Processing technology of PBT (Polybutylene Terephthalate) blue color masterbatch

A processing technology and color masterbatch technology, which is applied in the field of plastic processing, can solve the problems of affecting the identification effect of optical fiber and cable, affecting the linear expansion coefficient, and the decline of color gray scale, so as to overcome the linear expansion coefficient, speed up the crystallization time, and promote molding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

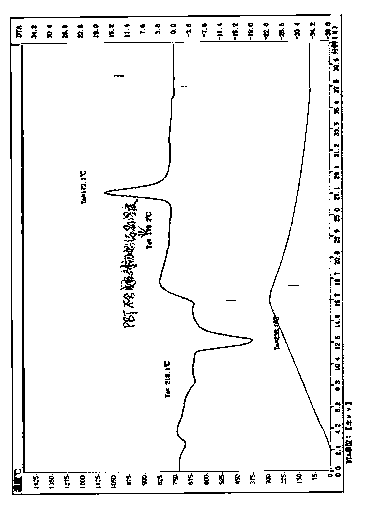

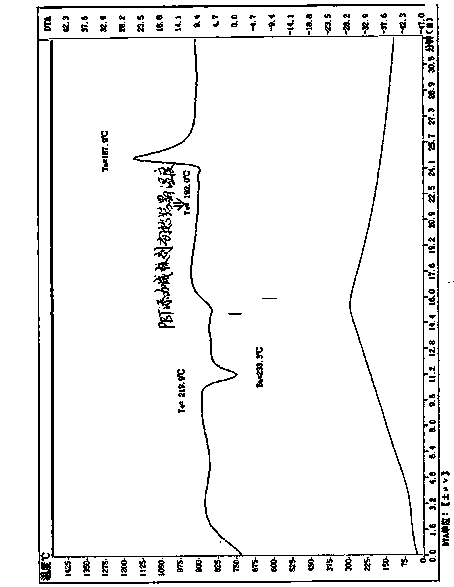

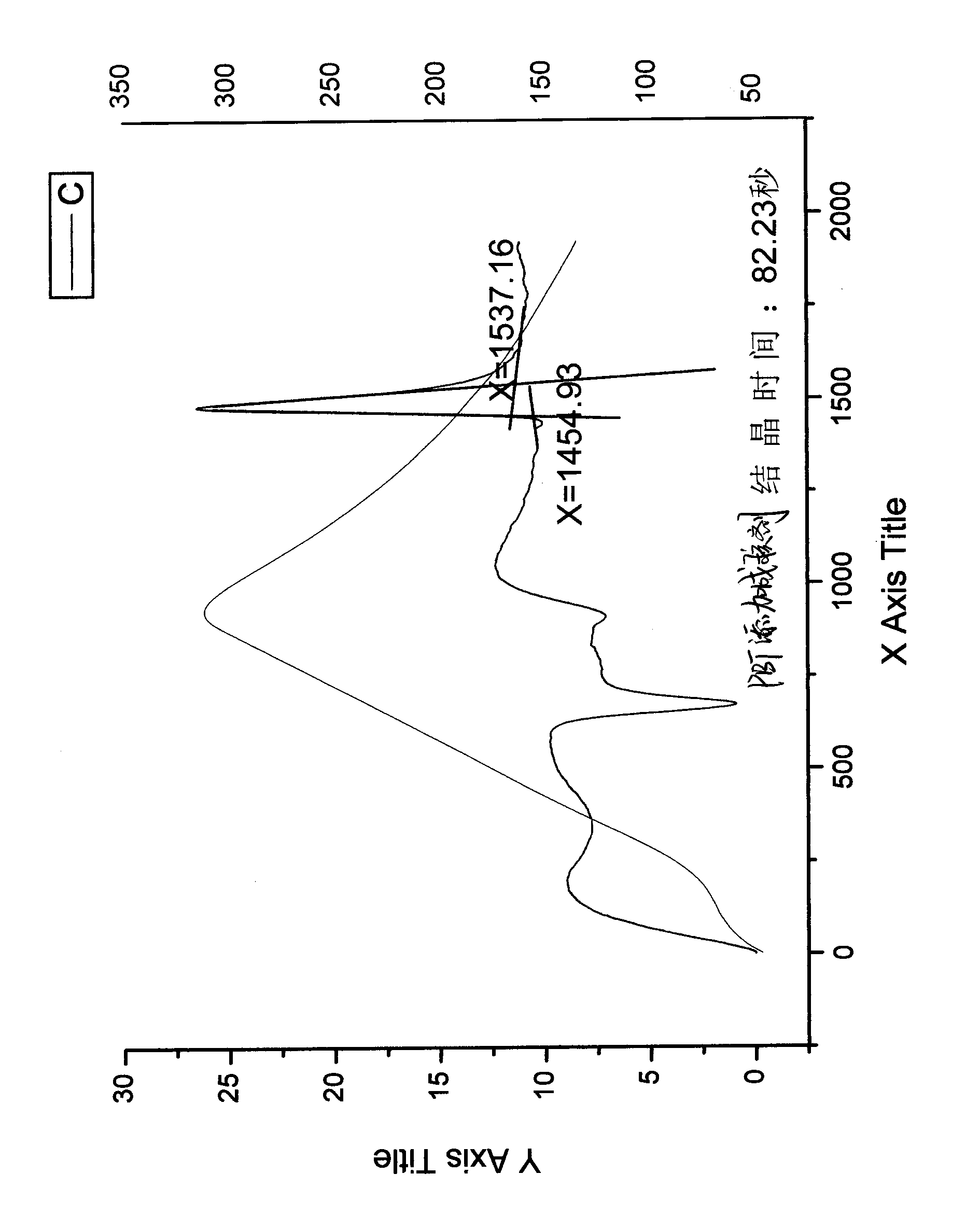

Method used

Image

Examples

Embodiment 1

[0017] In the present invention, when PBT and blue pigment are mixed and mixed, 0.5‰ of polypropylene nucleating agent and 0.5‰ of PVC heat stabilizer are added, and then kneaded.

[0018] During mixing, control the speed of the extruder so that the motor speed is controlled at 35 rpm, and the length-to-diameter ratio of the extruder screw is 35:1.

[0019] During mixing, the temperature in zones 1 to 6 is controlled at 200°C when the extruder is working.

Embodiment 2

[0021] In the present invention, when PBT and blue pigment are mixed and mixed, 2‰ of polypropylene nucleating agent and 2‰ of PVC heat stabilizer are added, and then kneaded.

[0022] During mixing, control the speed of the extruder so that the speed of the motor is controlled at 25 rpm, and the length-to-diameter ratio of the extruder screw is 35:1.

[0023] During mixing, the temperature in zones 1 to 6 is controlled at 260°C when the extruder is working. .

Embodiment 3

[0025] In the present invention, when mixing and mixing PBT and blue pigments, a polypropylene nucleating agent with a total weight of 1.5‰ and a PVC heat stabilizer with a total weight of 1.52‰ are added, and then kneaded.

[0026] During mixing, control the speed of the extruder so that the speed of the motor is controlled at 30 rpm, and the length-to-diameter ratio of the extruder screw is 35:1.

[0027] During mixing, the temperature in zones 1 to 6 is controlled at 230°C when the extruder is working.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com