A kind of crystallization purification method of 7-dehydrocholesterol and its application in the production of vd3

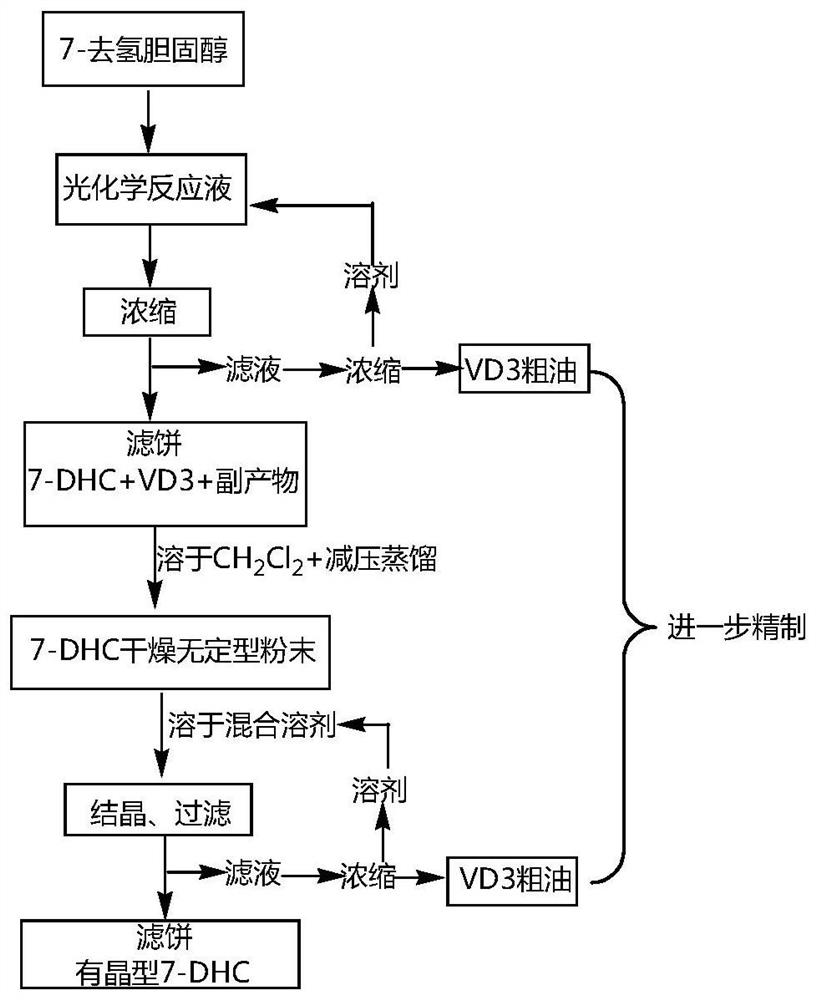

A dehydrocholesterol and purification method technology, which is applied in the field of purification and preparation of 7-dehydrocholesterol, the raw material for vitamin D3 production, can solve the problems of increased viscosity of the photochemical reaction system, increased probability of "occlusion", and long operation cycle, etc., to achieve purification The process is mild and controllable, it is convenient for filtration and washing, and the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

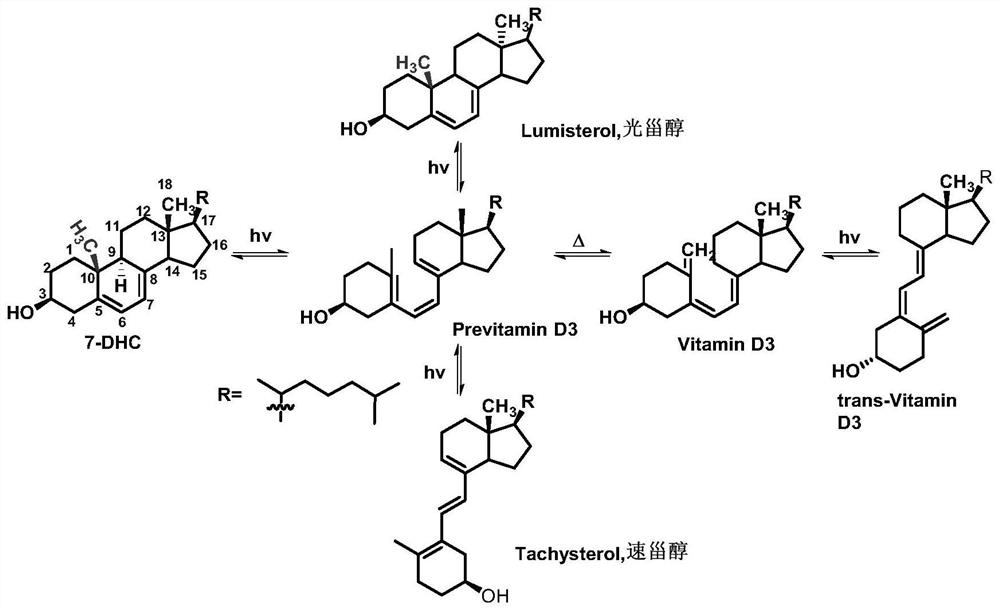

Method used

Image

Examples

Embodiment 1

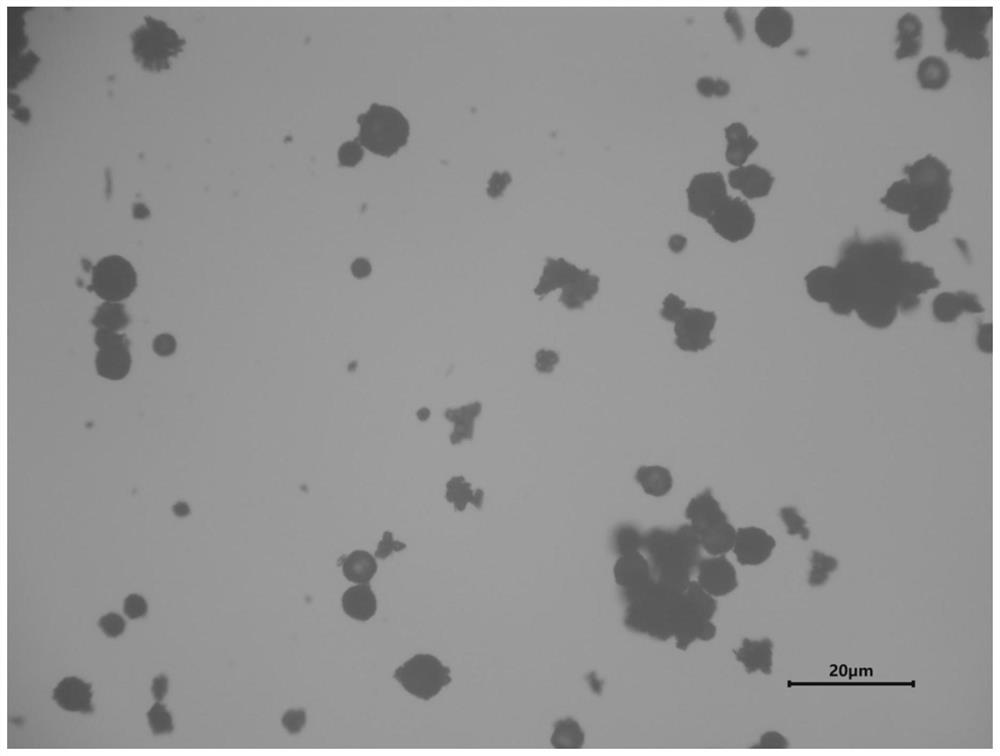

[0053] 45g 7-dehydrocholesterol with a content of 96% was added to a mixed solvent of 1544g methanol (70wt%) and 661g (30wt%) n-hexane to obtain a 7-dehydrocholesterol solution with a mass fraction of 2%, and the photochemical reactor was turned on , control the temperature of the reactor to be 40 ° C, and use the metering pump to pass the configured 7-dehydrocholesterol solution into the photochemical reactor. After the reaction is completed, a solution of pre-vitamin D3 is obtained, and the solution is heated at 60 ° C and refluxed for 1 hour, and then concentrated And reclaim methanol and n-hexane mixed solvent, filter and separate to obtain 7-dehydrocholesterol crude product 40g (7-dehydrocholesterol content is 86%, vitamin D3 content is 8%), see the crystal photo image 3 .

[0054] Use 180 g of solvent dichloromethane to dissolve the above-mentioned crude 7-dehydrocholesterol, set the external temperature of the water bath at 25°C, and remove the solvent by reducing the ...

Embodiment 2

[0067] 45 g of 7-dehydrocholesterol with a content of 96% was added to 4455 g of methanol to obtain a 7-dehydrocholesterol solution with a mass fraction of 1%. The photochemical reactor was turned on, and the temperature of the reactor was controlled to be 40°C. The 7-dehydrocholesterol solution was passed into the photochemical reactor, and after the reaction was completed, a solution of pre-vitamin D3 was obtained, and the solution was heated to 60 ° C and refluxed for 1 hour, then concentrated and recovered methanol and n-hexane solvent, and 7-dehydrogenation was obtained by filtration and separation Crude cholesterol 30g (7-dehydrocholesterol content is 90%, vitamin D3 content is 6%).

[0068] Use solvent dichloromethane 180g to dissolve above-mentioned 7-dehydrocholesterol crude product, set 25 ℃ of water bath external temperature, reduce the pressure of 200mbar to evaporate the solvent, obtain amorphous 7-dehydrocholesterol powder; configure n-hexane / methanol (n-hexane). ...

Embodiment 3

[0070] 45g 7-dehydrocholesterol with a content of 96% was added to a mixed solvent of 1544g methanol (70wt%) and 661g (30wt%) n-hexane to obtain a 7-dehydrocholesterol solution with a mass fraction of 2%, and the photochemical reactor was turned on , control the temperature of the reactor to be 40 ° C, use the metering pump to pass the configured 7-dehydrocholesterol solution into the photochemical reactor, after the reaction is completed, obtain a solution of pre-vitamin D3, heat the solution to reflux for 1 hour, then concentrate and recover Methanol and n-hexane were mixed solvent, and the concentrated product was filtered and separated to obtain 40 g of crude 7-dehydrocholesterol (the content of 7-dehydrocholesterol was 86%, and the content of vitamin D3 was 8%).

[0071] Use solvent dichloromethane 180g to dissolve above-mentioned 7-dehydrocholesterol crude product, set 25 ℃ of water bath external temperature, reduce the pressure of 200mbar to evaporate the solvent, obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com