High-crystallized and high-temperature-resistant self-lubricating material based on PA66, composite board and preparation method of composite board

A self-lubricating material, PA66 technology, applied in the field of wear-resistant plates, can solve the problems of uneven grain size, affecting wear resistance, reducing mechanical properties, etc., to achieve sufficient grain growth, fast heat transfer, and uniform grain structure and shape effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

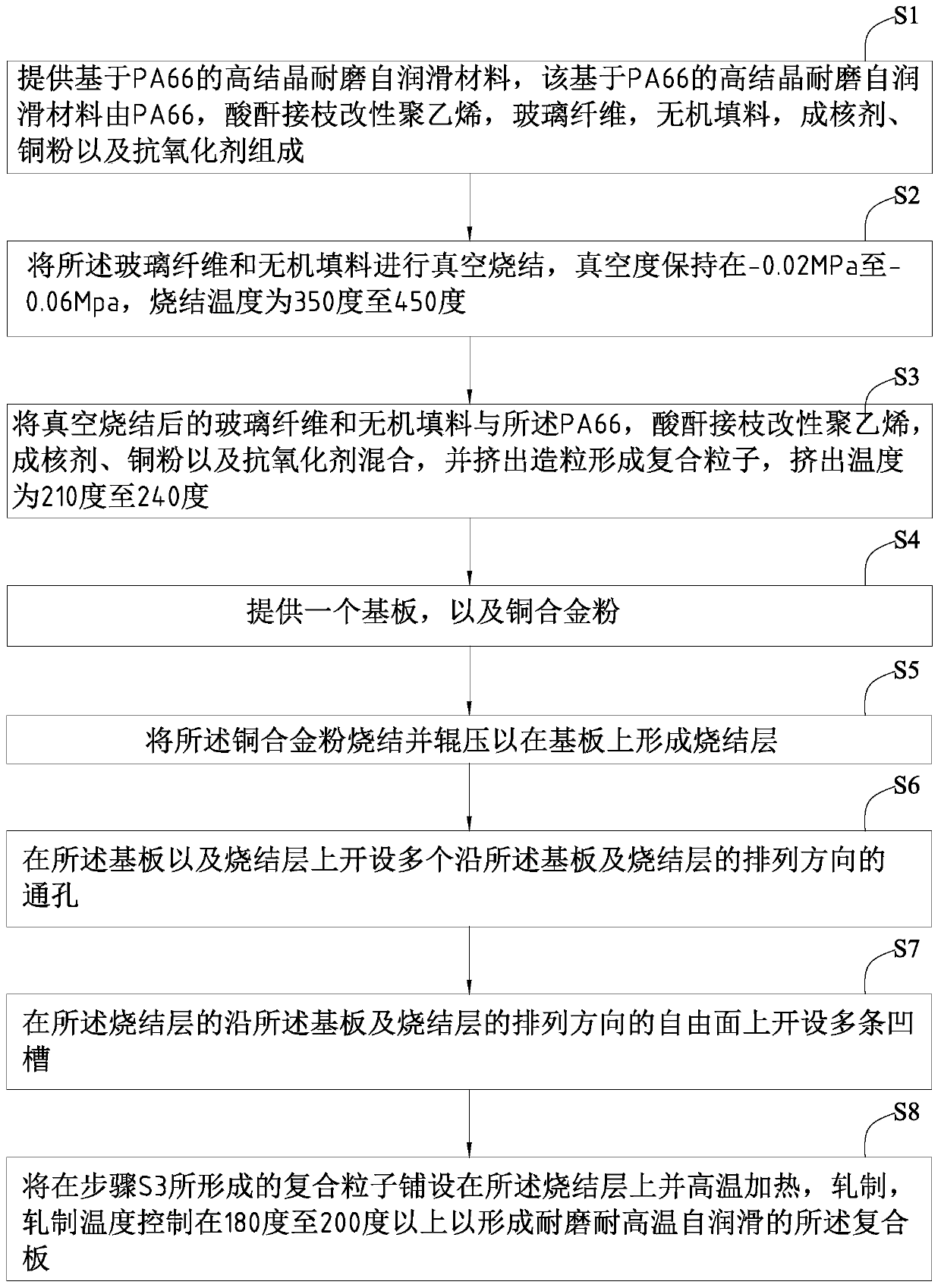

[0027] The high crystallization high temperature resistant self-lubricating material based on PA66 provided by the invention is composed of PA66, acid anhydride graft modified polyethylene, glass fiber, inorganic filler, nucleating agent and antioxidant. Specifically, the weight percentage of the PA66 is 56.9% to 84.89%, the weight percentage of the anhydride graft modified polyethylene is 5% to 10%, and the weight percentage of the glass fiber is 5% to 15%. The weight percentage of the inorganic filler is 5%-15%, the weight percentage of the nucleating agent is 0.01-0.10%, and the weight percentage of the antioxidant is 0.1%-3%. The PA66 is a kind of thermoplastic resin containing amide groups (—CONH—), which is widely used in the field of friction and wear due to its good wear resistance. As we all know, for a skateboard or a sliding bearing, its anti-friction performance is one of its most important parameters, which determines the life of the skateboard or sliding bearing....

specific Embodiment

[0042] The formula data table of each embodiment of table one

[0043] name PA66 Anhydride graft modified polyethylene Nucleating agent glass fiber Barium sulfate Example 1 59.9 copies 12 copies 0.1 18 copies 10 copies Example 2 69.9 copies 12 copies 0.1 13 copies 5 copies comparative example 100 copies —— —— —— ——

Embodiment 1

[0045] Step 1: Weigh 59.9 parts of PA66, 12 parts of polyethylene with maleic anhydride graft ratio of 3%, 18 parts of sintered glass fiber and 10 parts of barium sulfate, and 0.1 parts of nano-copper powder with a particle size of 80nm share.

[0046] Step 2: Add all the above-mentioned raw materials into a high-speed mixer with a rotation speed of 350 rpm and mix for 20 minutes to obtain a mixture.

[0047] Step 3: Extrude and granulate the above mixture through a twin-screw extruder at an extrusion temperature of 230°C.

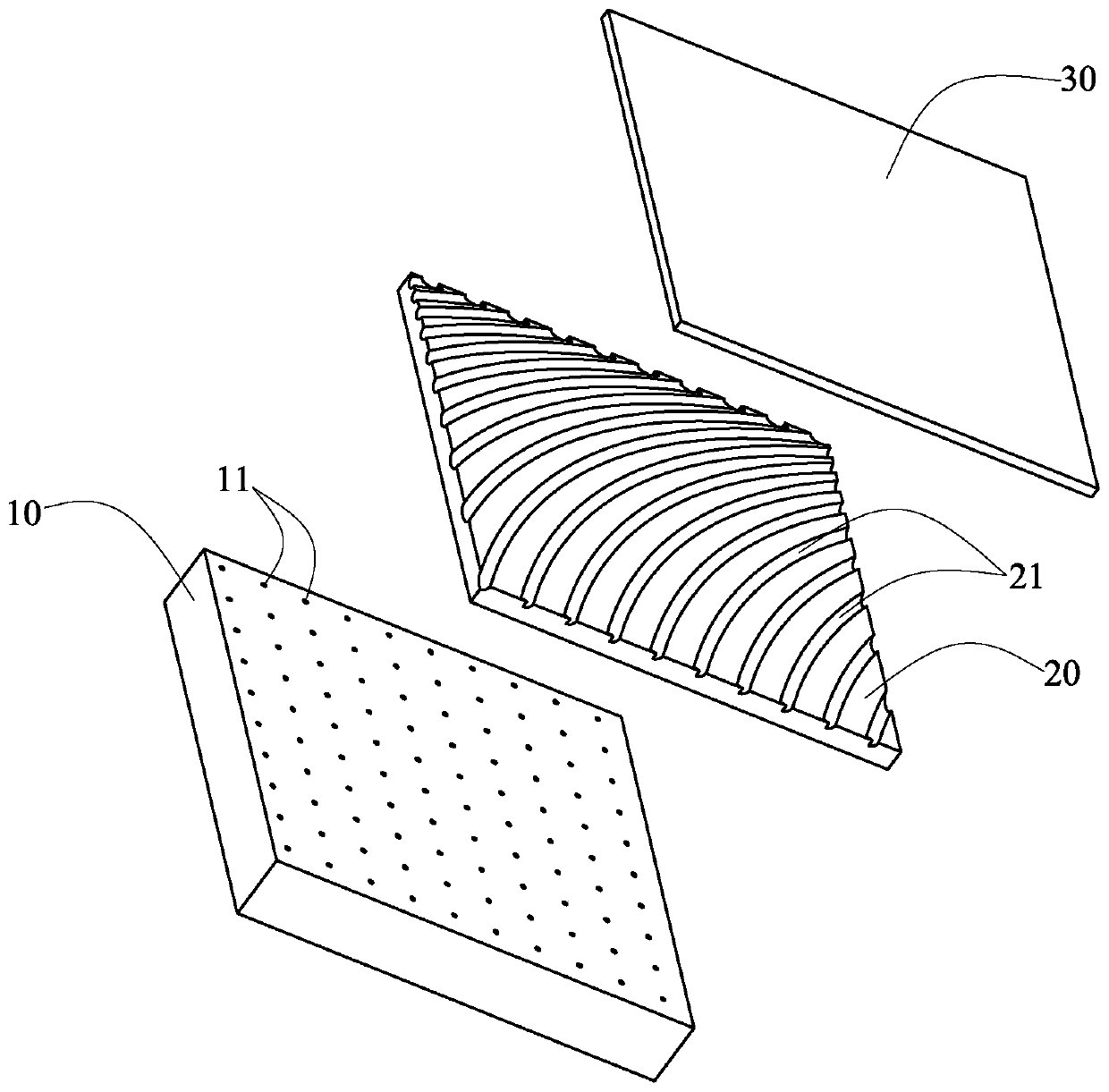

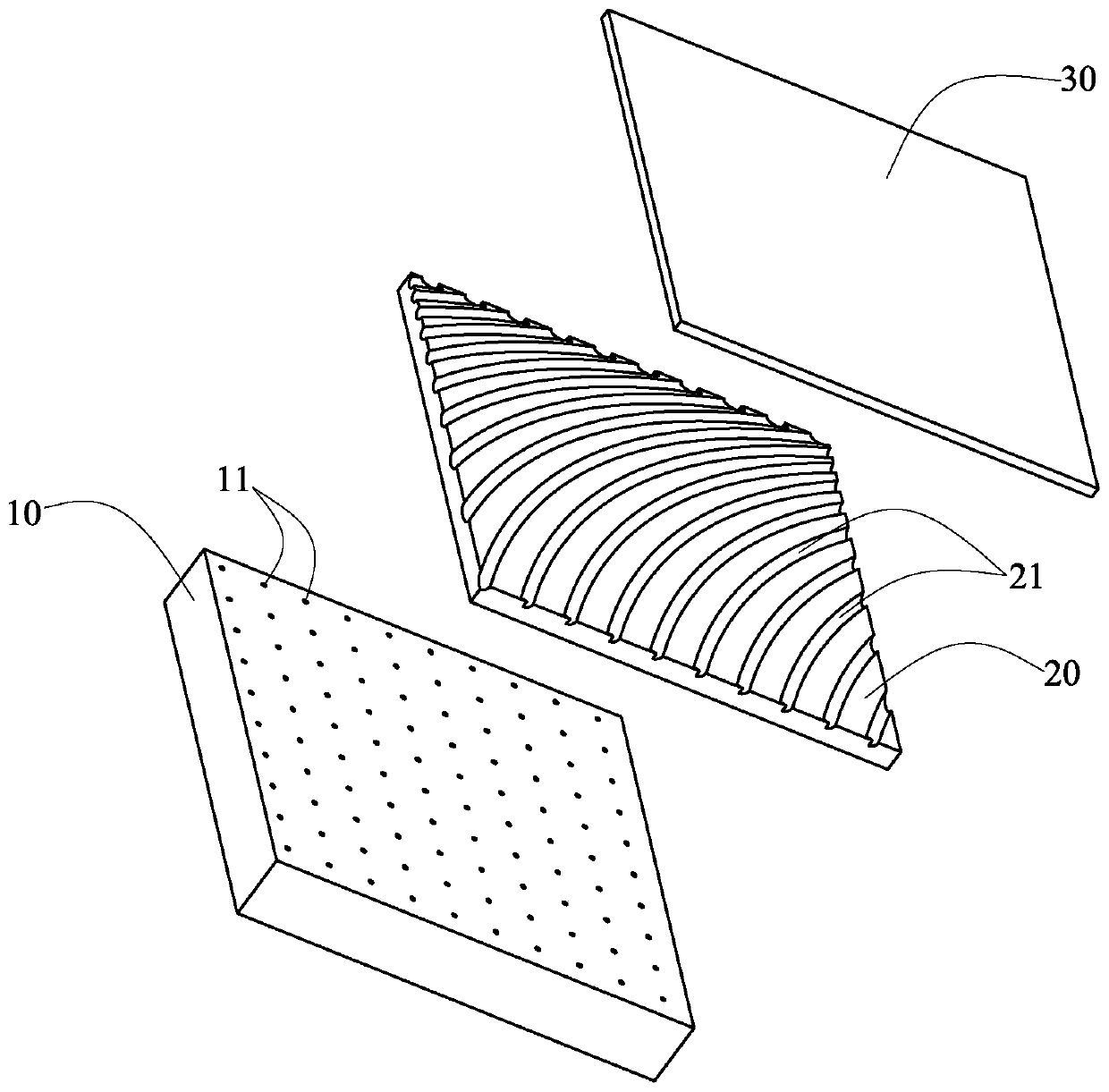

[0048] Step 4: Lay the obtained particles on the surface of the plate for melting and sintering, and carry out composite processing at a rolling temperature of normal temperature to obtain a three-layer composite plate with good wear resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com