Liquid nitrogen inner-spraying type digital control milling and drilling machine gas adjusting system

A gas adjustment, drilling and milling machine technology, applied in the direction of boring/drilling, drilling/drilling equipment, maintenance and safety accessories, etc., can solve the personal safety hazards of machine tool operators, reduce machining accuracy and production efficiency, and affect the spindle Tool clamping operation and other problems, to achieve the effect of reducing water vapor content, reducing frost, and preventing nitrogen poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

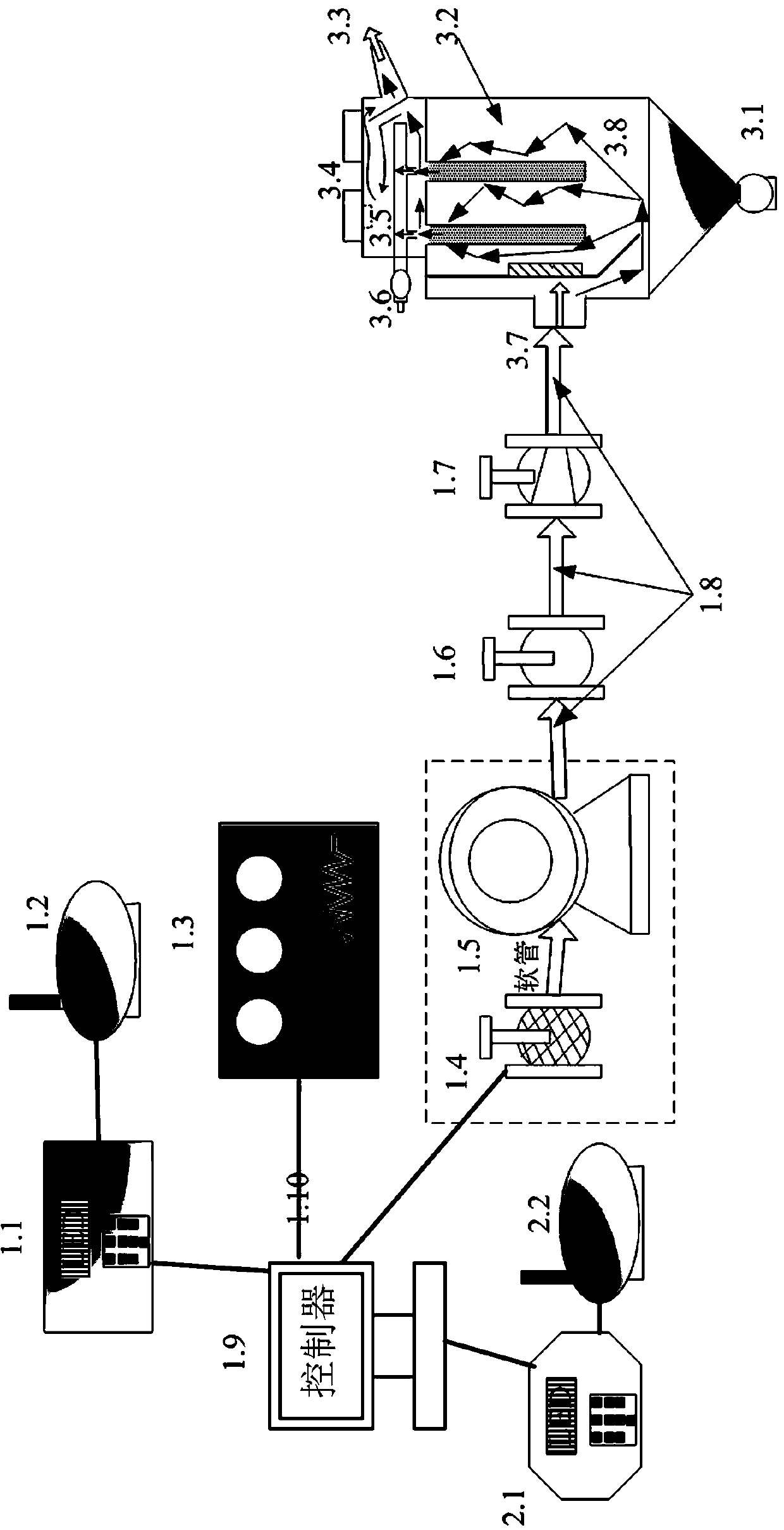

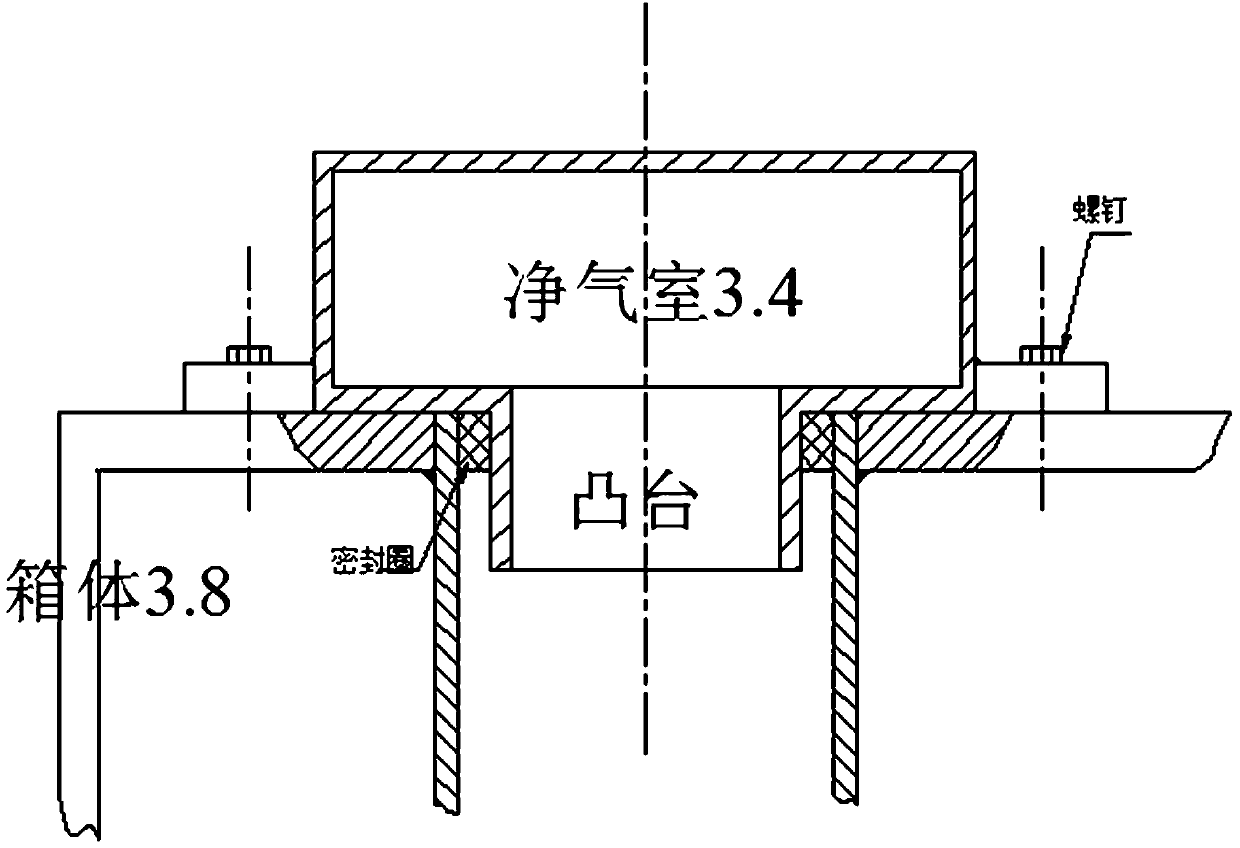

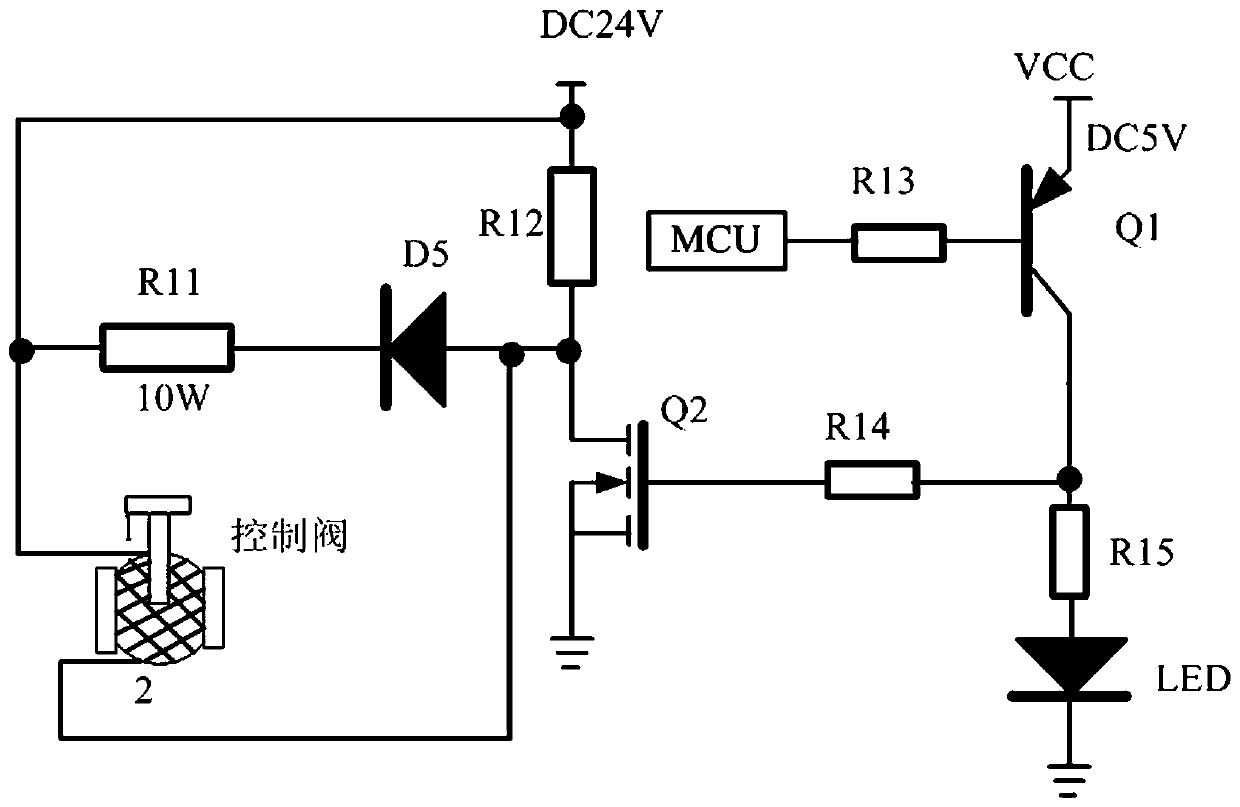

[0032] As shown in the figure, the present invention includes a humidity tester inside the drilling and milling machine warehouse, a nitrogen concentration monitor inside the drilling and milling machine warehouse, a dryer inside the drilling and milling machine warehouse, a controller, an exhaust fan, a straight discharge control valve, a flow rate control valve, and a dust removal mechanism. The alarm signal output port of the tester is connected to the alarm signal input port of the humidity alarm, and the alarm signal output port of the nitrogen concentration monitor is connected to the alarm signal input port of the nitrogen concentration alarm;

[0033] The filter valve is set on the top of the drilling and milling machine chamber, the inlet port of the filter valve is connected with the interior of the drilling and milling machine chamber, the outlet port of the filter valve is connected with the inlet port of the exhaust fan through a pipe, and the outlet end of the exha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com