Low-temperature polycrystalline silicon thin film transistor and preparation method thereof

一种薄膜晶体管、低温多晶硅的技术,应用在晶体管、半导体/固态器件制造、电固体器件等方向,能够解决多晶硅晶粒尺寸小、多晶硅实际应用限制等问题,达到提升驱动效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This embodiment provides a low temperature polysilicon thin film transistor, the thin film transistor includes a pixel thin film transistor and a driving thin film transistor, and the preparation method of the low temperature polysilicon thin film transistor is as follows:

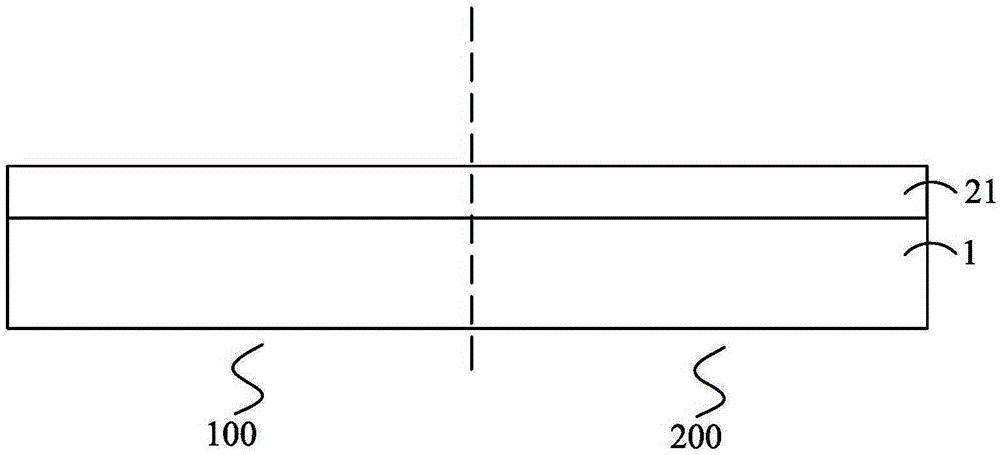

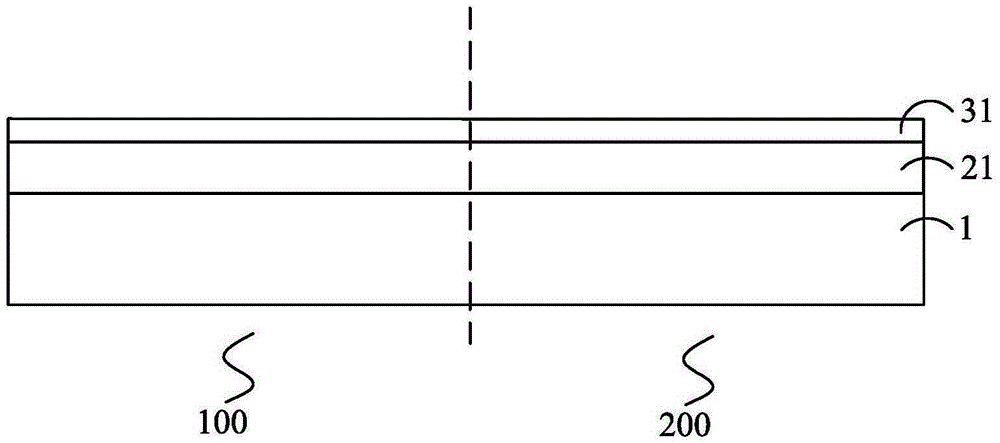

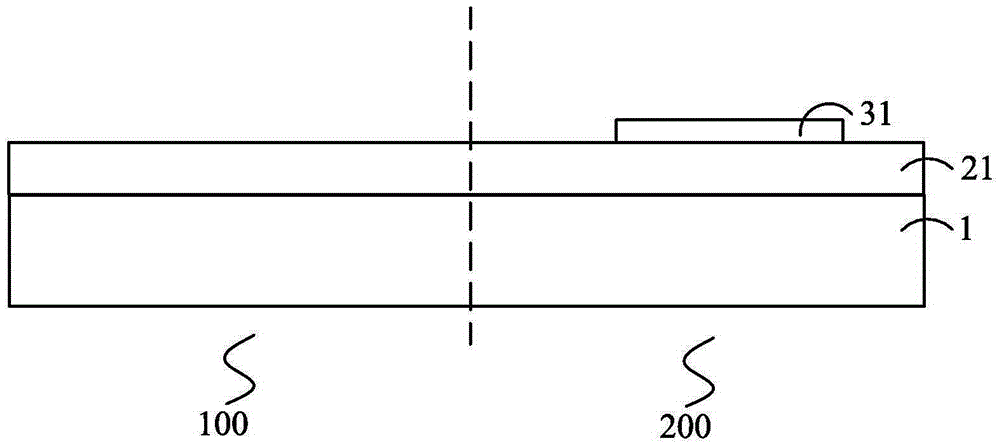

[0057] like figure 1 As shown, a glass substrate 1 is provided, and the glass substrate 1 includes a pixel area 100 on the left side and a peripheral driving area 200 on the right side. A pixel thin film transistor is formed in the pixel area 100 , and a driving thin film transistor as a driving unit is formed in the peripheral driving area 200 . Use chemical vapor deposition (CVD, Chemical VaporDeposition) method to form first buffer layer 21 on glass substrate 1, this first buffer layer is silicon nitride layer; Then, as figure 2 As shown, a metal molybdenum layer 31 is deposited and formed on the first buffer layer 21 as a reflective layer by using a chemical vapor deposition method, and a pho...

Embodiment 2

[0065] This embodiment provides a low temperature polysilicon thin film transistor, the thin film transistor includes a pixel thin film transistor and a driving thin film transistor, and the preparation method of the low temperature polysilicon thin film transistor is as follows:

[0066] like Figure 12 As shown, a glass substrate 1 is provided, and the glass substrate 1 includes a pixel area 100 on the left side and a peripheral driving area 200 on the right side. A pixel thin film transistor is formed in the pixel area 100 , and a driving thin film transistor as a driving unit is formed in the peripheral driving area 200 . A first buffer layer 21 and a second buffer layer 22 are sequentially deposited on the glass substrate 1 using a chemical vapor deposition method, the first buffer layer is a silicon nitride layer, and the second buffer layer is a silicon dioxide layer; then, as Figure 13 As shown, an aluminum oxide layer 32 is deposited and formed on the second buffer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com