isocyanate prepolymers resistant to low temperature crystallization:

[0072] The above 100g liquid pure MDI composition was reacted with 65g CMA254 at 70°C for 3h, then 15g liquefied MDI was added and stirred at 55°C for 0.5h to obtain an isocyanate prepolymer. No crystallization occ...

Embodiment 2

[0074] To prepare a storage-stable liquid pure MDI composition:

[0075] To 500 g of fresh diphenylmethane diisocyanate (2,4-MDI 1 wt%, 4,4-MDI 99 wt%), add 1.0 g BHT and 0.5 g TPP, and add 5 g 1-(4,4'-diphenyl Methane isocyanate)-3-(6-hexylidene isocyanate)-1,3-diazacyclo-2,4-butanedione (A-1), stirred at 55°C for 2h to obtain a transparent and clear solid-free Liquid pure MDI composition, respectively package 200g in 250ml transparent glass bottles, and then place them in ovens at 40°C and 45°C respectively, and store them for more than 180 days. The test data are shown in Table 1.

[0076] Preparation of isocyanate prepolymers resistant to low temperature crystallization:

[0077] React the above 100g liquid pure MDI composition with 65g polyethylene adipate at 80°C for 2h, then add 20g liquefied MDI and stir at 55°C for 0.5h to obtain an isocyanate prepolymer, and place it at 25°C No crystallization occurred within 137h.

Embodiment 3

[0079] To prepare a storage-stable liquid pure MDI composition:

[0080] To 500 g of fresh diphenylmethane diisocyanate (2,4-MDI 1 wt%, 4,4-MDI 99 wt%), add 0.4 g BHT and 0.2 g TPP, and add 5 g 1-(4,4'-diphenyl Methaneisocyanate)-3-(3-isocyanatomethylene-3,5,5-trimethylcyclohexyl)-1,3-diazacyclo-2,4-butanedione (A-2), Stir at 55°C for 2 hours to obtain liquid pure MDI compositions with transparent, clear and solid-free color, respectively package 200g in 250ml transparent glass bottles, and then place them in ovens at 40°C and 45°C respectively, and store them for more than 260 days. Still keep liquid state and clear and transparent, the performance test data of liquid pure MDI composition are as shown in table 1.

[0081] Preparation of isocyanate prepolymers resistant to low temperature crystallization:

[0082] The above 100g liquid pure MDI composition was reacted with 60g polyethylene glycol-1,4-butanediol adipate at 75°C for 2.5h, then 15g liquefied MDI was added and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com