Automatic dehumidification power transformation box

A transformer box, automatic technology, applied in the field of transformer box, can solve the problem that the air humidity of the transformer box cannot be changed automatically, and achieve the effect of prolonging the temperature rise time, increasing the sensitivity, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

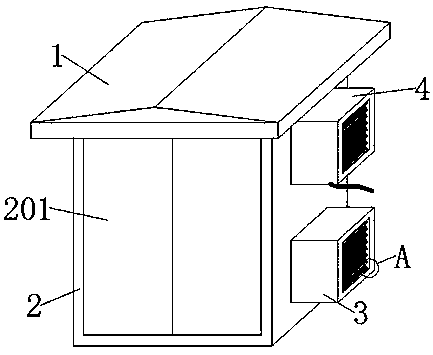

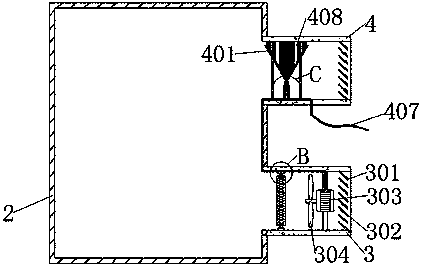

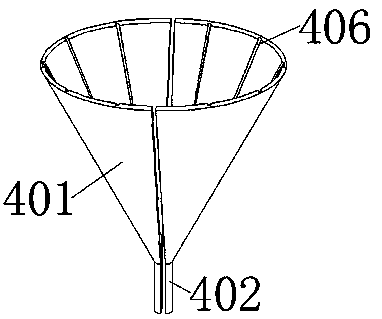

[0032] see Figures 1 to 11Among them, in the embodiment of the present invention, an automatic dehumidification transformer box includes a top plate 1, a dehumidification cylinder 3, a control cylinder 4 and a box body 2. The top plate 1 is welded on the top of the box body 2, and the right side of the box body 2 is embedded The dehumidification cylinder 3 and the control cylinder 4 are welded, and the dehumidification cylinder 3 is located directly above the control cylinder 4, and the front surface of the box body 2 is hinged with two cabinet doors 201; the dehumidification cylinder 3 includes an inclined plate 301, a vertical plate 302, Electric motor 303, fan blade 304, insulating seat 305, heat insulation rod 306, heat insulation conductive rod 307 and electric heating pipe 308, the right side of the inner wall of dehumidification cylinder 3 and the right side of the inner wall of control cylinder 4 are all welded with eight inclined plates 301 The right side of the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com