Patents

Literature

48results about How to "Rapid liquefaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

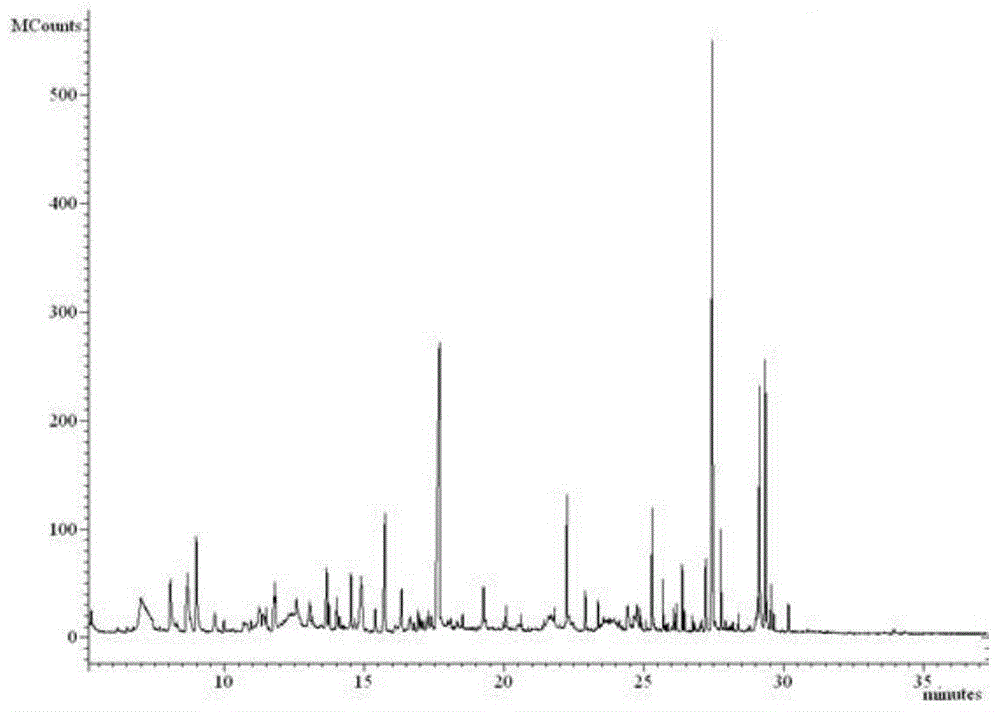

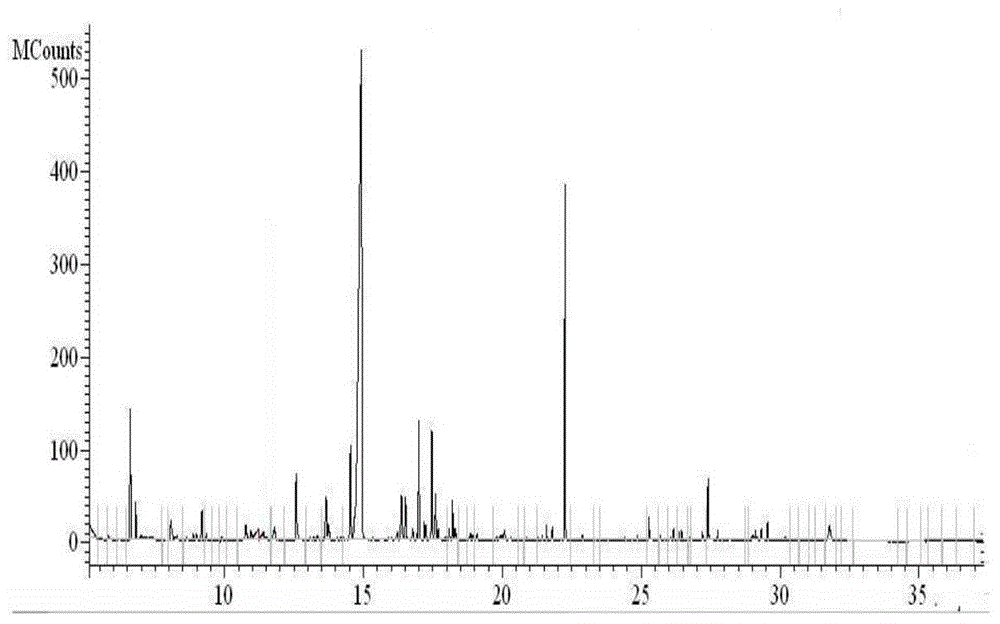

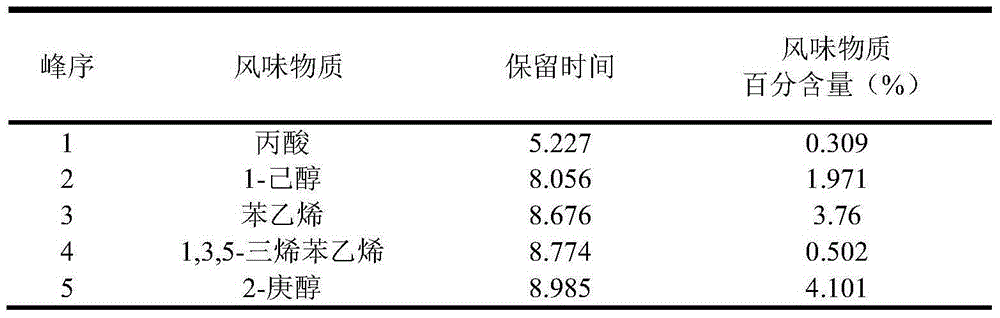

Modern big-pot brewing method of duck-blood glutinous rice and gingko low-alcohol yellow rice wine

ActiveCN105087280AFunction increaseIncrease biological functionAlcoholic beverage preparationGinkgolideAlpha-amylase

The invention discloses a modern big-pot brewing method of duck-blood glutinous rice and gingko low-alcohol yellow rice wine, and belongs to the technical field of food processing. The modern big-pot brewing method comprises the following steps: polished round-grained rice is taken as the base stock, and mixed with duck-blood glutinous rice and gingko, so that the contents of such active substances as biochrome and ginkgolides in the final yellow rice wine product can be improved; high-temperature alpha-amylase and saccharifying enzyme are respectively adopted for two-step enzymolysis; the raw materials subjected to enzymatic saccharification are mixed with a saccharomyces cerevisiae Chinese yeast for fermentation; after main fermentation, Galactomyces geotrichum KG-1 is added for further fermentation and low-temperature maturation; squeezing, filtering clarification, sterilization and filling are performed to obtain the duck-blood glutinous rice and gingko low-alcohol yellow rice wine. The modern big-pot brewing method for the duck-blood glutinous rice and gingko low-alcohol yellow rice wine has the benefits that as the raw-material high-temperature enzymolysis soaking process is adopted, the processing time is remarkably shortened; as Galactomyces geotrichum KG-1 participates in fermentation of the yellow rice wine, the product alcoholic strength is low, the taste is mellow and refreshing, and the health-care function is enhanced.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

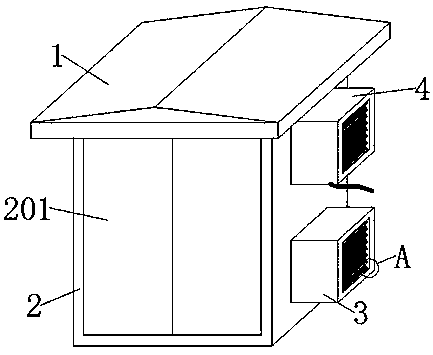

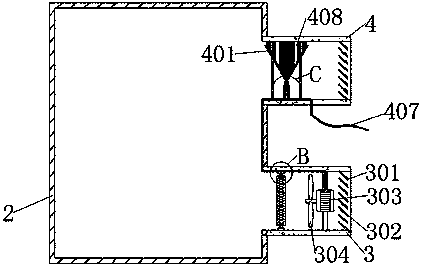

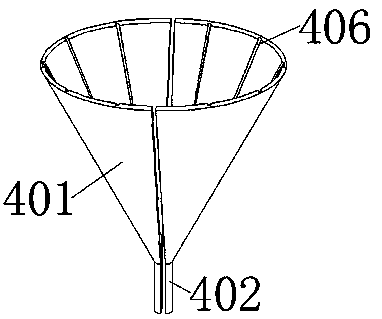

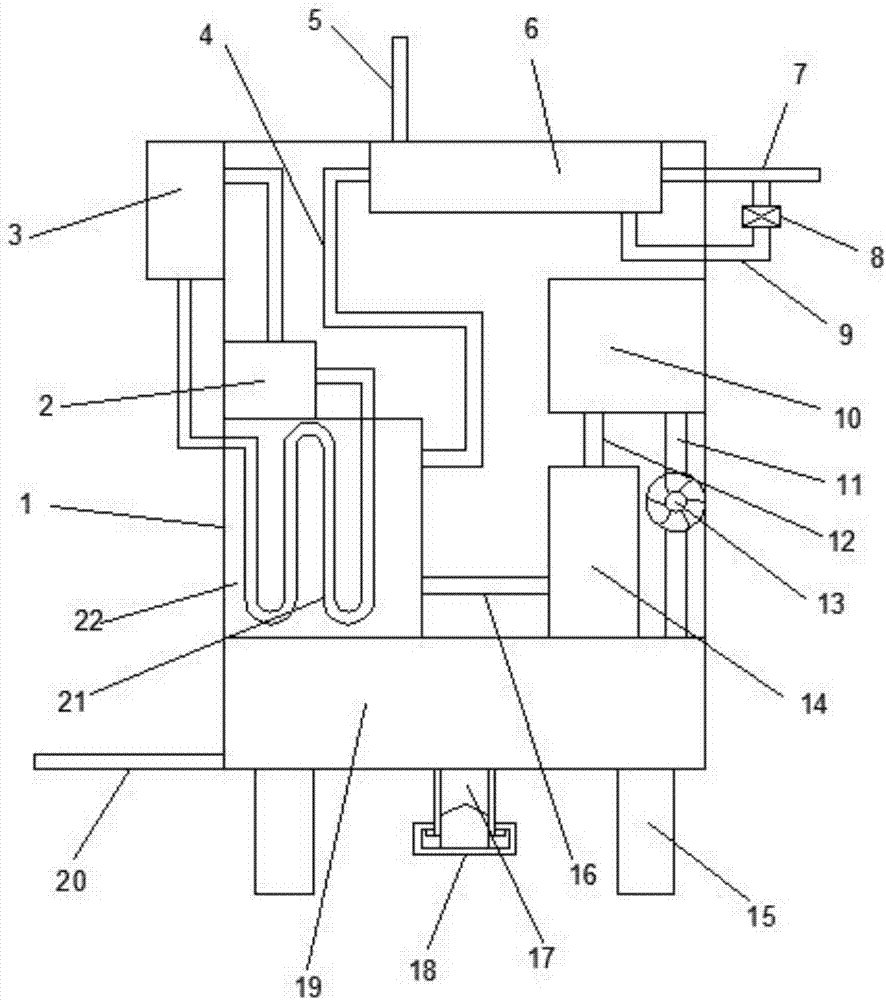

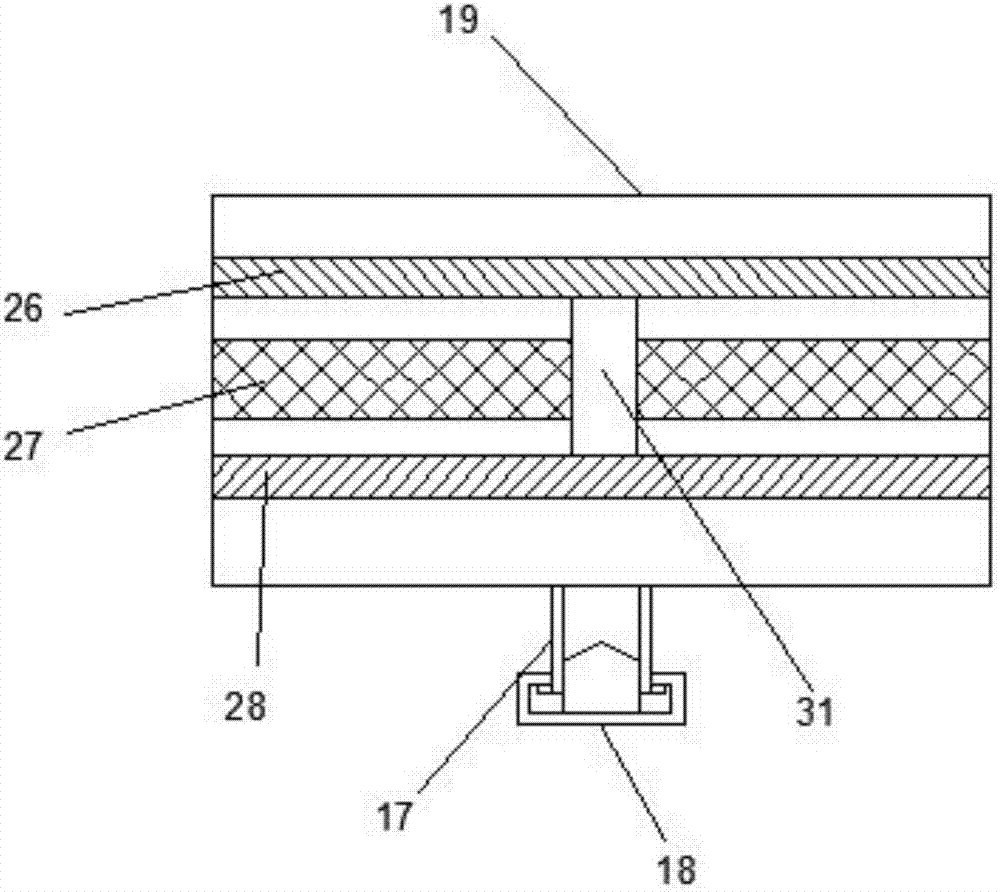

Automatic dehumidification power transformation box

ActiveCN109713587AReduce air humidityAutomatic dehumidification realizedSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsMotor driveEngineering

The invention provides an automatic dehumidification power transformation box, which comprises a top plate, a dehumidification cylinder, a control cylinder and a box body. The top plate is welded to the top of the box body. The dehumidification cylinder and the control cylinder are welded to the right side of the box body in an embedded mode. The dehumidification cylinder is located right over thecontrol cylinder. Two cabinet doors are hinged to the front surface of the box body through hinges. According to the invention, when the air humidity in the box body is increased, the heat of the aqueous vapor can be quickly absorbed by metal water collecting barrels when the aqueous vapor gets in contact with the metal water collecting barrel. Therefore, the aqueous vapor in the metal water collecting barrels can be quickly liquefied on the inner wall of the metal water collecting barrels to form water drops. After the water drops are accumulated to a certain extent, the water drops flow down along the inner wall of the metal water collecting barrel and flow towards water running plates. When water on the water running plates comes up together, the two water running plates can form a current loop. In this way, a power supply for a motor and an electric heating pipe is switched on by an electric wire. The electric heating pipe starts heating to dry the air. The motor drives fan bladesto rotate to form the airflow and the airflow is driven to blow into the box body. The air humidity in the box body is reduced, and the automatic dehumidification is achieved.

Owner:源洲电气有限公司

Method for preparing biodegradable polyurethane rigid foam from bamboo waste liquefaction products

InactiveCN101362818BRealize the purpose of turning waste into treasureReduce dependencePolymer sciencePolyethylene glycol

The invention discloses a method for preparing biodegradable rigid polyurethane foam with liquefaction products of bamboo waste, which comprises the following steps: 1 mass portion of crude glycerin / polyethylene glycol liquefying solvent and 0.02-0.04 mass portion of concentrated sulfuric acid are added into a reaction vessel, heated till the temperature reaches 120-180 DEG C after a reflux condensation tube is connected to the reaction vessel; 0.2-0.5 mass portion of crushed and dried bamboo waste is added, reacted for 90-180min with stirring, taken out and cooled and neutralized by MgO tillbeing neutral; 1 mass portion of liquefaction products of bamboo waste, 0.02-0.08 portion of a dibutyl tin dilaurate / triethylene diamine mixed catalyst, 0.02-0.06 portion of silicone oil, 0.02-0.1 portion of water and 0.1-0.15 portion of fire retardant are added into a container, premixed for 20-30s when stirred at 2,000r / min, added with sufficient PAPI with the molar ratio between isocyanato-NCOin PAPI and hydroxyl group-OH in bamboo waste liquefaction products being 0.6-1.2, stirred for 10s-15s at 1,000r / min, put into a mould, foamed with standing at room temperature, placed for slaking and mould separating at room temperature for 24h-72h after reaction. The method fully utilizes resources, reduces liquefaction cost, and has a mild reaction temperature and stable liquefaction products;the performance of obtained foam meets the national standard and biodegradability.

Owner:NANCHANG UNIV

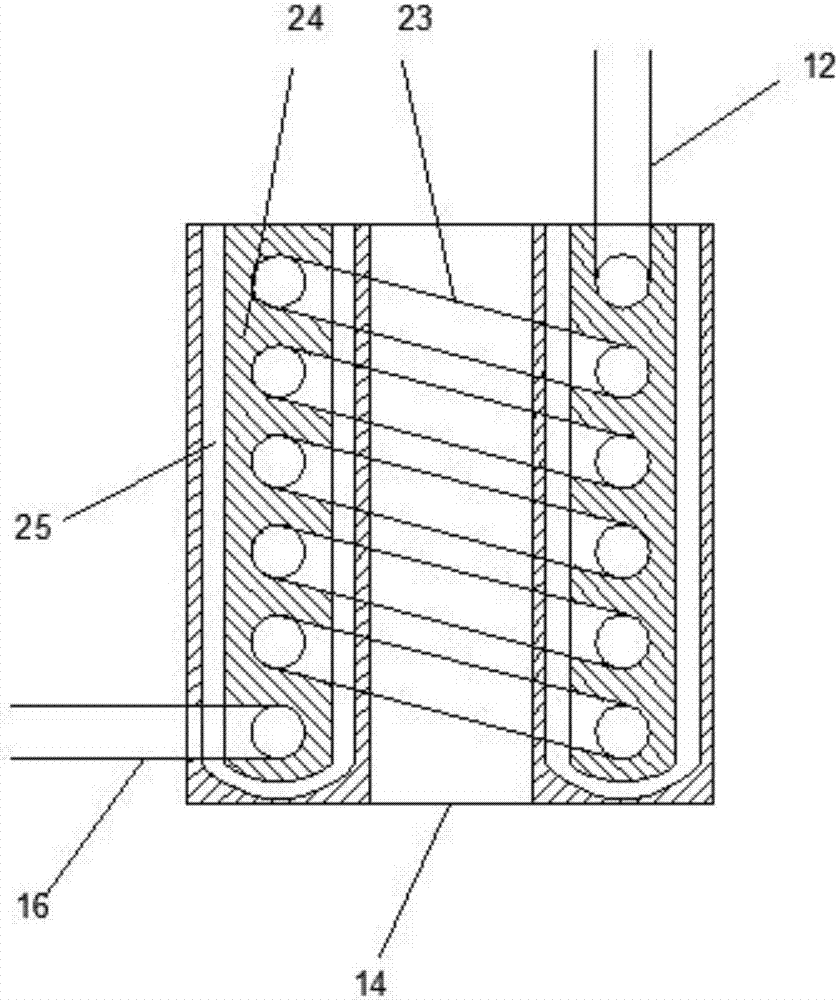

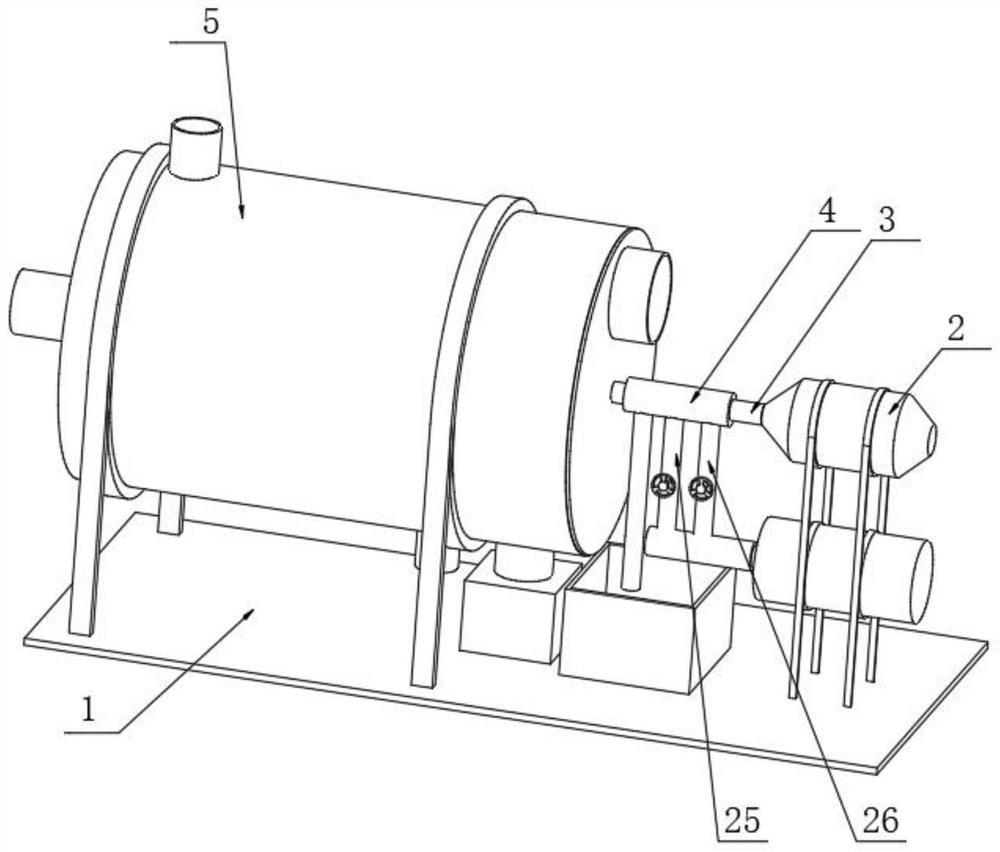

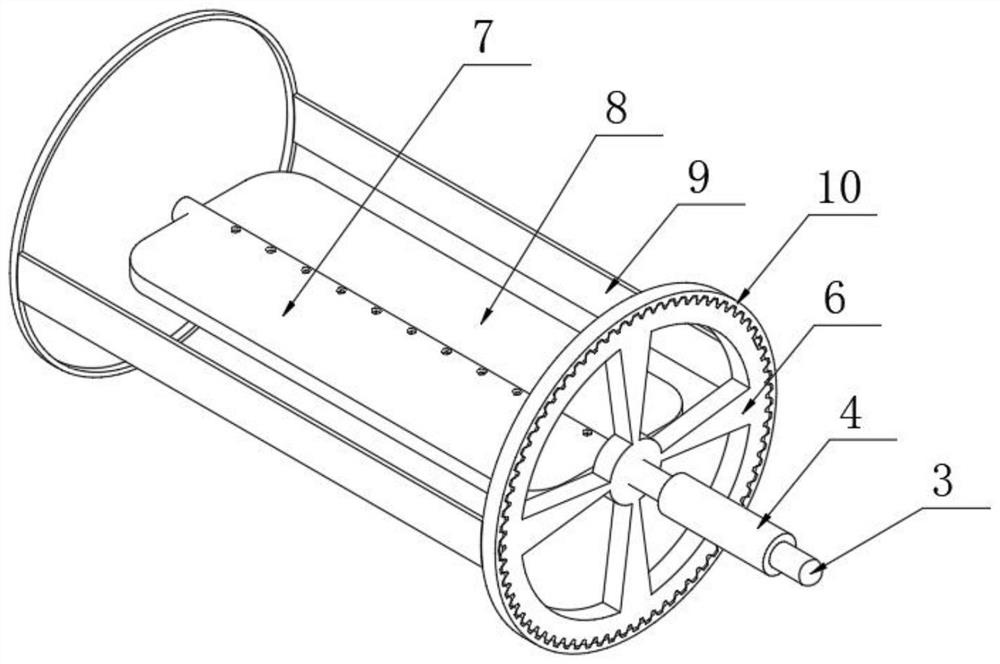

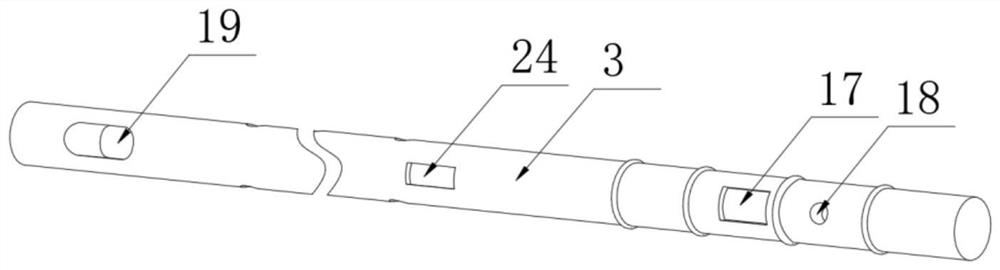

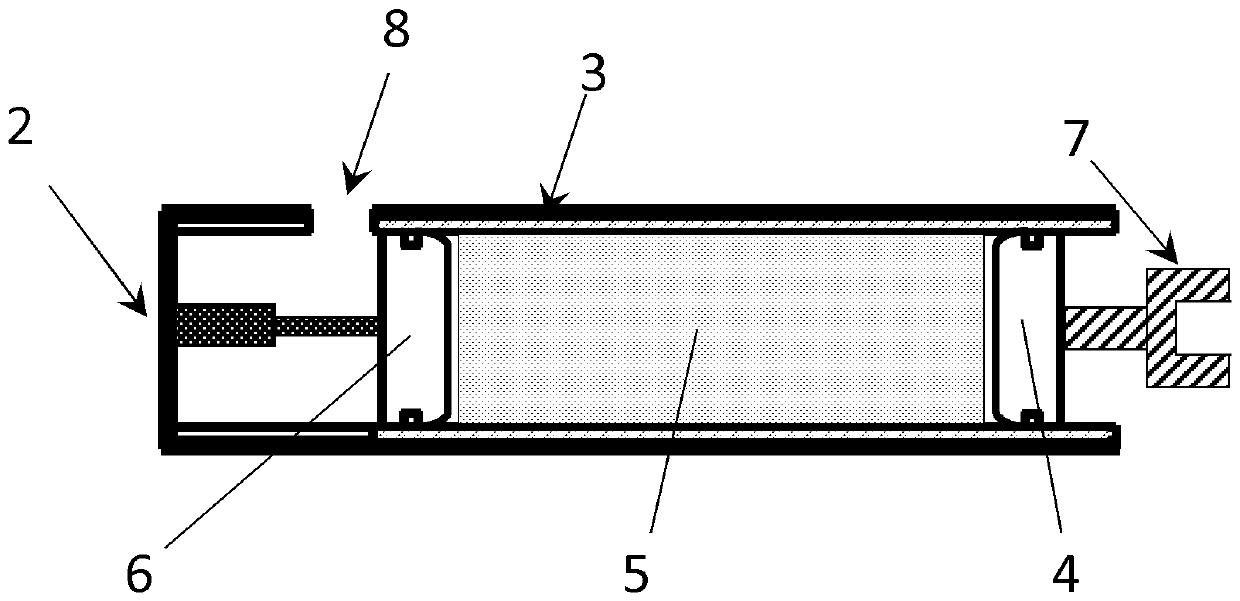

Quenching device for aluminum alloy circular pipe

ActiveCN109680229AReduce the chance of deformation and fractureReduce frictionFurnace typesHeat treatment furnacesCooling chamberWater spray

The invention belongs to the technical field of aluminum alloy production equipment and particularly provides a quenching device for an aluminum alloy circular pipe. The quenching device comprises a solid dissolving chamber and a cooling chamber. A partition plate is arranged between the solid dissolving chamber and the cooling chamber. Multiple heating devices are arranged in the solid dissolvingchamber. Multiple water spraying devices are arranged in the cooling chamber. A roller cylinder is arranged on the inner wall of the cooling chamber and penetrates through the water spraying devices.According to the quenching device, by arranging the water spraying devices, the multiple water spraying devices in the horizontal direction can achieve multi-station quenching, quenching efficiency is high, when all the stations work, the water spraying devices on the adjacent stations are arranged in a staggered manner, the water spraying devices above and below can spray water to the dead angleportion between the two adjacent water spraying devices on a current supporting pipe, uniformity is good, the probability of deformation and breakage of the circular pipe due to uneven stress causedby heat expansion and cold shrinkage of metal is reduced, meanwhile, the water spraying devices can be folded upwards before spraying water, the tops of the water spraying devices can be stretched after cooling the circular pipe, the circular pipe can be taken out upwards conveniently, and friction between the circular pipe and the roller cylinder is reduced.

Owner:佛山市八斗铝业有限公司

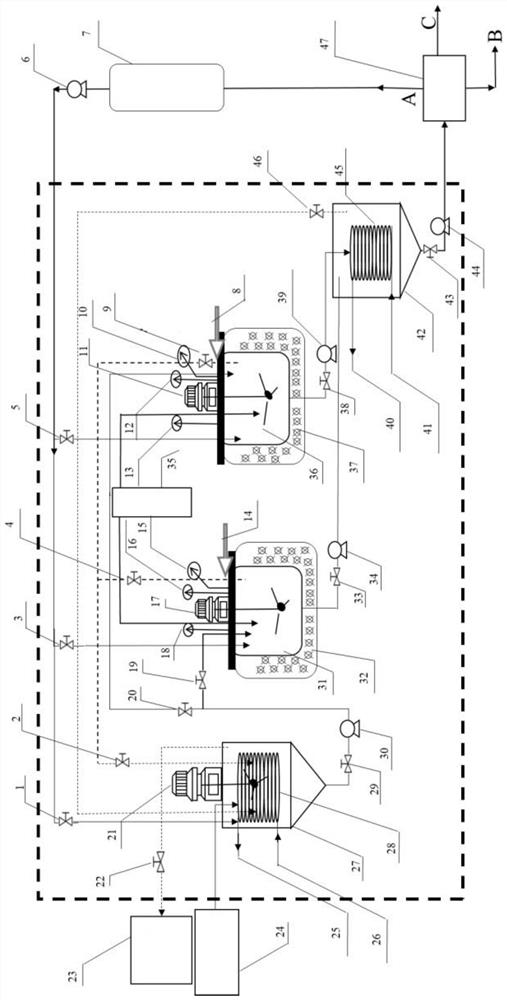

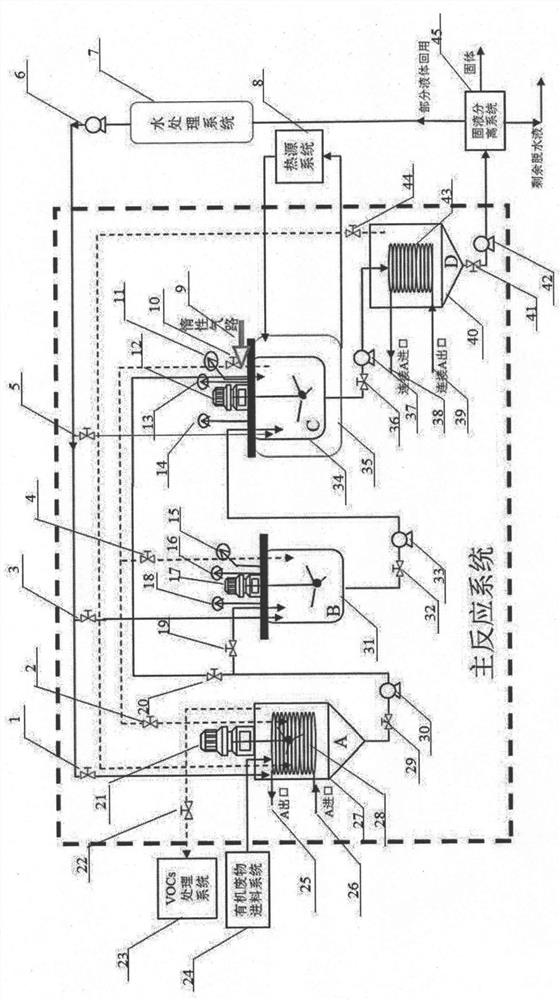

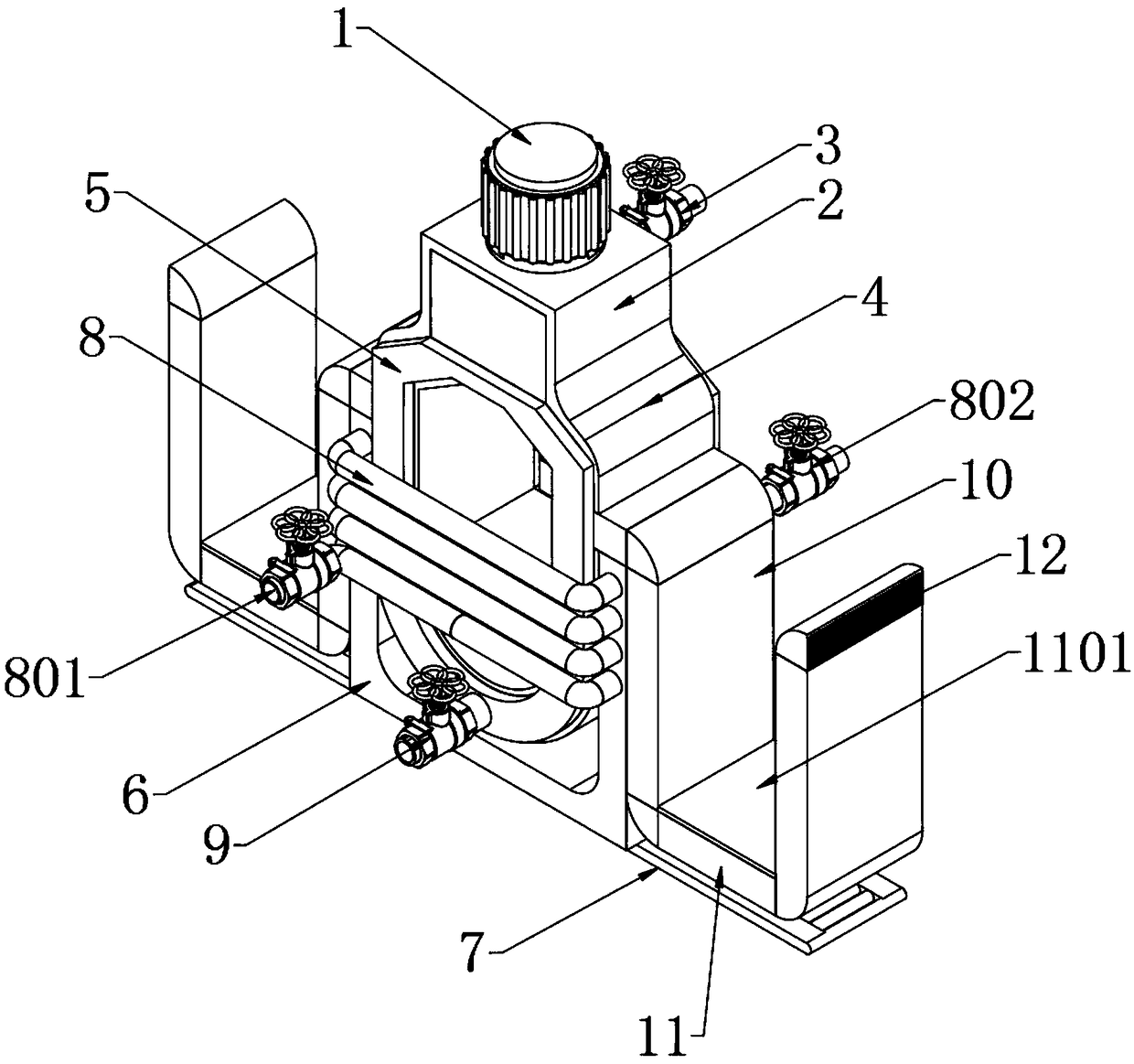

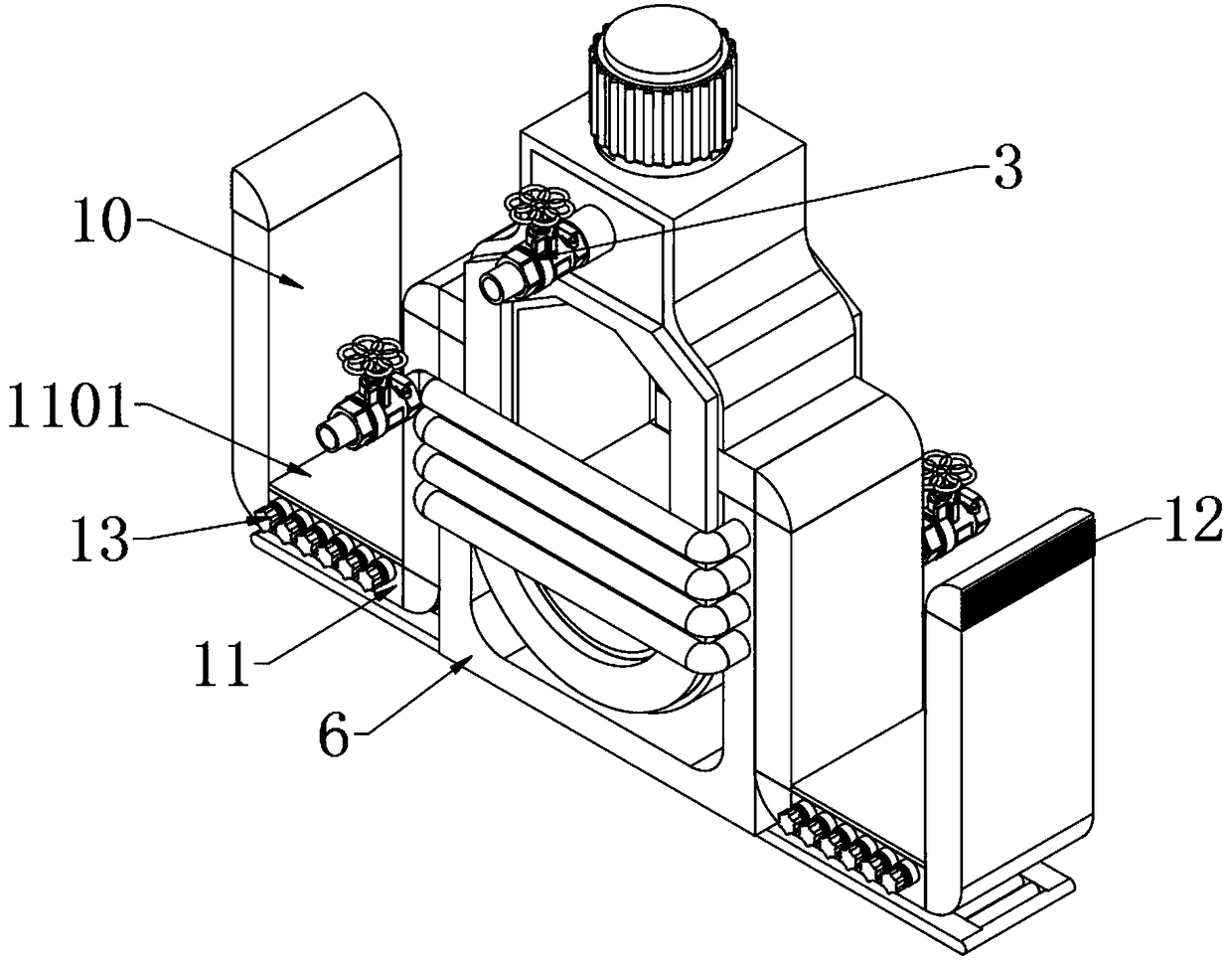

Device for achieving thermocatalytic efficient reduction and reclamation of organic wastes

ActiveCN107445424AAchieve efficient weight reductionImplement resourcesSludge treatmentDispersed particle separationWater treatment systemSource system

The invention provides a device for achieving thermocatalytic efficient reduction and reclamation of organic wastes. An organic waste feeding system is connected to a proportioning kettle material inlet, the proportioning kettle material outlet is connected to a pre-reaction kettle and the material inlet of a primary reaction kettle, the material outlet of the pre-reaction kettle is connected to the material inlet of the primary reaction kettle, the material outlet of the primary reaction kettle is connected to the material inlet of a cooling kettle, and the material outlet of the cooling kettle is connected to a solid-liquid separation system; a part liquid outlet of the solid-liquid separation system is connected to a water treatment system, and the liquid outlet of the water treatment system is separately connected to the proportioning kettle, the pre-reaction kettle and the material inlet of the primary reaction kettle; a jacket of the primary reaction kettle is connected to a heat source system; the steam outlet of the primary reaction kettle is connected to the proportioning kettle and the steam inlet of the pre-reaction kettle, and the steam outlet of the cooling kettle is connected to the steam outlet of the proportioning kettle; and the cooling water inlet and outlet of the proportioning kettle are connected to the cooling water outlet and inlet of the cooling kettle. The reduction effect of the organic waste is good, a catalyst can be recycled, and the solid product after reaction can be recycled.

Owner:DONGHUA UNIV

Starch liquefaction and saccharification technology in fructose production

The invention discloses a starch liquefaction and saccharification process based on the production of fructose. The starch is prepared with water to make starch milk with a dry matter content of 30%-35%, the pH is adjusted to 6.0-6.5 with hydrochloric acid, and ɑ- is added to each ton of starch raw material. The amount of amylase is 6-10μ / g starch, adding CaCl2 to adjust the Ca" concentration to 0.01mol / l, the slurry is pumped into the jet liquefier, the temperature is raised to 105-110°C instantaneously, the pipeline liquefaction reaction takes 10-15min, and the feed liquid is transported to the liquefaction tank, at 95-97°C, add ɑ-amylase twice, continue the liquefaction reaction for 40-60 minutes, and the iodine color reaction is qualified; the starch liquefaction solution is introduced into the saccharification tank, cooled to 60°C, adjusted to pH 4.5, and added 80μ / g starch glucoamylase, with intermittent stirring, keep warm at 60°C for 40-50h, saccharify to DE>95, heat to 90°C, destroy the glucoamylase and stop the saccharification reaction. This process can make the starch liquefy and saccharify quickly, The fructose produced has high quality and good taste and meets people's needs.

Owner:黄鸣

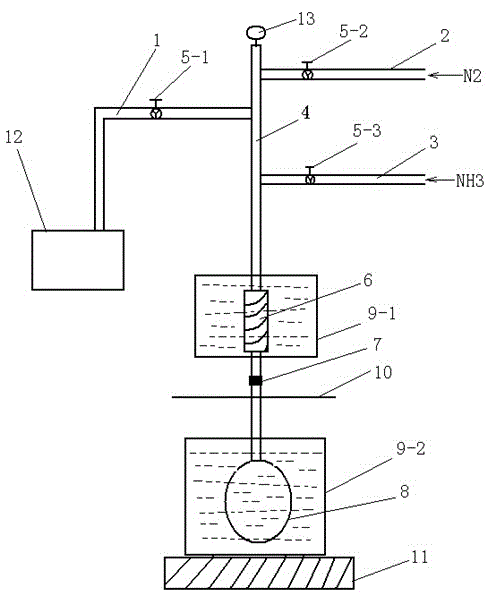

Preparation method of inorganic compound sodium selenide and device of preparation method

ActiveCN103818885AGuaranteed purityEnsure safetyBinary selenium/tellurium compoundsSodium selenideNitrogen gas

The invention discloses a preparation method of an inorganic compound sodium selenide and a device of the preparation method. The preparation method comprises the steps of: (1) putting metallic sodium and elemental selenium in a reactor in a vacuum glove box, (2) highly vacuumizing, charging nitrogen to, cleaning and highly vacuumizing the reactor repeatedly for 3-4 times, (3) charging liquid ammonia to allow metallic sodium to be completely dissolved in liquid ammonia, (4) discharging gasified ammonia from the reactor via high-purity nitrogen, (5) stirring, (6) after gasifying liquid ammonia, vacuumizing the reactor, and (7) heating the reactor, then cooling to the room temperature, and taking a material to obtain a sodium selenide finished product. According to the preparation method, metallic Na and elemental Se are isolated from air all the time from a proportioning stage to a combination reaction course, and the purity of raw materials and synthesized sodium selenide and the safety in a reaction course are effectively ensured. At the same time, the device realizes a complete preparation technical flow of sodium selenide synthesis, ammonia volatilization, in situ synthesized polycrystal drying and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Process for precooling, expanding and liquefying natural gas

InactiveCN103712415ARapid liquefactionReduce power consumptionSolidificationLiquefactionGas phaseMulti stream

The invention discloses a process for precooling, expanding and liquefying natural gas. The process includes (a), compressing nitrogen at two stages, then cooling the compressed nitrogen by the aid of coolers, and precooling the cooled compressed nitrogen in multi-stream heat exchangers; (b), expanding the nitrogen by the aid of turbo expanders and filling backflow to heat exchangers; (c), secondarily expanding the nitrogen by the aid of the turbo expanders and sequentially filling backflow to the heat exchangers; (d), compressing and pressurizing propane by the aid of propane compressors; (e), enabling the pressurized propane to flow through water coolers; (f), performing cooling and depressurization to generate a gas phase and a liquid phase, filling the gas phase and the liquid phase into the multi-stream heat exchangers and precooling the natural gas and high-pressure refrigerants by the aid of the multi-stream heat exchangers; (g), cooling the natural gas by the heat exchangers at first; (h), depressurizing and cooling the cooled natural gas by the aid of throttle valves to generate a gas phase, and storing the remaining liquid phase in liquefied natural gas storage tanks; (i), filling the gas phase as backflow gas into the heat exchangers to provide cooling capacity for the heat exchangers, reheating the backflow gas and using the reheated backflow gas as regenerated gas for purifiers for pre-treating the natural gas. The process has the advantages that the natural gas can be quickly liquefied, and power consumption and the cost are low.

Owner:吴林松

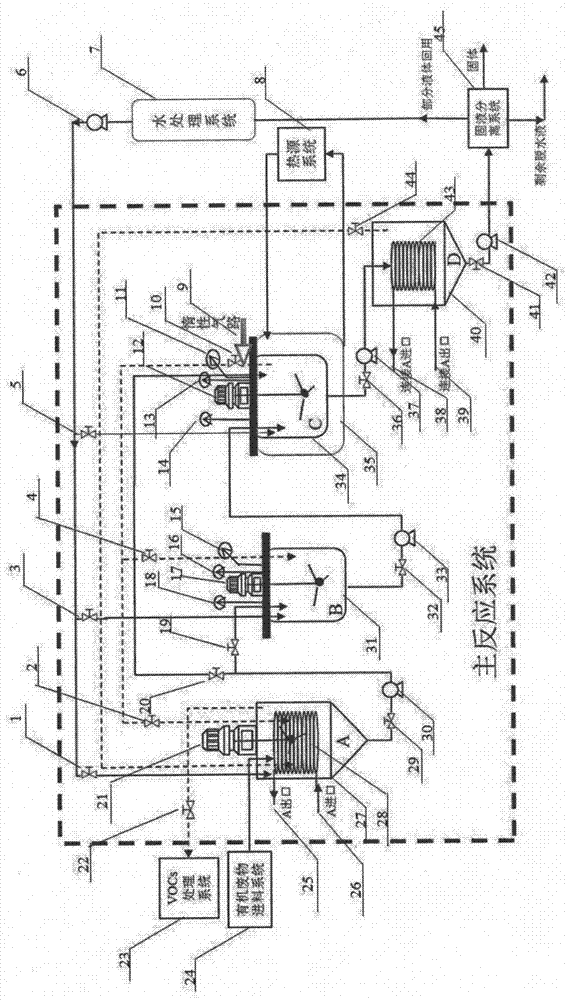

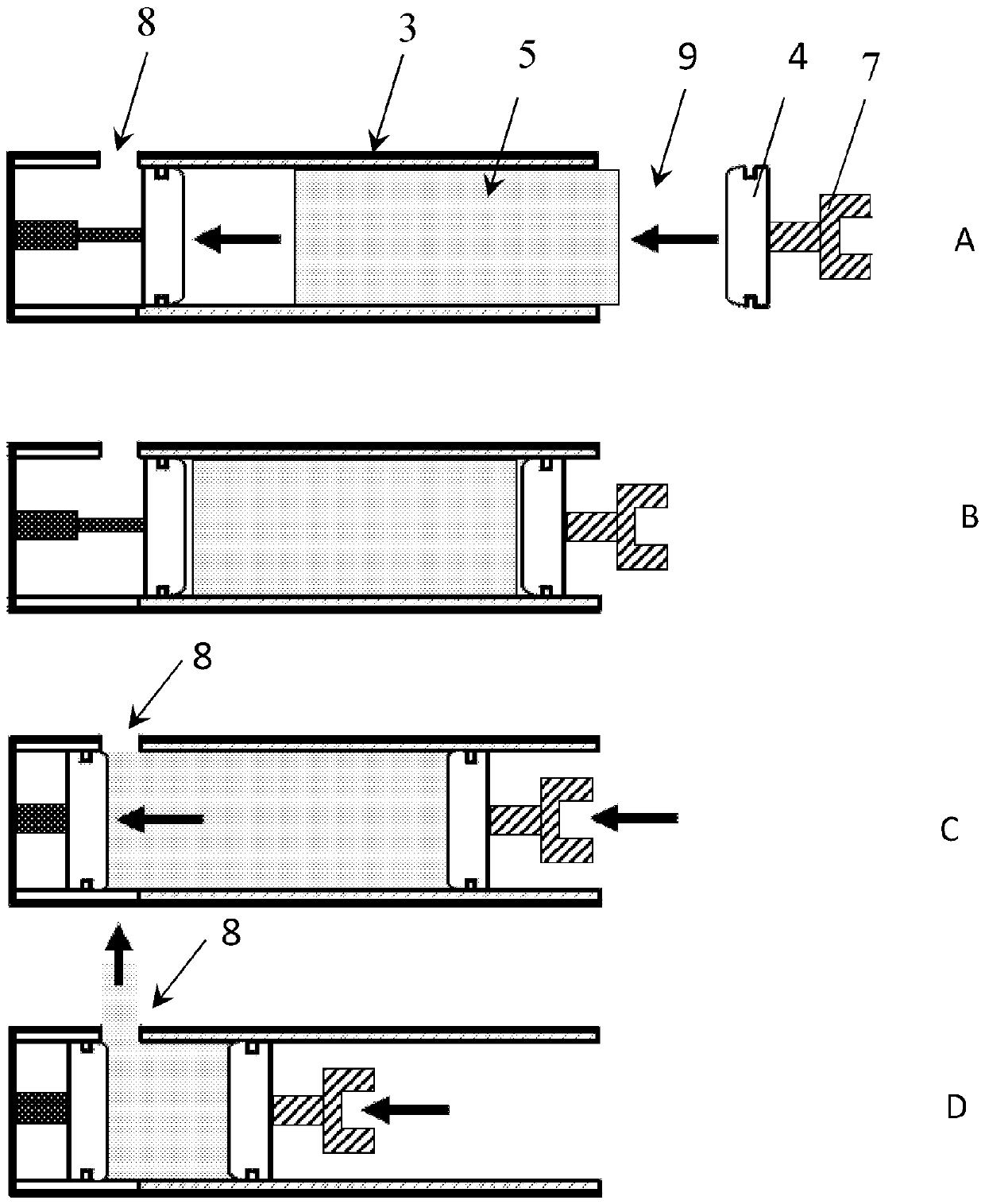

Organic hazardous waste thermocatalytic efficient reduction double-kettle process equipment

InactiveCN111644135ALow reaction temperatureDelayed reaction timeChemical/physical/physico-chemical stationary reactorsPtru catalystProcess equipment

The invention discloses organic hazardous waste thermocatalytic efficient reduction double-kettle process equipment. The equipment is characterized by comprising a batching kettle with a material inlet connected to an organic waste feeding system, the batching kettle is connected to a first main reaction kettle and a second main reaction kettle respectively, the first main reaction kettle and thesecond main reaction kettle are connected to a cooling kettle, and the cooling kettle is connected to a solid-liquid separation system; the first main reaction kettle and the second main reaction kettle are connected to a steam system; the first main reaction kettle is connected to the batching kettle and the second main reaction kettle; the second main reaction kettle is connected to the batchingkettle and the first main reaction kettle; the cooling kettle is connected to the batching kettle, and the batching kettle is connected to a VOCs treatment system; and a cooling water pipeline of thecooling kettle and the batching kettle are communicated to form a cooling water circulation system. Hot steam is recycled through flash evaporation between the double-kettle equipment, energy is greatly saved, a catalyst is recycled after water treatment, and use of the catalyst is reduced; and a carbon crystallization product obtained by the reaction can be recycled, so that secondary pollutionto the environment is avoided.

Owner:DONGHUA UNIV

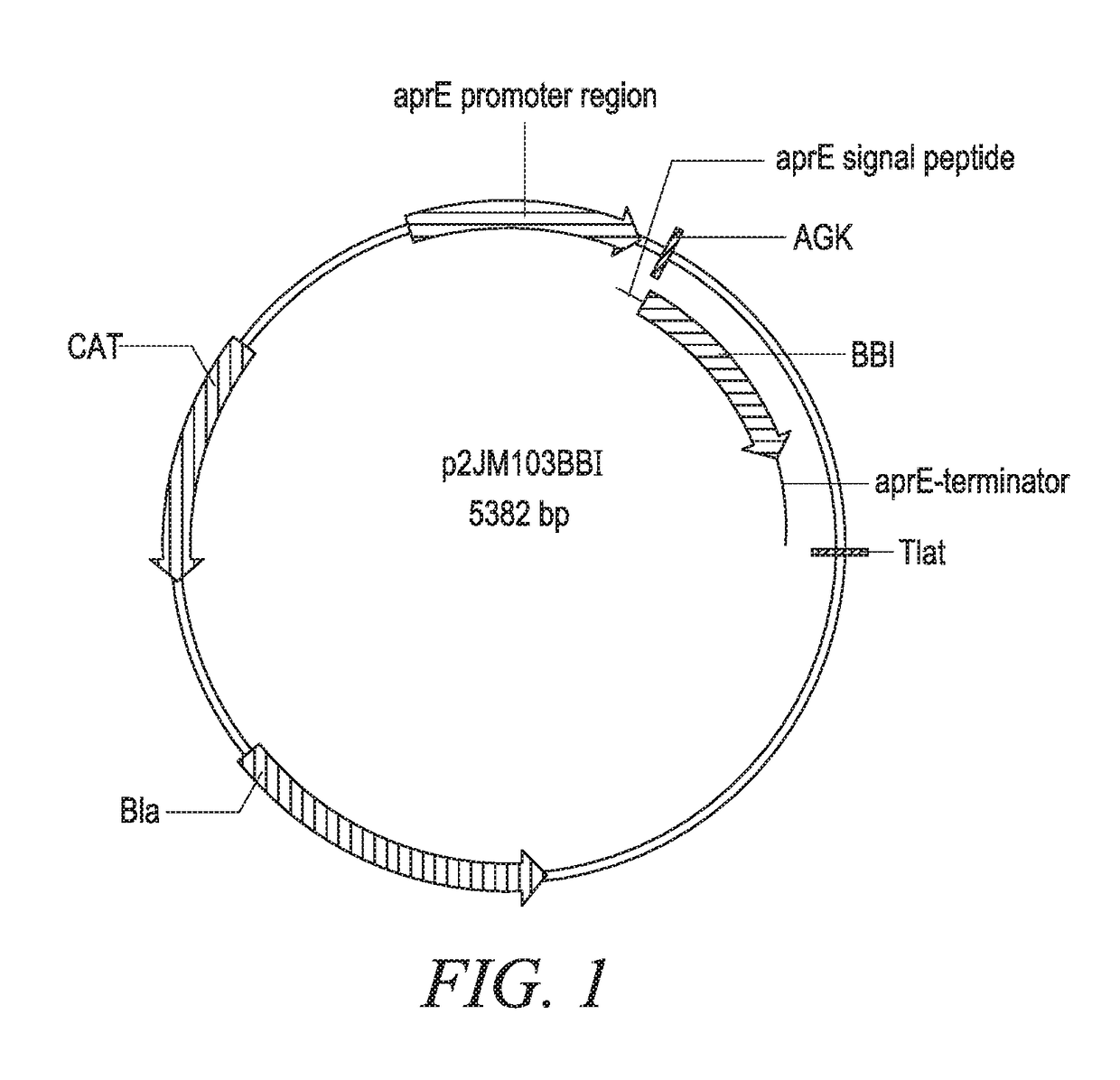

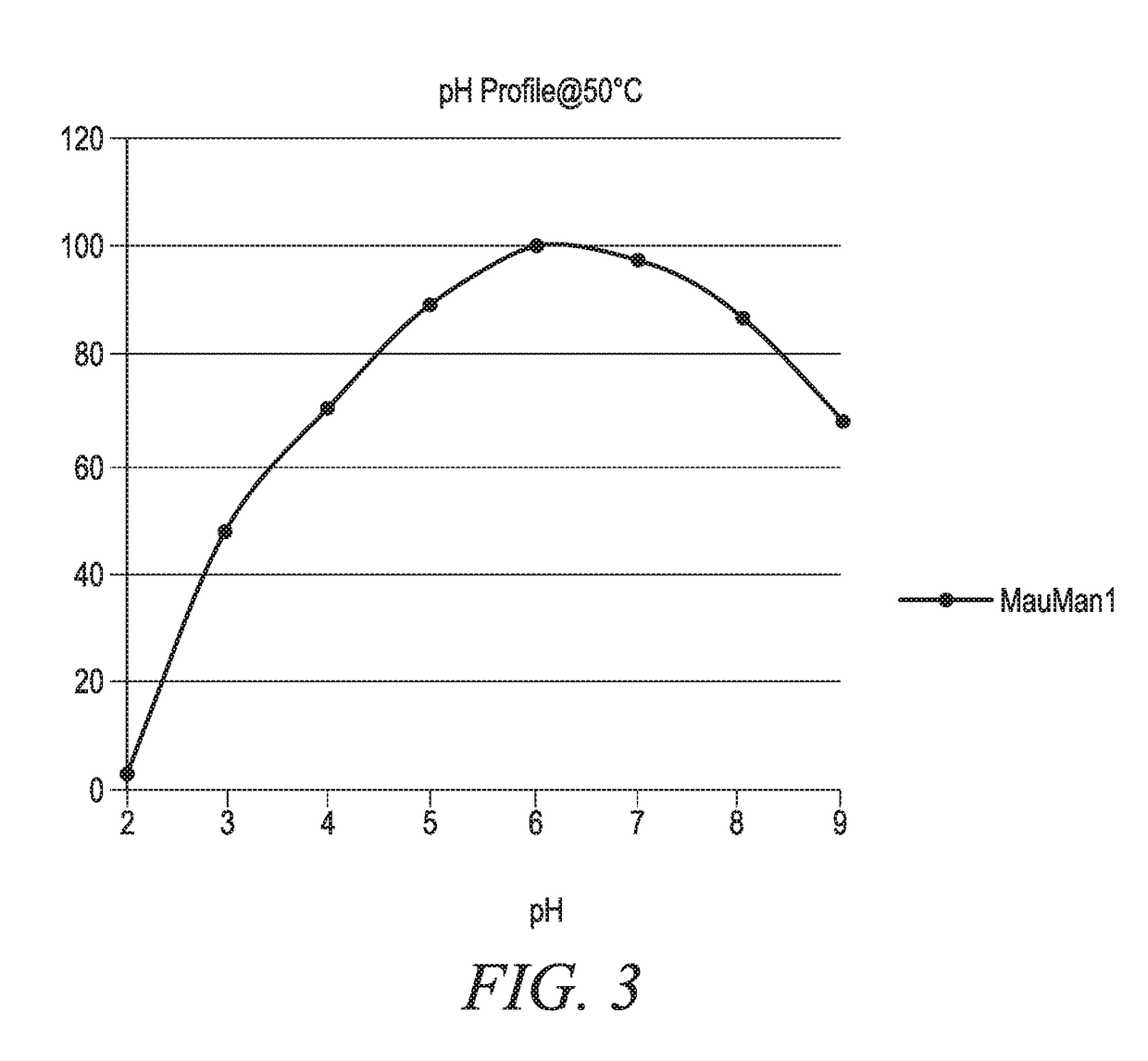

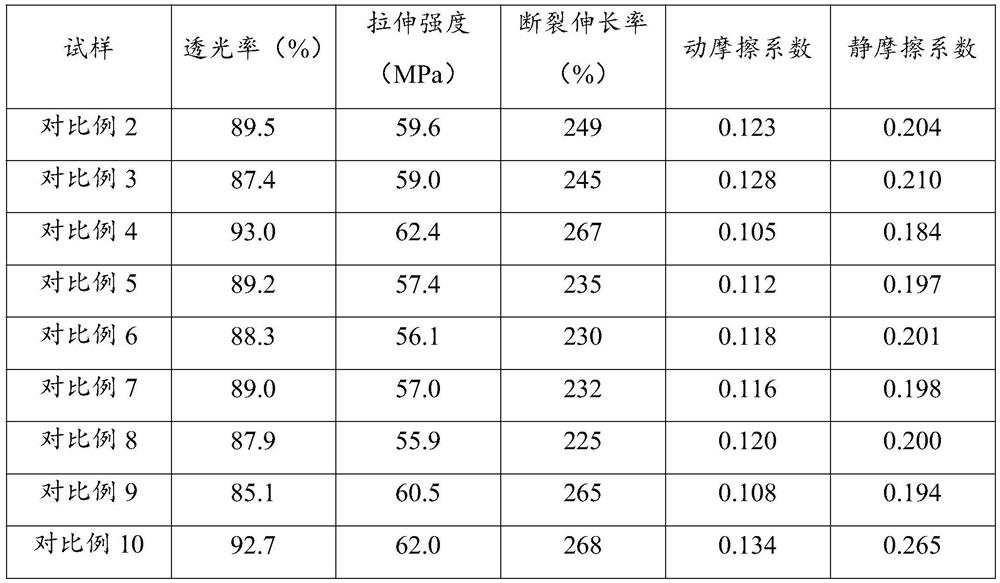

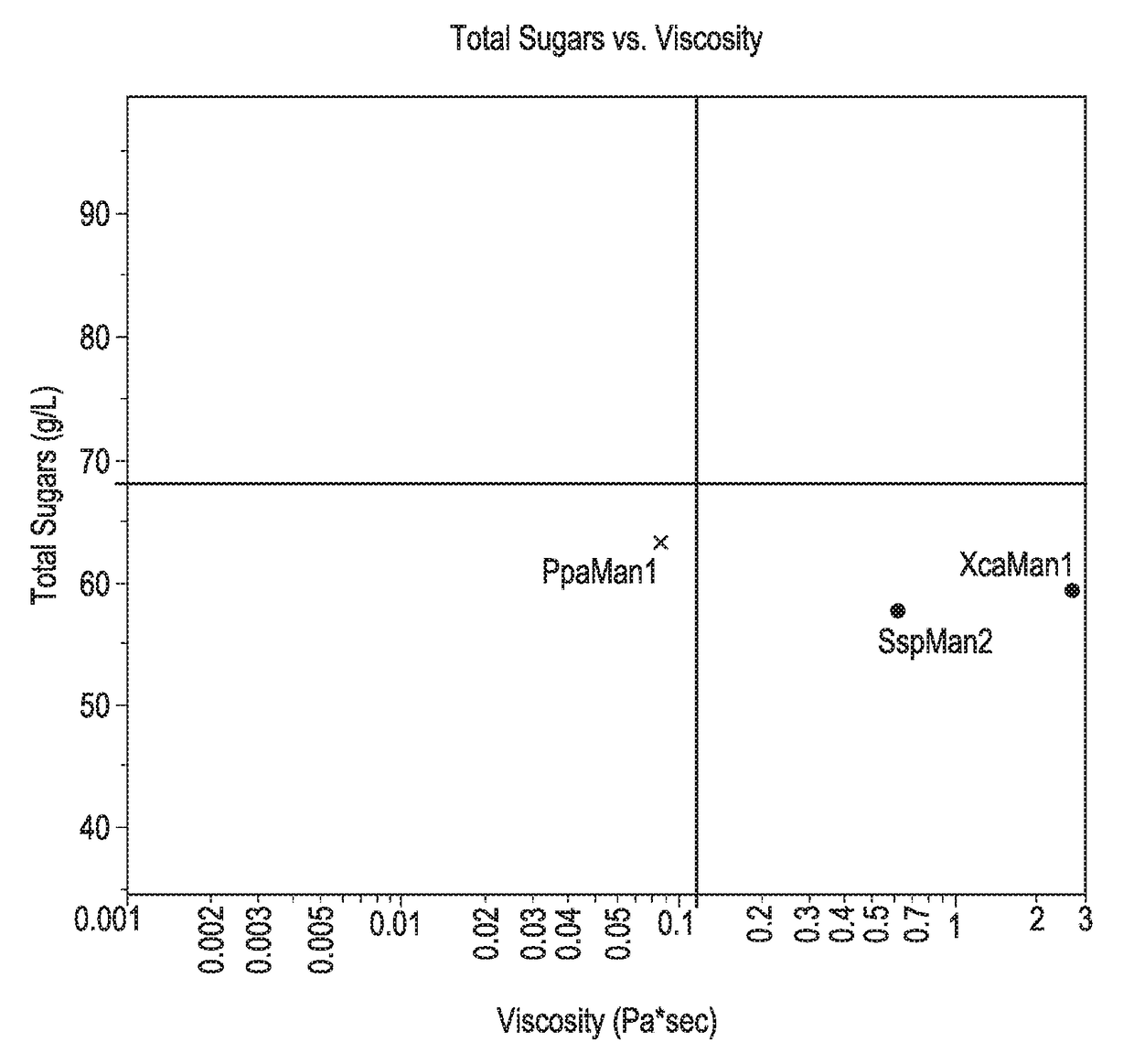

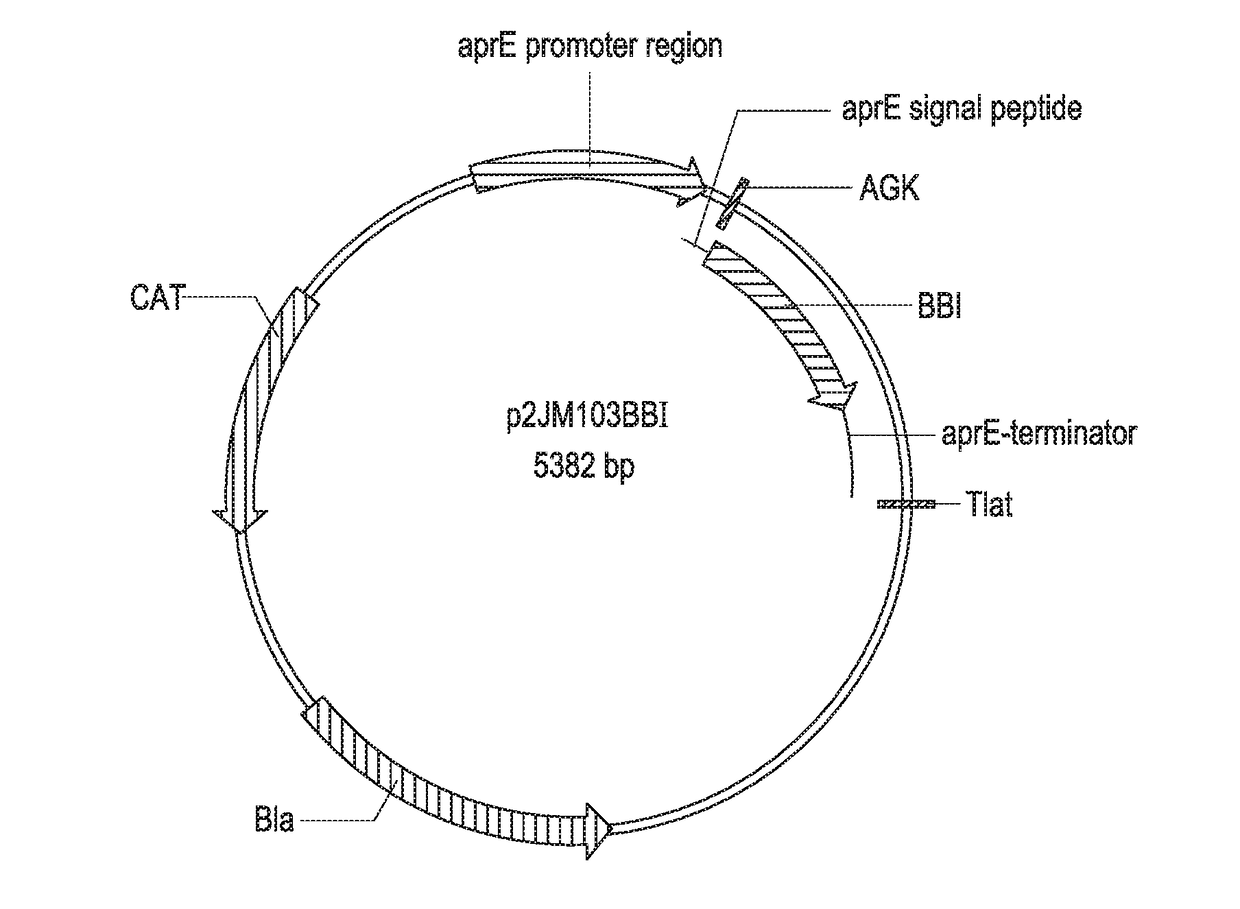

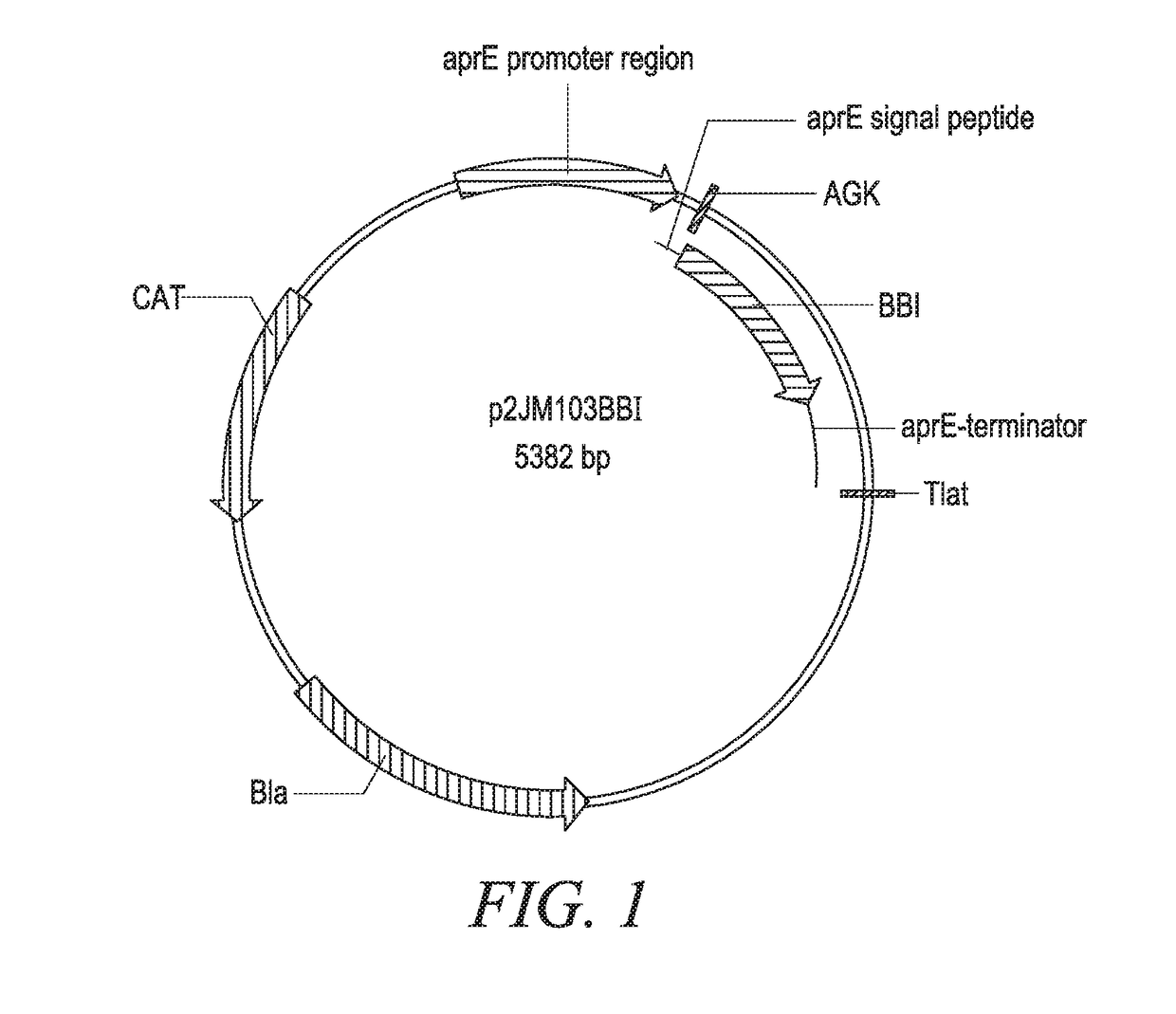

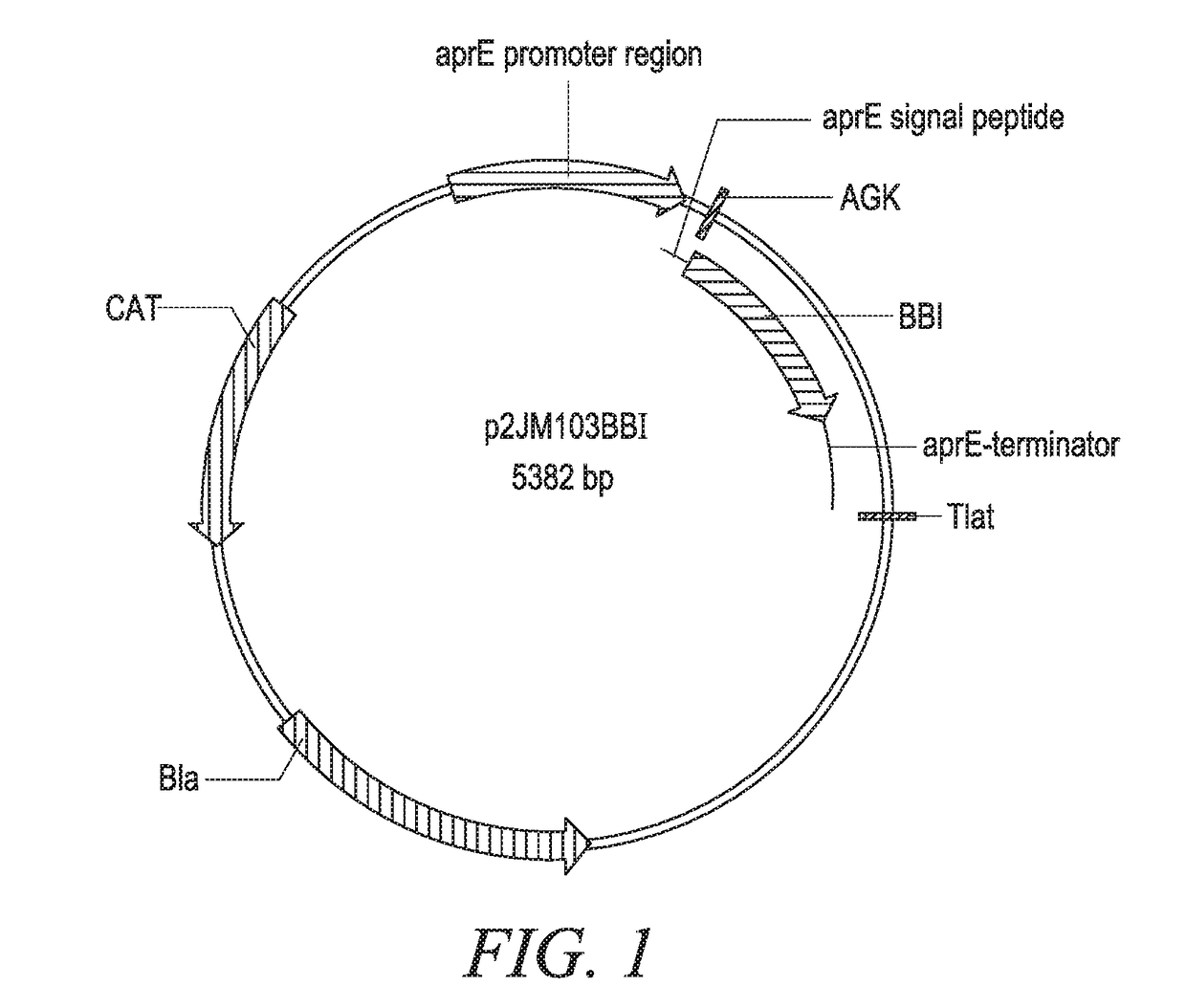

Compositions comprising beta mannanase and methods of use

InactiveUS20170211052A1Reduce capacityIncrease capacityFermentationGlycosylasesGalactoglucomannanLignocellulosic biomass

The present compositions and methods relate to a beta-mannanase from Mahella australiensis, polynucleotides encoding the beta-mannanase, and methods of make and / or use thereof. Formulations containing the beta-mannanase are suitable for use in hydrolyzing lignocellulosic biomass substrates, especially those comprising a measurable level of galactoglucomannan (GGM) and / or glucomannan (GM).

Owner:DANISCO US INC

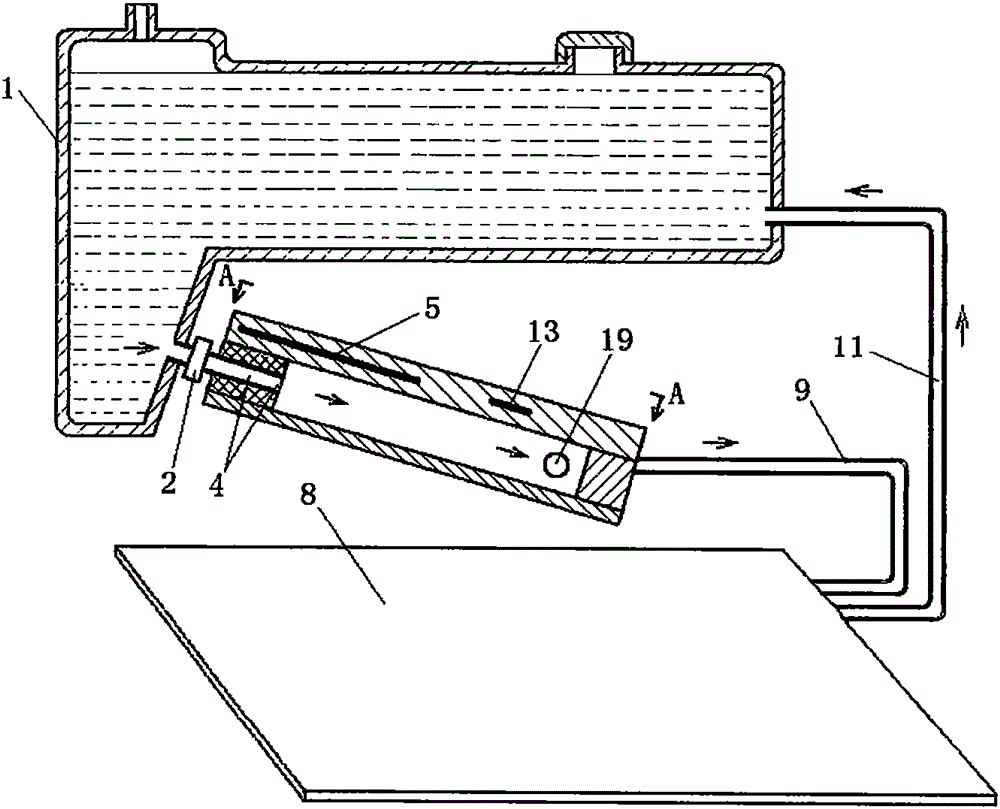

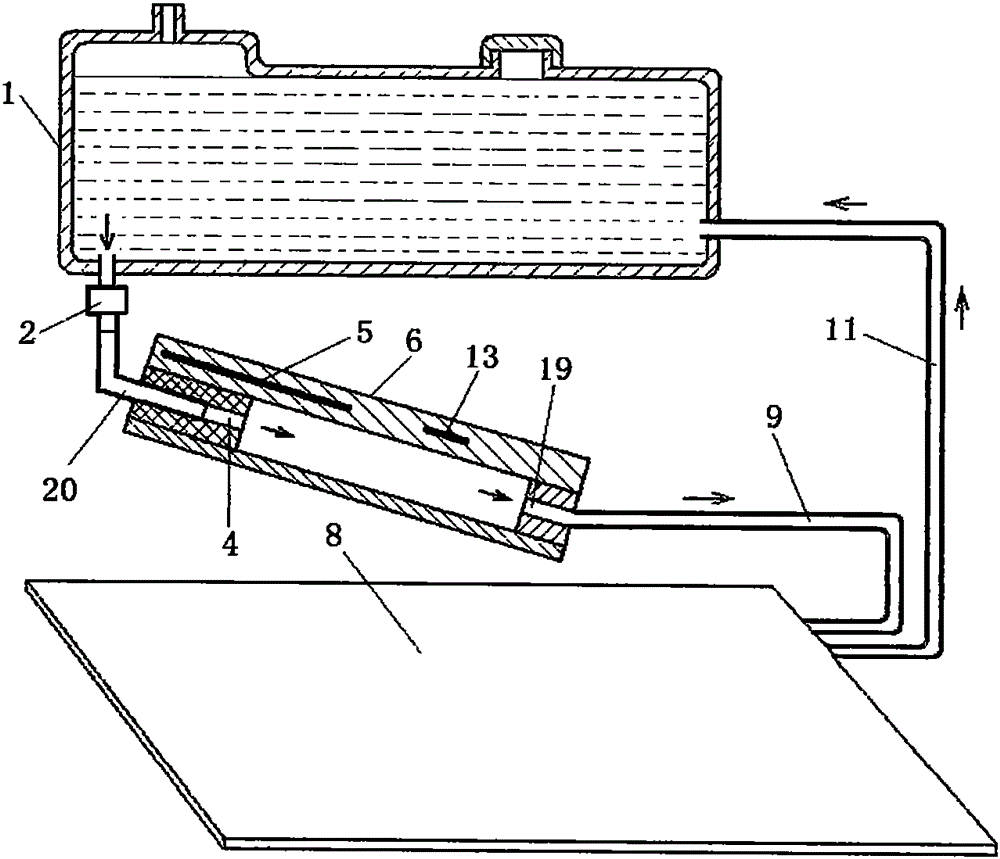

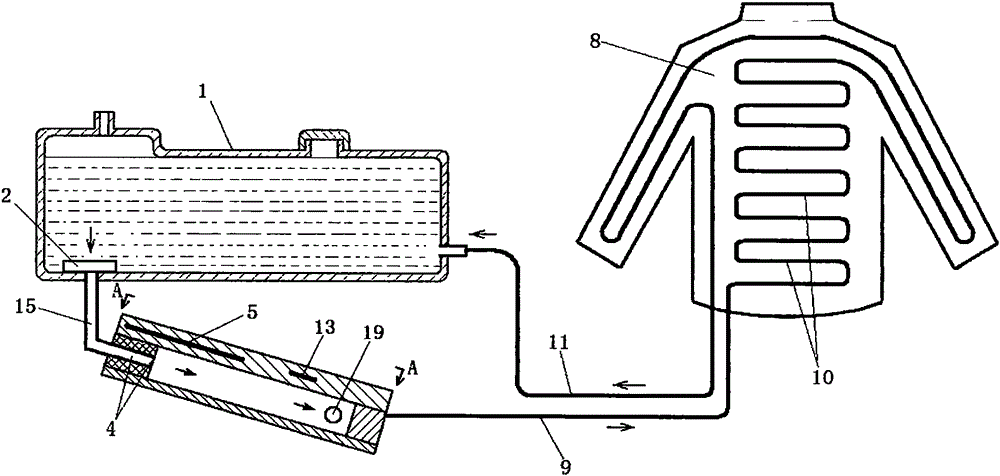

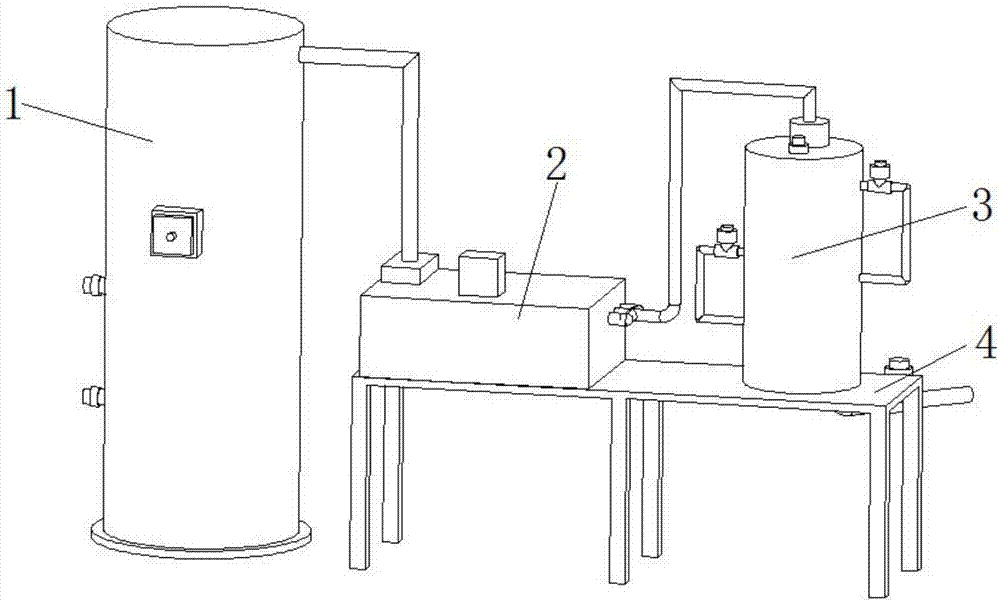

Heat energy water circulation system

InactiveCN105003947ANot easy to loseLarge amount of waterFluid heatersElectric heating systemWater dischargeWater storage tank

The invention relates to a heat energy water circulation system capable of promoting circulating water flowing for heat transfer through water vapor, and aims to provide the heat energy water circulation system which is used for water heating blankets, cushions, quilts, water circulation thermal therapy clothes and the like and has a high heating speed, a high water discharging speed, a low water discharging temperature, a high water circulation speed, a good water return property, high work efficiency and capability of promoting circulatory heat transfer. A water storage tank is communicated with a water return port in a heating container through a water return one-way valve, a water outlet in the heating container is communicated with one end of a water outlet connection pipe, the other end of the water outlet connection pipe is communicated with one end of a radiating pipe, the other end of the radiating pipe is communicated with one end of a water inlet connection pipe, and the other end of the water inlet connection pipe is communicated with the water storage tank; the water return port in the heating container is higher than the water outlet. When an electric heating element is used for heating, the temperature of the area around the water return port in the heating container is higher than that of the area around the water outlet; the cross sectional area of the water return port in the heating container is smaller than or equal to 28 mm<2>; the water return port in the heating container and a heating container body are in insulated connection.

Owner:王彤宇

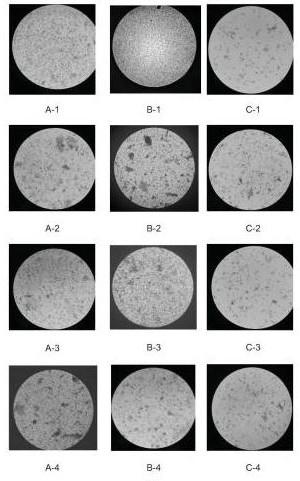

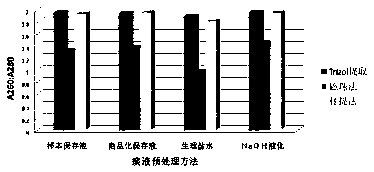

Sputum preserving fluid

The invention provides a sputum preserving fluid. The sputum preserving fluid comprises guanidine salt, a metal chelating agent, a surfactant and the like. The preserving fluid does not contain a strong base component, so that damage to nucleic acid, particularly RNA, is reduced. The preserving fluid can keep a sputum sample stable, rapidly liquefy sputum and inhibit RNA enzyme; and RNA with relatively high purity is obtained, and the detection accuracy is improved. The liquefied sputum sample is directly subjected to RNA extraction, and the yield and purity are superior to those of a comparison method. The sample preserved by the preserving fluid can be used for various methods such as a paramagnetic particle method, a column extraction method, a cracking method and the like, and interference is avoided. The liquefied sputum sample can be directly used for cytological detection, and influence on cell density or cellular staining is avoided.

Owner:GUANGZHOU LBP MEDICINE SCI & TECH

Household water purifier having good water purification effects

InactiveCN106986491AImplement primary filtrationReasonable structureTreatment involving filtrationMultistage water/sewage treatmentParticulatesActivated carbon filtration

The invention discloses a household water purifier having good water purification effects. The household water purifier comprises a shell. The bottom in the shell is provided with a filter box. An activated carbon filter layer, a PP rope filter layer and a silica gel particle filter layer are orderly arranged in the filter box from top to bottom. The top end of the filter box is connected to a water conduit. The upper end of the water conduit is connected to a heating box. The lower end of the heating box is connected to a hot water pipe. The lower end of the hot water pipe is connected to a steam generator. A steam generator is arranged at the lower end of the hot water pipe. A heat dissipation block is arranged in the steam generator. The left end of the steam generator is connected to a steam pipe. The left end of the steam pipe is connected to a condensing box. The evaporator is arranged in the condensing box. The upper end of the evaporator is connected to a compressor. The upper end of the compressor is connected to a radiator. The upper end of the condensing box is connected to a cold water pipe. The right end of the cold water pipe is connected to a filter cartridge. The right end of the filter cartridge is connected to a water outlet pipe. The lower end of the middle of the water outlet pipe is connected to a backflush tube. The household water purifier satisfies the standard of healthy drinking, has good purification effects, satisfies needs of domestic water and is worthy of promotion and use.

Owner:陈文华

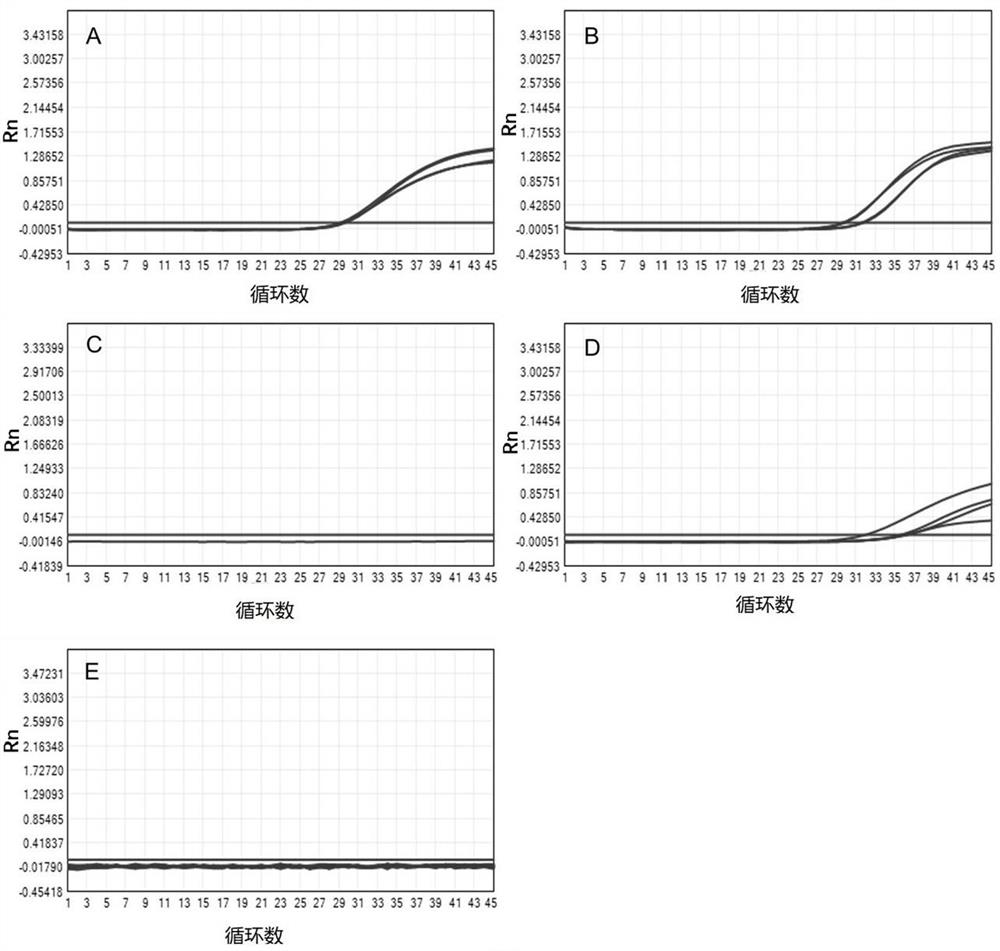

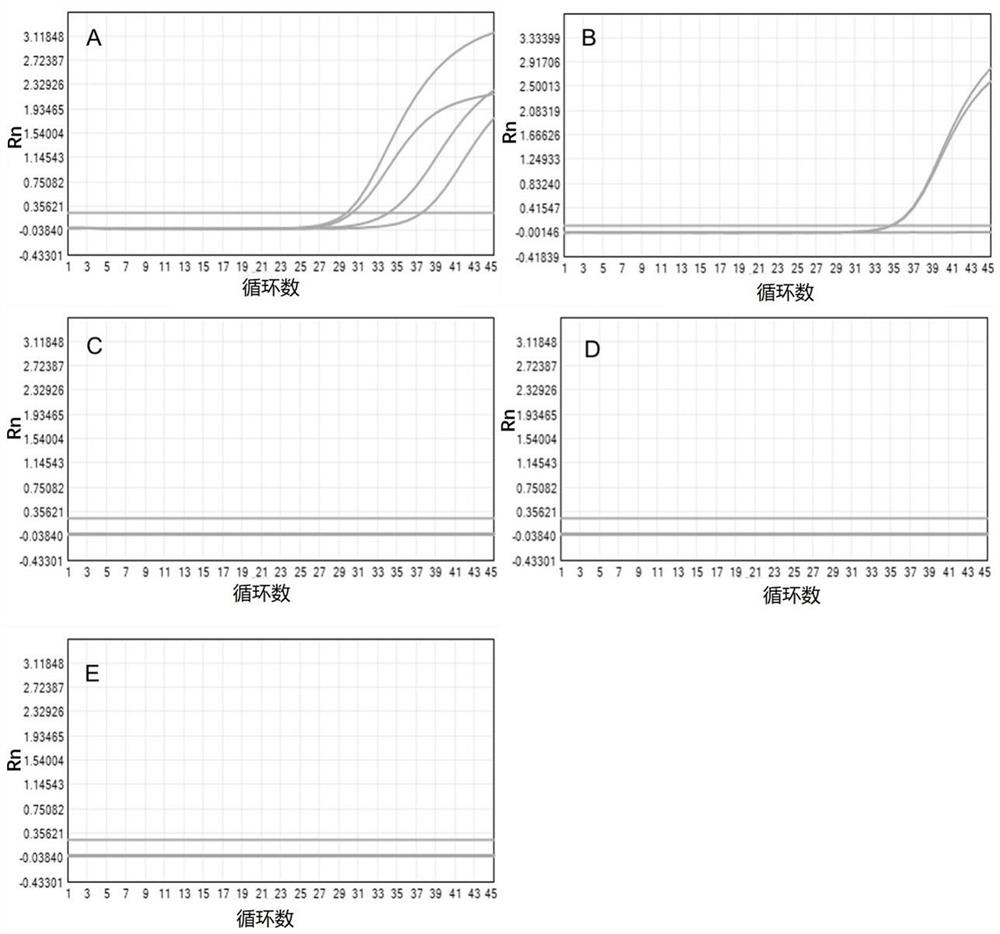

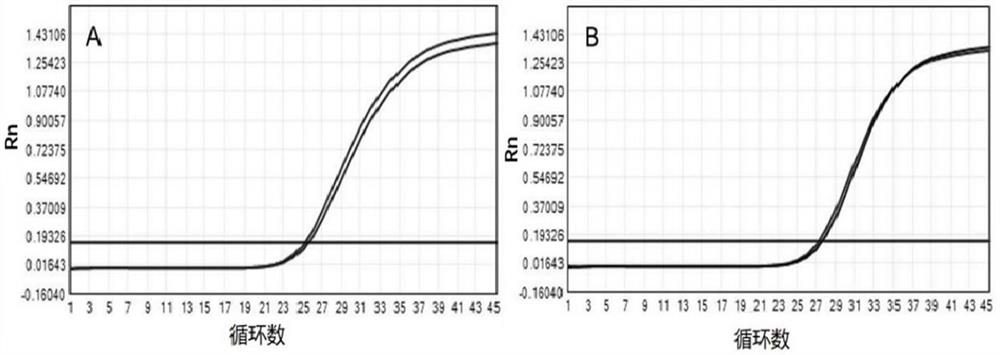

Viscous biological sample liquefaction release combination product, kit, liquefaction release method and nucleic acid extraction, amplification and detection method

ActiveCN114107442AGood release effectGood compatibilityMicrobiological testing/measurementSolventActive agent

The invention relates to a viscous biological sample liquefying and releasing combined product which comprises a liquefying component and a nucleic acid releasing component, wherein the liquefying component comprises guaifenesin and strong base; the nucleic acid release component comprises a component i) and / or a component ii), the component i) comprises 0.1%-2% of Tween 20, 0.1%-3% of Triton X-100, 0.1%-3% of ethyl phenyl polyethylene glycol, 20 mM to 1 M of Na < + > and / or K < + >, 50 mM to 1.25 M of strong base, an adsorbent and an aqueous solvent; and the component ii) comprises 0.01-0.5 mM of a surfactant, 0.01%-2% of dodecylbenzene sulfonate, 50-1.2 M of Na < + > and / or K < + >, 0.05%-1% of ethanol and a third strong base. The nucleic acid release component is matched with the liquefaction component for use, and has a better release effect on RNA and DNA.

Owner:SANSURE BIOTECH

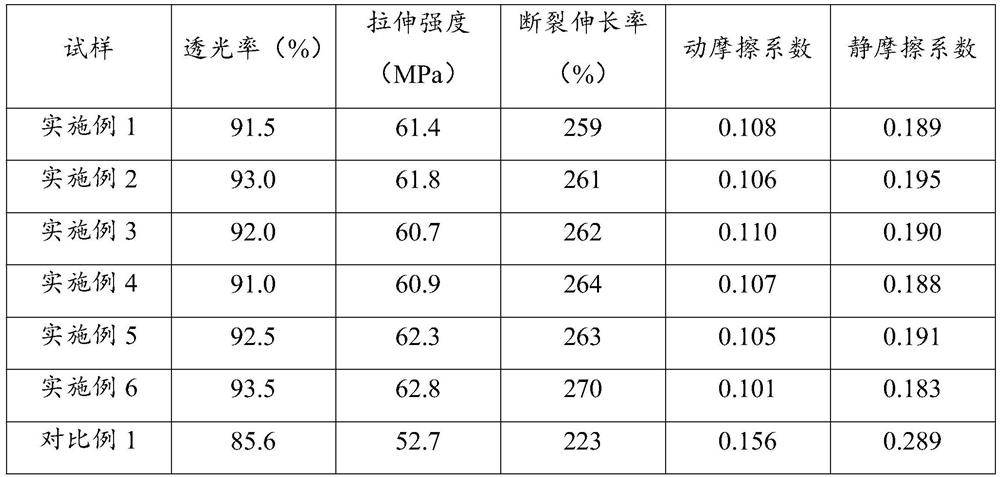

APET composite material and preparation method thereof, keyboard cover, electronic component tray and preparation method thereof

PendingCN111978688AHigh transparencyImprove tensile propertiesPackagingWhitening AgentsElectronic component

The invention is applicable to the technical field of materials, and provides an APET composite material and a preparation method thereof, a keyboard cover, an electronic component tray and a preparation method thereof. The preparation method of the APET composite material comprises the following steps: carrying out ball milling and blending on APET, PETG, modified loess, a whitening agent and a slipping agent according to a specific ratio under the production reaction conditions, heating and stirring, extruding and rolling, cooling and the like to prepare the APET composite material. The transparency of the APET composite material can be remarkably improved, and the tensile property and the slipping property of the APET composite material can be obviously improved.

Owner:深圳市品兴隆塑胶制品有限公司

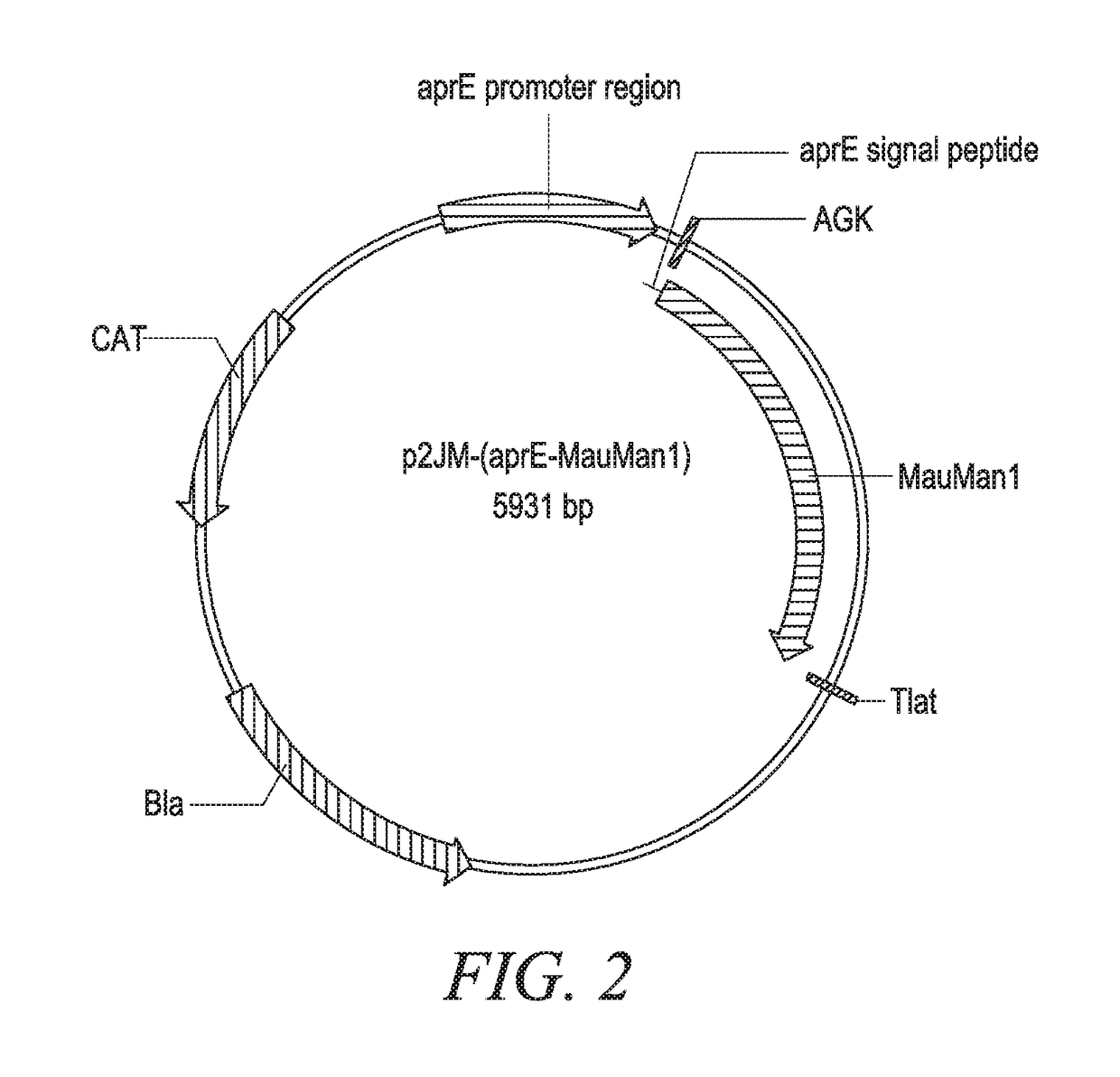

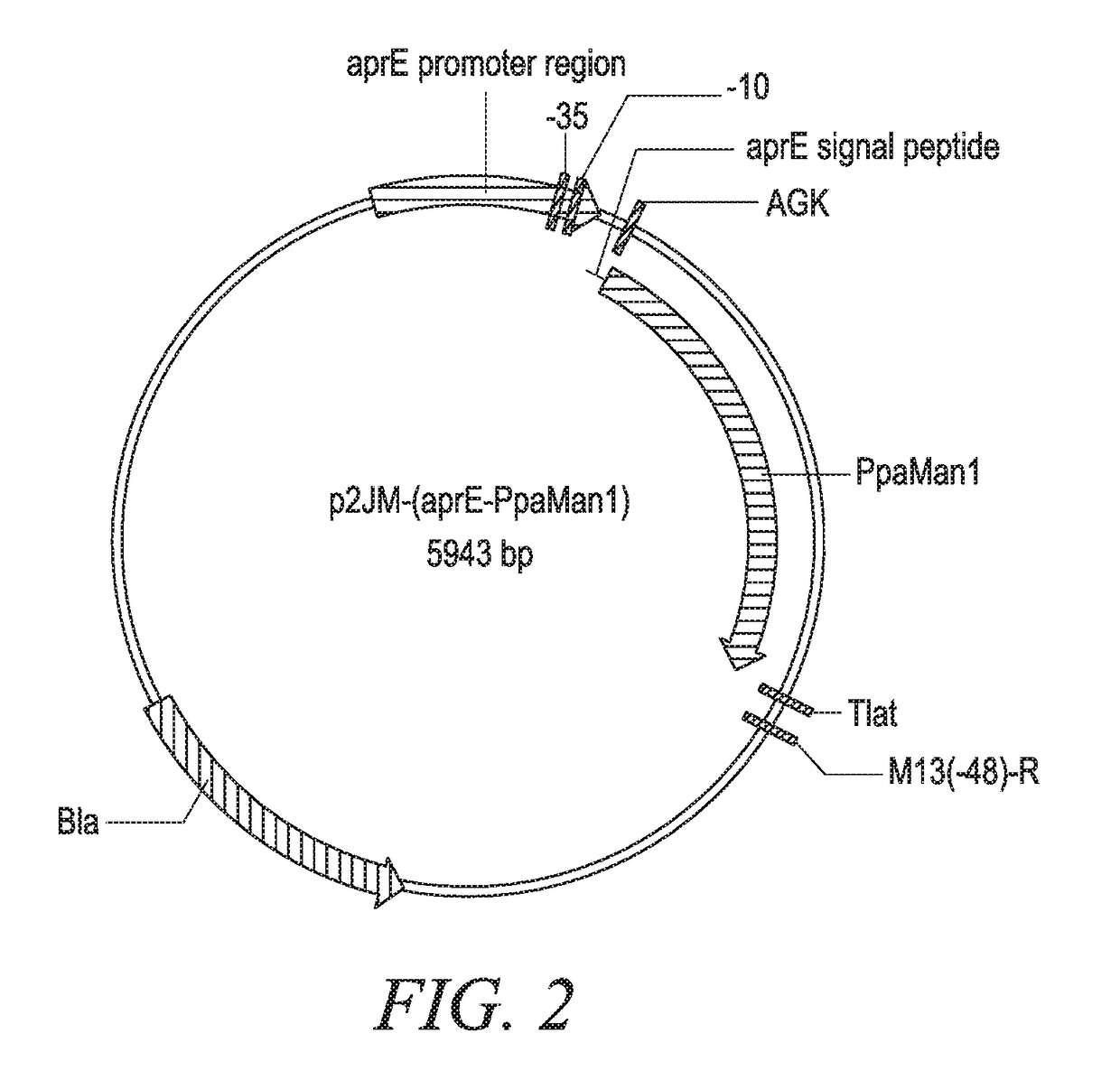

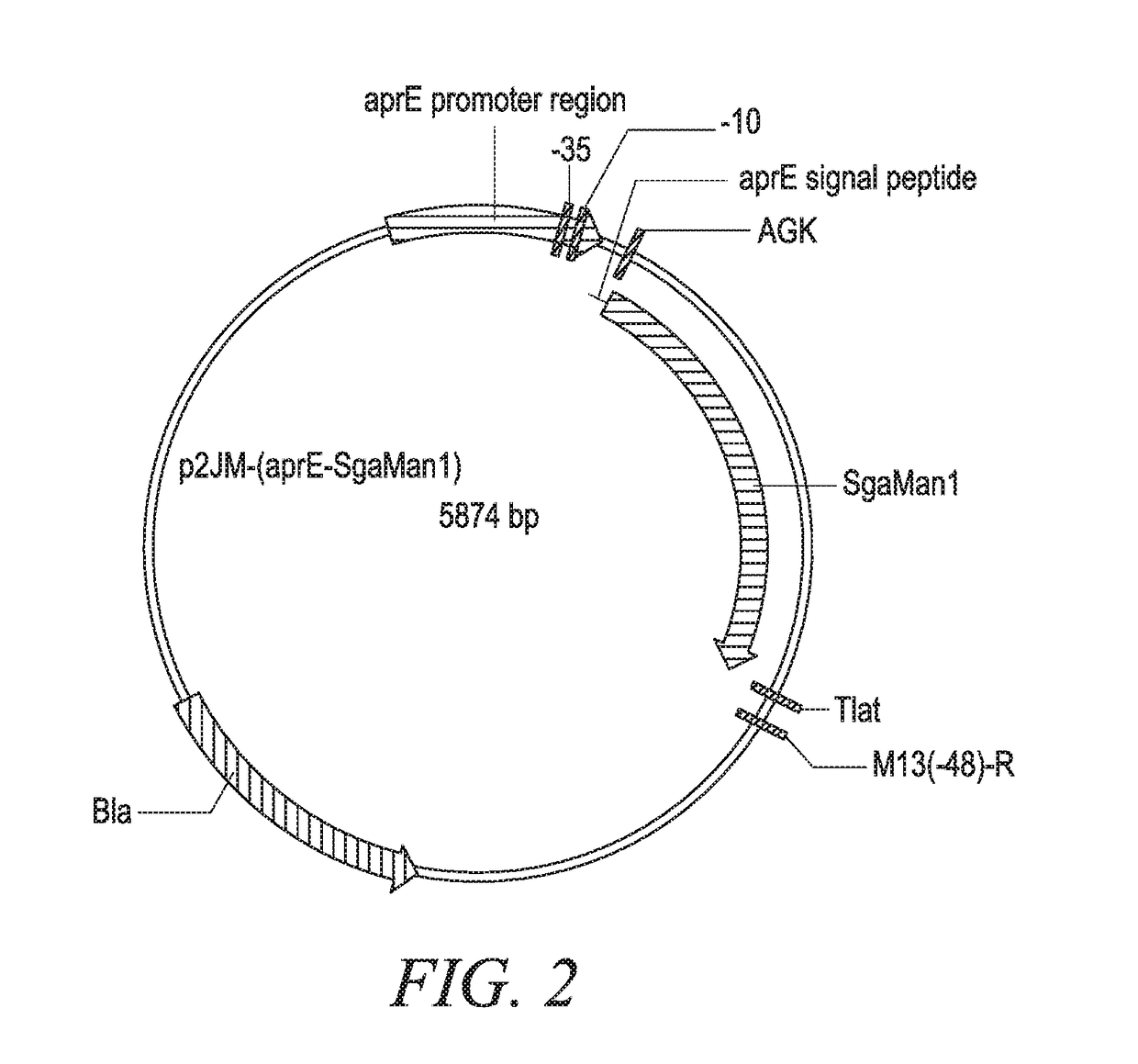

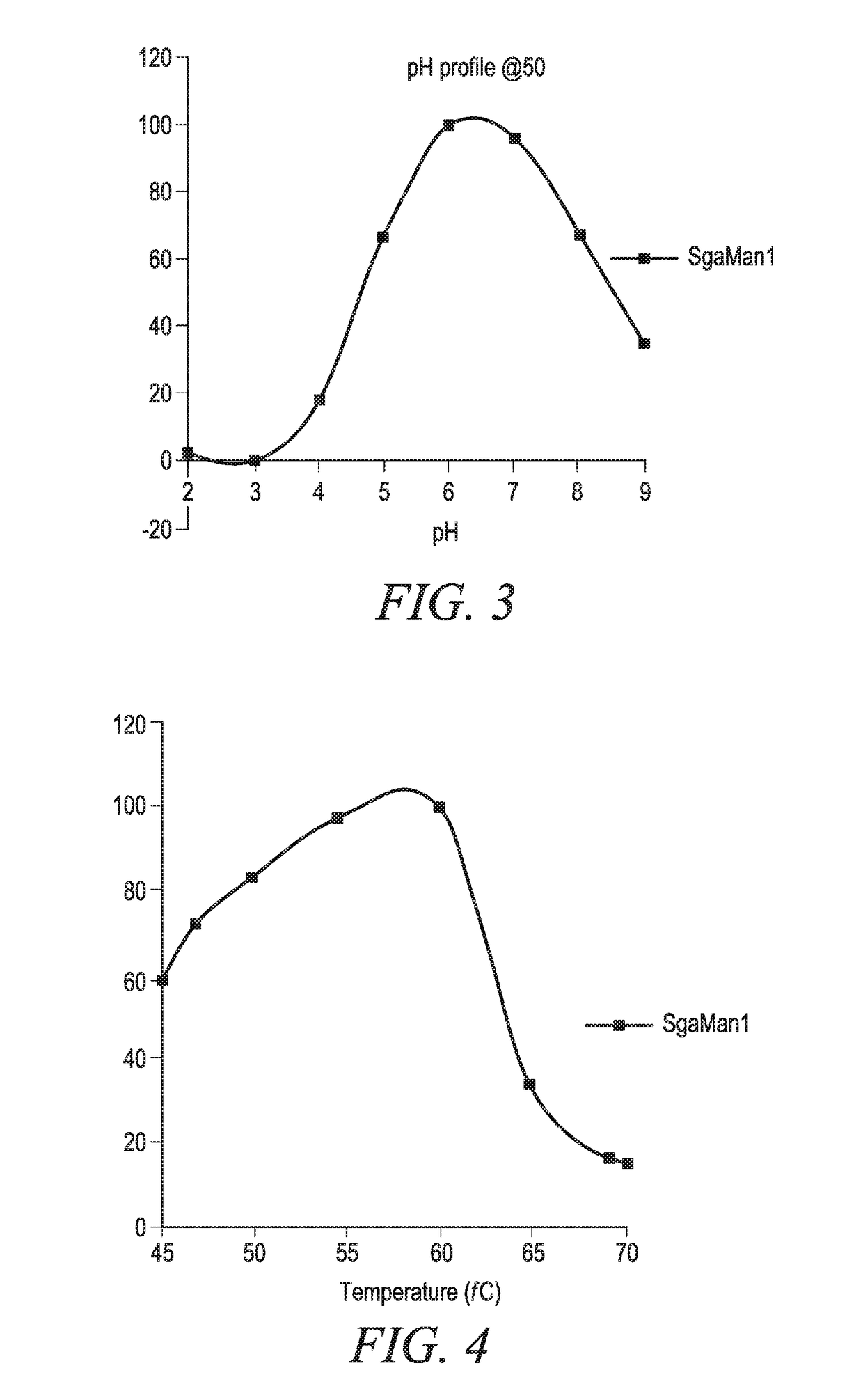

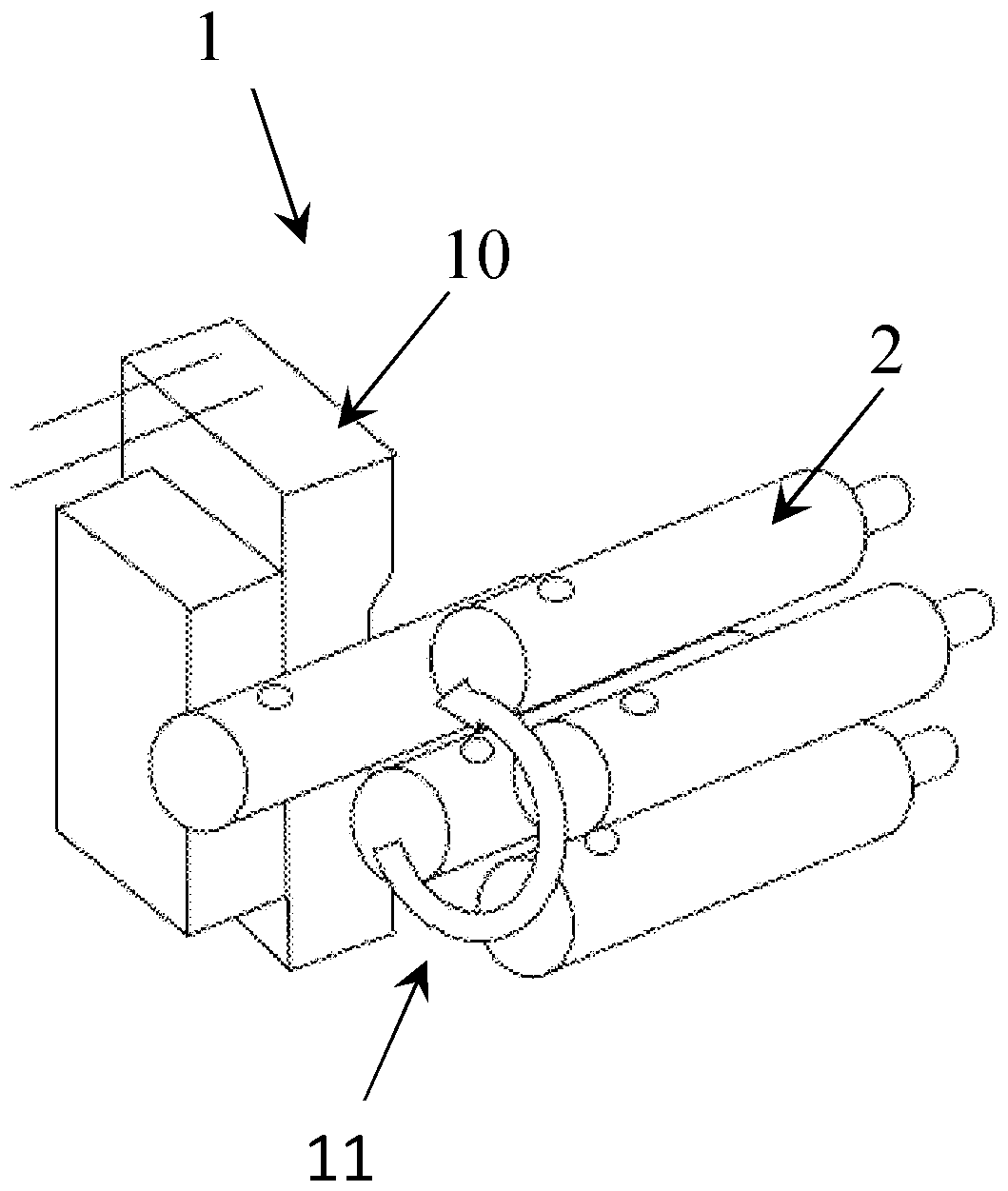

Compositions comprising beta-mannanase and methods of use

InactiveUS20170226494A1Increase capacitySpeed up the conversion processGlycosylasesCelluloseNucleotide

The present compositions and methods relate to a beta-mannanase from Paenibacillus pabuli, polynucleotides encoding the beta-mannanase, and methods of make and / or use thereof. Formulations containing the beta-mannanase are suitable for use in hydrolyzing lignocellulosic biomass substrates, especially those comprising a measurable level of galactoglucomannan (GGM) and / or glucomannan (GM).

Owner:DANISCO US INC

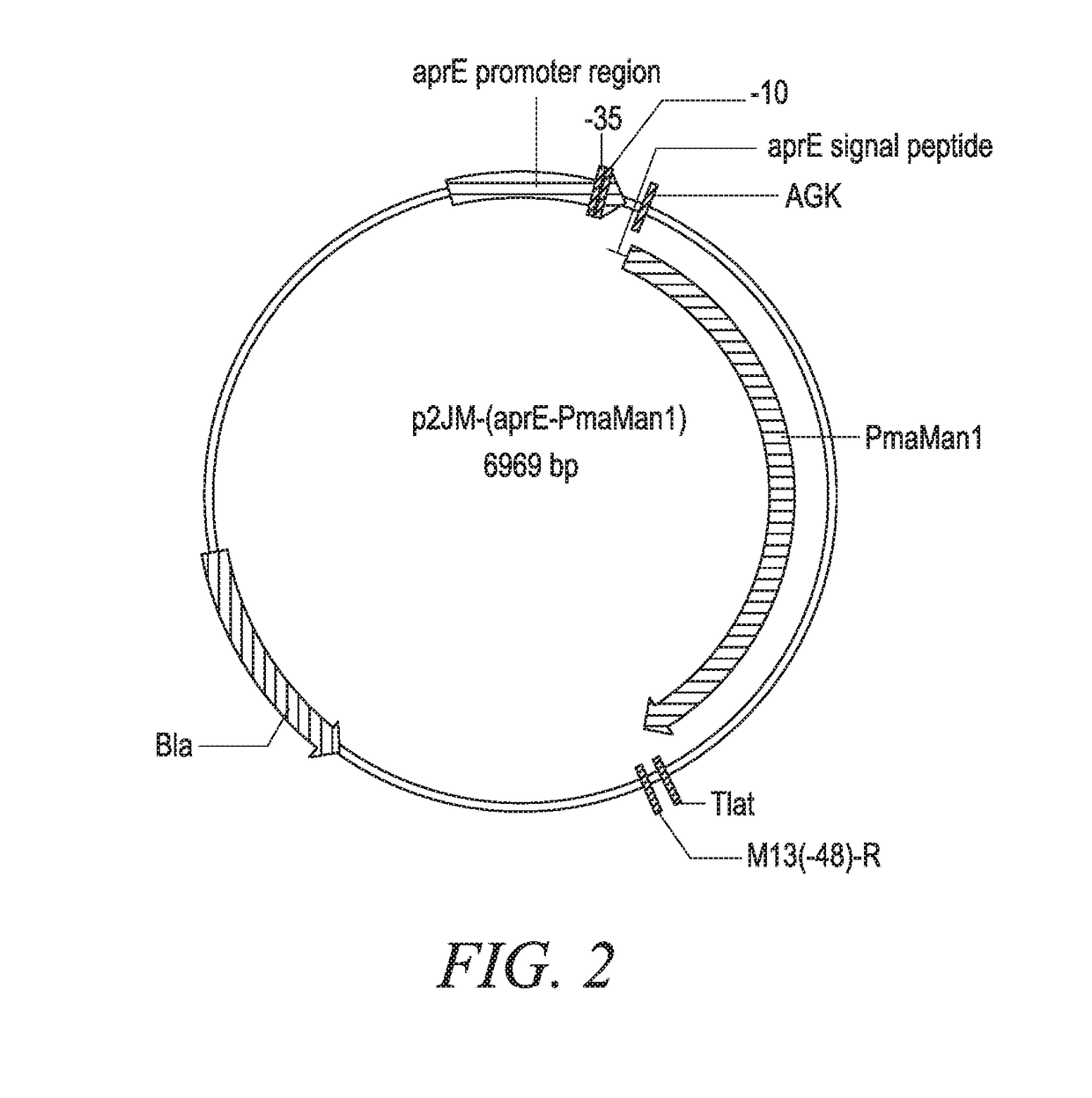

Compositions comprising beta-mannanase and methods of use

InactiveUS20170218351A1Increase capacitySpeed up the conversion processEnzymesFermentationLignocellulosic biomassGalactoglucomannan

The present compositions and methods relate to a beta-mannanase from Paenibacillus macerans, polynucleotides encoding the beta-mannanase, and methods of make and / or use thereof. Formulations containing the beta-mannanase are suitable for use in hydrolyzing lignocellulosic biomass substrates, especially those comprising a measurable level of galactoglucomannan (GGM) and / or glucomannan (GM).

Owner:DANISCO US INC

Rapid combustible ice supercooling nano liquefier and method for exploiting combustible ice with same

PendingCN110527498AHigh flash pointFast liquefactionFluid removalDrilling compositionChemistryKetone

The invention discloses a rapid combustible ice supercooling nano liquefier and a method for exploiting combustible ice with same, aims to achieve safe, environment-friendly, economic and effective combustible ice exploitation and has excellent development prospects. The rapid combustible ice supercooling nano liquefier comprises the following components in percentage by mass: 0-25% of ammonium salt, 0-25% of an acid, 10-80% of a penetrant, 0-25% of amide, 5-70% of an ester, 2-40% of an ether, 0-35% of an alcohol, 0-25% of ketone and 0-35% of aldehyde. According to rock ore components, the liquefier which has an ice point of minus 200 DEG C to minus 10 DEG C and is high in flash point, high in rock dissolution rate, large in permeability, low in injection pressure, rapid in injection pressure drop, long in effective supercooling liquid liquidation distance between single wells and group wells, large in volume, rapid in supercooling liquidation speed and safe and environment-friendly can be prepared, and low-cost large-scale long-term production of methane gas from combustible ice is rapidly achieved initially in the whole world.

Owner:CHENGDU NENGSHENGCAI SCI & TECH DEV CO LTD +1

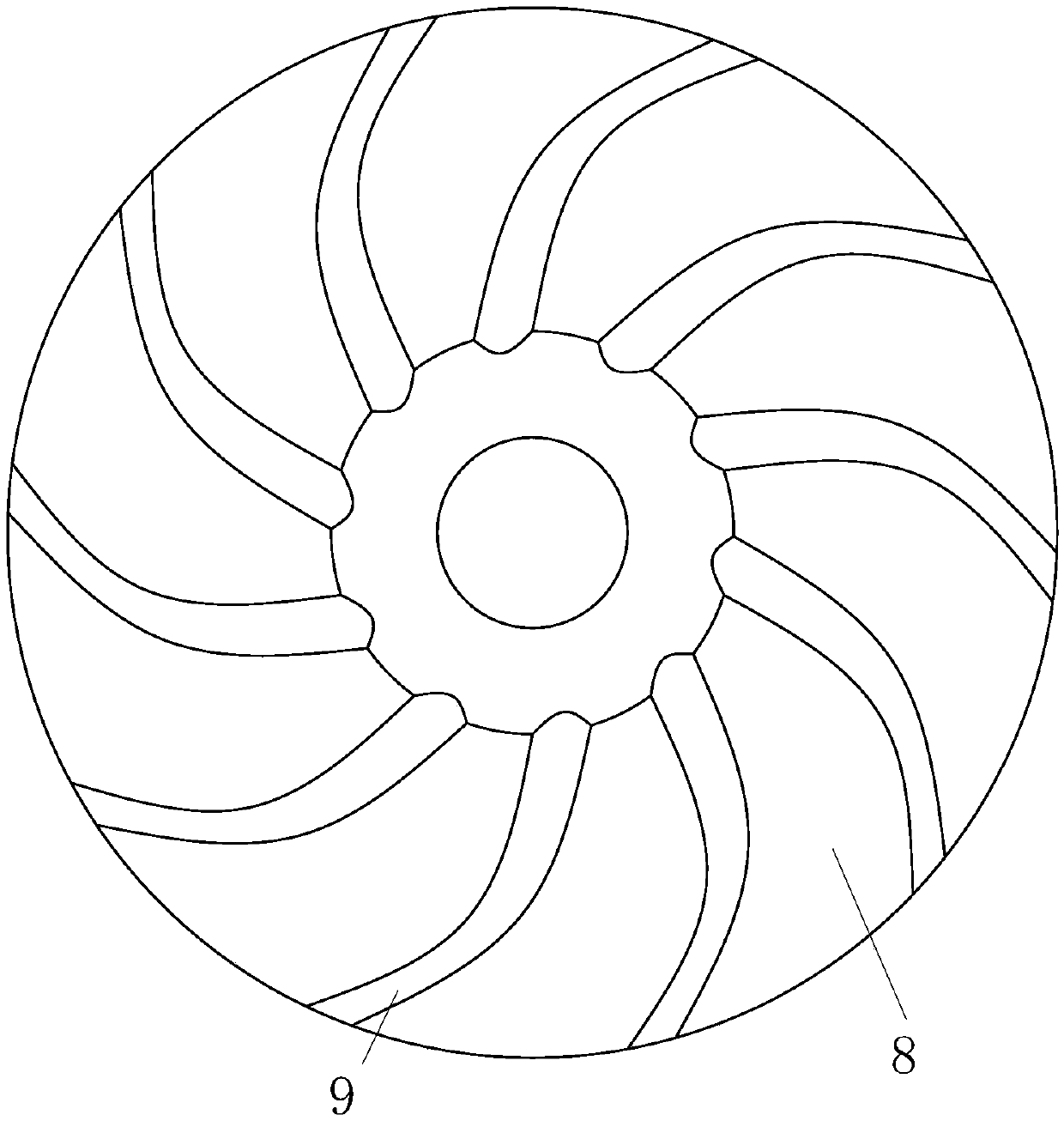

White spirit flavor substance extraction device

PendingCN113980771AImprove liquiditySpeed up coolingAlcoholic beverage preparationEssential-oils/perfumesPhysicsEngineering

The invention discloses a white spirit flavor substance extraction device. Thedevicecomprises a supporting frame, and a motor is fixedly connected to the top end of the supporting frame. The white spirit flavor substance extraction device is characterized in that an output shaft of the motor is fixedly connected with a rotating shaft, and a current converter is arranged at the end, close to the motor, of the rotating shaft and rotationally connected with the rotating shaft, the end, away from the motor, of the supporting frame is fixedly connected with a cooling bin, the rotating shaft is rotationally connected with the cooling bin, the end, close to the cooling bin, of the rotating shaft penetrates through the cooling bin and extends into the cooling bin, a gear is arranged at the end, close to the cooling bin, of the rotating shaft and fixedly connected with the rotating shaft, one end, away from the gear, of the rotating shaft is fixedly connected with a first impeller and a second impeller, and the inner wall of the cooling bin is provided with a scraper. According to the white spirit flavor substance extraction device, the temperature of white spirit steam can be continuously and rapidly reduced, heat exchange between the steam and a cooling device is accelerated, the steam is rapidly liquefied, liquefied substances can be rapidly collected, and the extraction rate of flavor substances in white spirit is increased.

Owner:惠风酒业发展(上海)有限公司

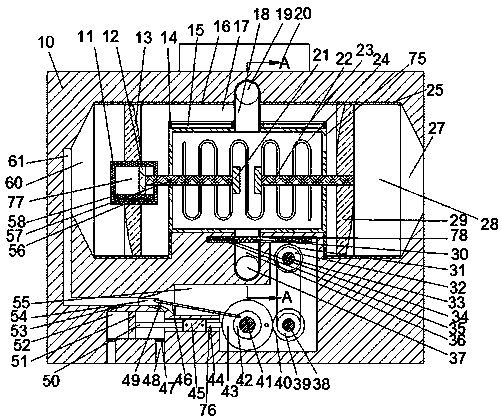

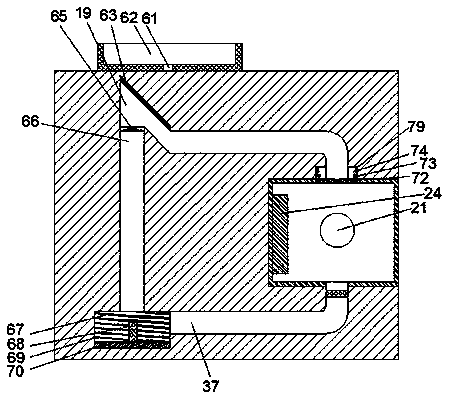

Efficient distillation production device of turpentine oil

PendingCN106861221AIncrease internal spaceRapid liquefactionTurpentine spiritsFractional distillationDistillationEngineering

The invention discloses an efficient distillation production device of turpentine oil. The efficient distillation production device comprises a furnace base, an electric heating furnace, a distillation reaction tower, a liquefaction tank, an oil-water separation tower and a cooler, wherein the electric heating furnace is arranged in the furnace base; the distillation reaction tower is arranged on the electric heating furnace; a motor is arranged at the upper part of the inner cavity of the distillation reaction tower; a motor shaft of the motor is fixedly connected with stirring rods; the top end of the distillation reaction tower is in through connection with a gas storage tank; the top end of the gas storage tank is in through connection with an exhaust cylinder; the outer side of the exhaust cylinder is sleeved with the liquefaction tank; a spiral cooling pipeline is arranged inside the inner wall of the liquefaction tank; cooling pipes are arranged in the cooler; a plurality of heat dissipation plates are uniformly arranged on the peripheral surface of each cooling pipe. According to the efficient distillation production device of turpentine oil, the liquefaction tank is directly connected with the distillation reaction tower through the exhaust cylinder, so that the evaporated oil gas can be rapidly liquefied; the production speed is improved; the productivity is improved; the accumulation of the oil gas in the distillation reaction tower is reduced; meanwhile, the gas storage tank can expand the inner space of the distillation reaction tower, so that the accumulation of the oil gas in the distillation reaction tower can be effectively prevented.

Owner:惠安县丽佳智能设备有限公司

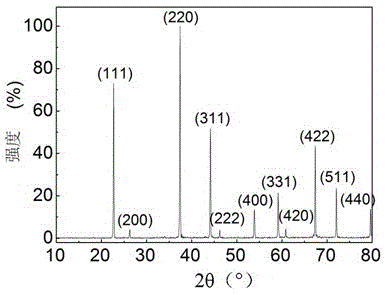

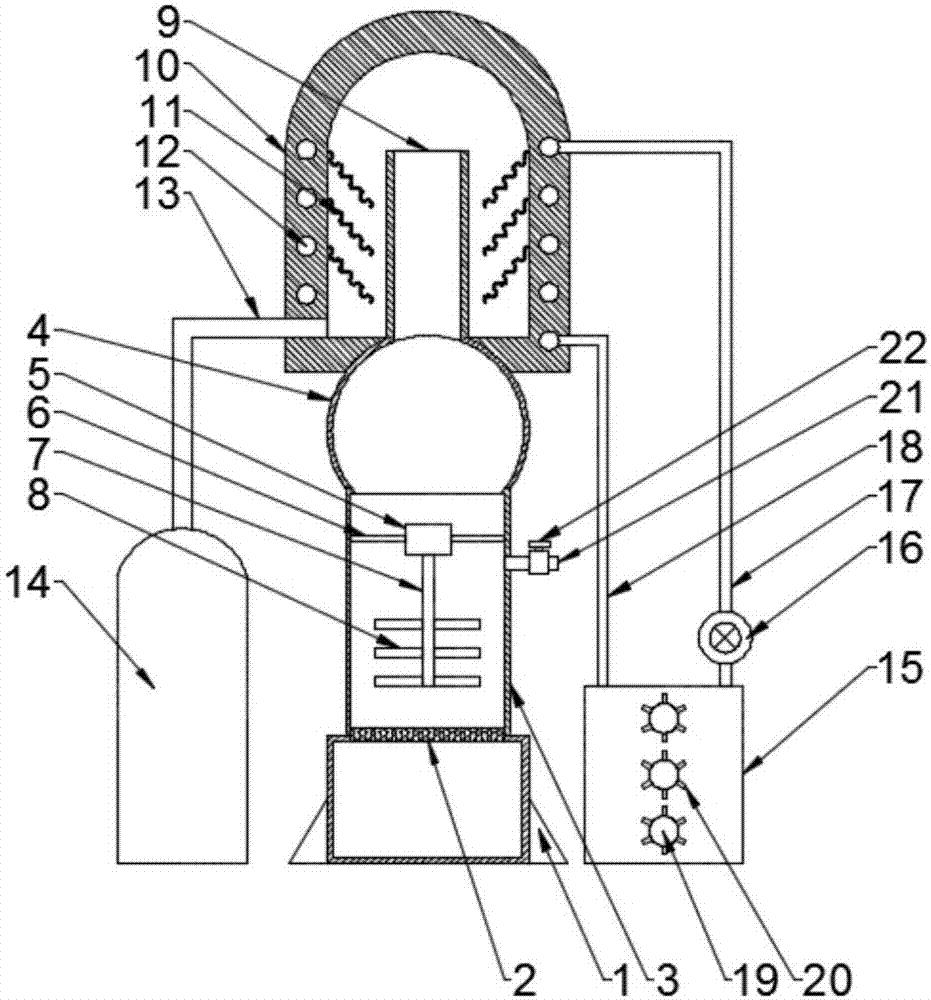

High-carbon chromium steel carbide ultra-refining treatment device

InactiveCN109182693ASimple structureEasy to operateQuenching agentsQuenching devicesChromiumEngineering

The invention discloses a high-carbon chromium steel carbide ultra-refining treatment device which comprises a rack. A steam cavity is arranged in the rack. A heating box is arranged in the steam cavity. A heating cavity is arranged in the heating box. A heating sheet is fixedly arranged on the rear end wall of the heating cavity. A steam heating box is fixed above the heating box. A steam heatingcavity is arranged in the steam heating box. A communicating first shrinkage cavity is arranged at the left end of the steam cavity. A vertical air conveying cavity is arranged on the left side of the first shrinkage cavity. A communicating spiral cavity is arranged on the right side of the steam cavity. An exhaust cavity communicating with the outside is arranged on the right side of the spiralcavity. A vertical oil inlet cavity is arranged above the heating cavity. A vertical oil flowing cavity is arranged on the oil inlet cavity. A vertical oil outlet cavity is arranged below the heatingcavity. A vertical oil passing cavity is arranged below the oil outlet cavity.

Owner:新昌县军辉新能源科技有限公司

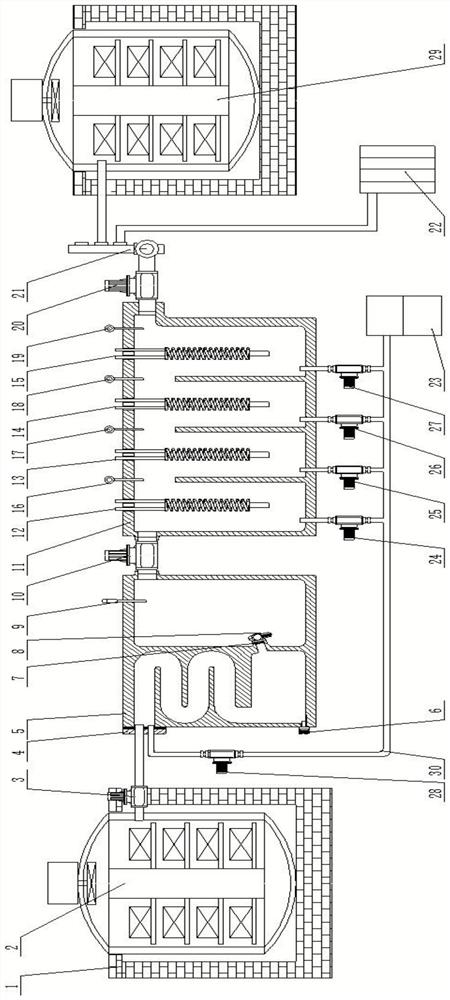

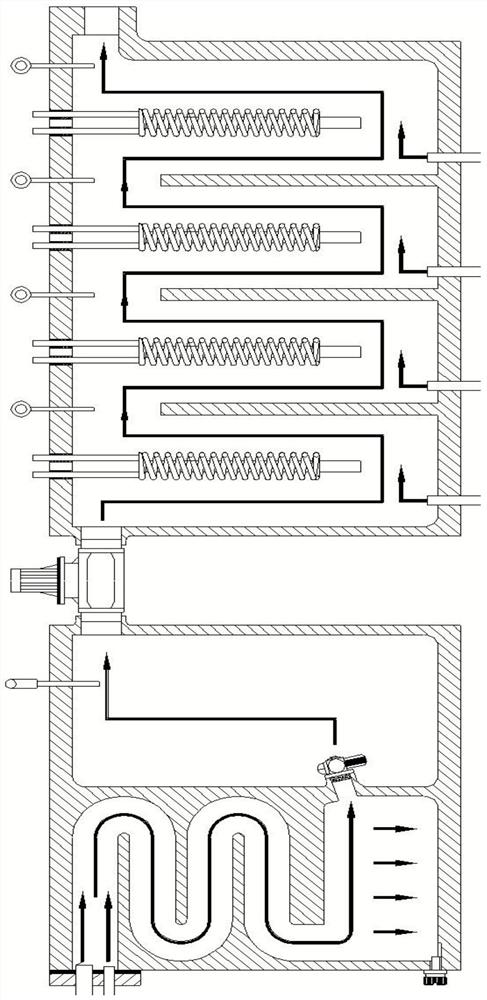

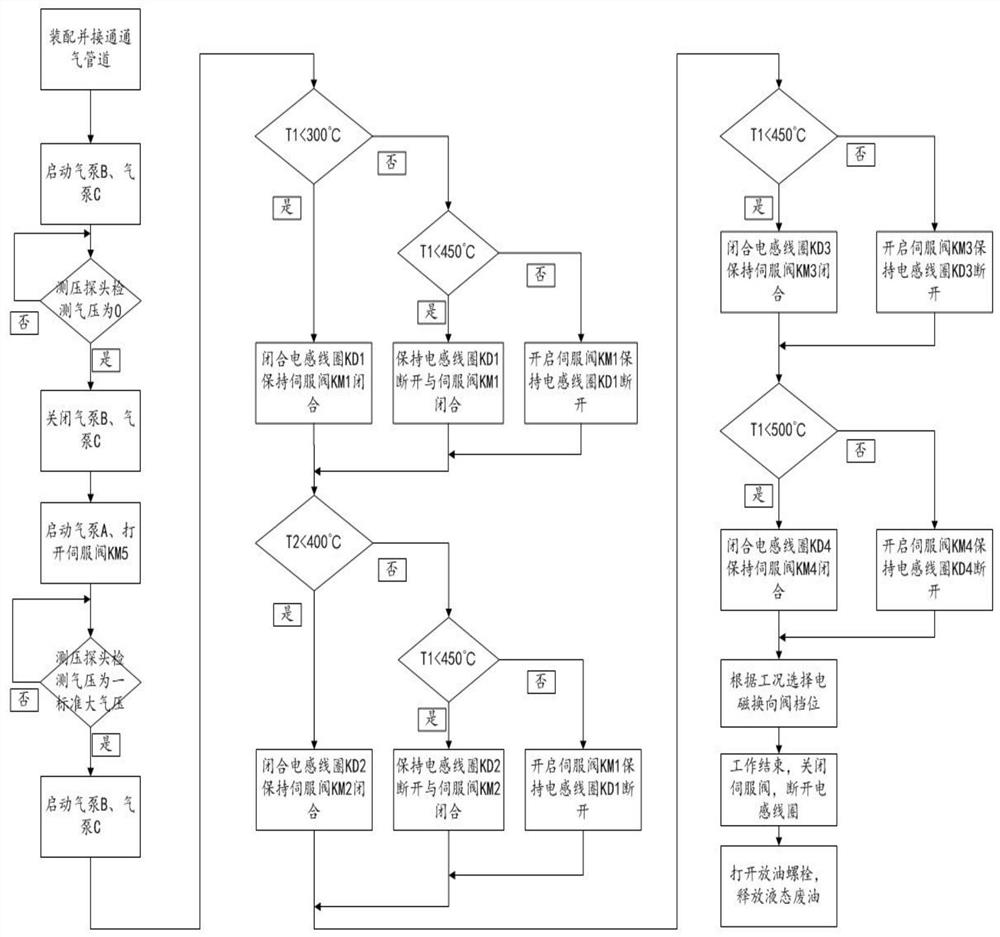

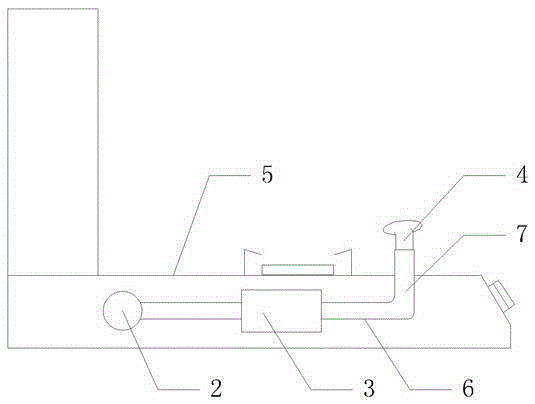

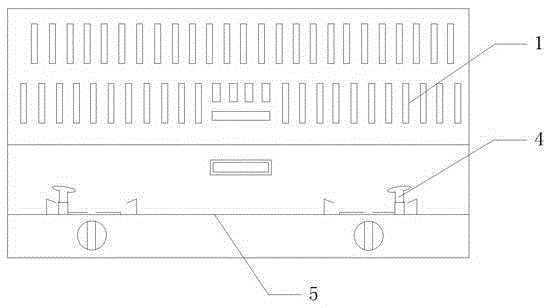

Device and method for recycling nitrogen of annealing furnace

ActiveCN112725597ARapid liquefactionFast driveDispersed particle filtrationTransportation and packagingNitrogen generatorTemperature control

The invention discloses a device and a method for recycling nitrogen of an annealing furnace. The device comprises a heat preservation foundation, a pre-release nitrogen annealing furnace, a first air pump, a condensation tank, a sealing plate, an oil drainage bolt, an oil filter screen, an air source filter, a pressure measuring probe, a second air pump, a temperature control tank, a first inductance coil, a second inductance coil, a third inductance coil, a fourth inductance coil, a first temperature measuring probe, a second temperature measuring probe, a third temperature measuring probe, a fourth temperature measuring probe, a third air pump, an electromagnetic reversing valve, a nitrogen storage tank, a nitrogen generator, a first servo valve, a second servo valve, a third servo valve, a fourth servo valve, a fifth servo valve, a pre-introduced nitrogen annealing furnace and a ventilation pipeline; waste gas in the pre-released nitrogen annealing furnace passes through the condensation tank and the temperature control tank to sequentially achieve purification and precise temperature control of nitrogen in the working process, finally, the nitrogen is directly introduced into the pre-introduced nitrogen annealing furnace, so that a set of complete industrial process is efficiently and orderly realized, and the purpose of recycling the nitrogen of the annealing furnace is fulfilled.

Owner:QINHUANGDAO DONGWU ELECTRONICS

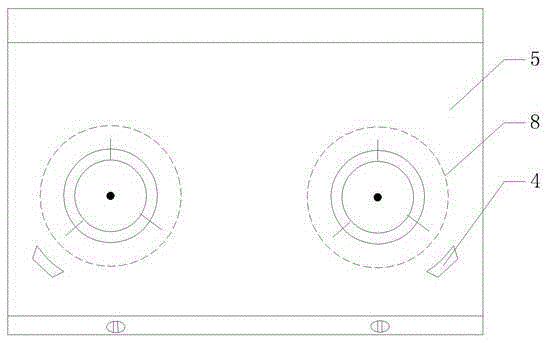

Steam spray degreasing device

InactiveCN103423795BRaise jet elevationJet elevation reducedDomestic stoves or rangesLighting and heating apparatusAbsorption effectOil filter

The invention discloses a jet oil removing device, and relates to the oil stain absorbing technology of a smoke exhauster. The jet oil removing device can solve the problems that the smoke exhauster is poor in oil removing effect and large in workload. The jet oil removing device comprises a fan, a vapor generation device and a vapor feeding nozzle, wherein the fan, the vapor generation device and the vapor feeding nozzle are sequentially connected. The fan and the vapor generation device are located under a cooking bench surface, the vapor feeding nozzle is arranged on the upper portion of the cooking bench surface in front of a cooking bench, the vapor feeding nozzle is connected with the vapor generation device through a vertical vapor feeding pipeline and a horizontal vapor feeding pipeline, the vapor feeding nozzle is provided with a flat nozzle body, the front end of the flat nozzle body is of an inner arc shape, the two side walls of the nozzle body extend outward to form a certain included angle, and the vapor jetting direction of the nozzle body is towards a side absorbing opening. The vapor feeding device is arranged, so that the oil fume diffusion range can be limited, oil fume and vapor can condense quickly to from liquid, the oil fume absorbing effect is improved, and meanwhile workload of an oil filtering device is reduced.

Owner:王先文

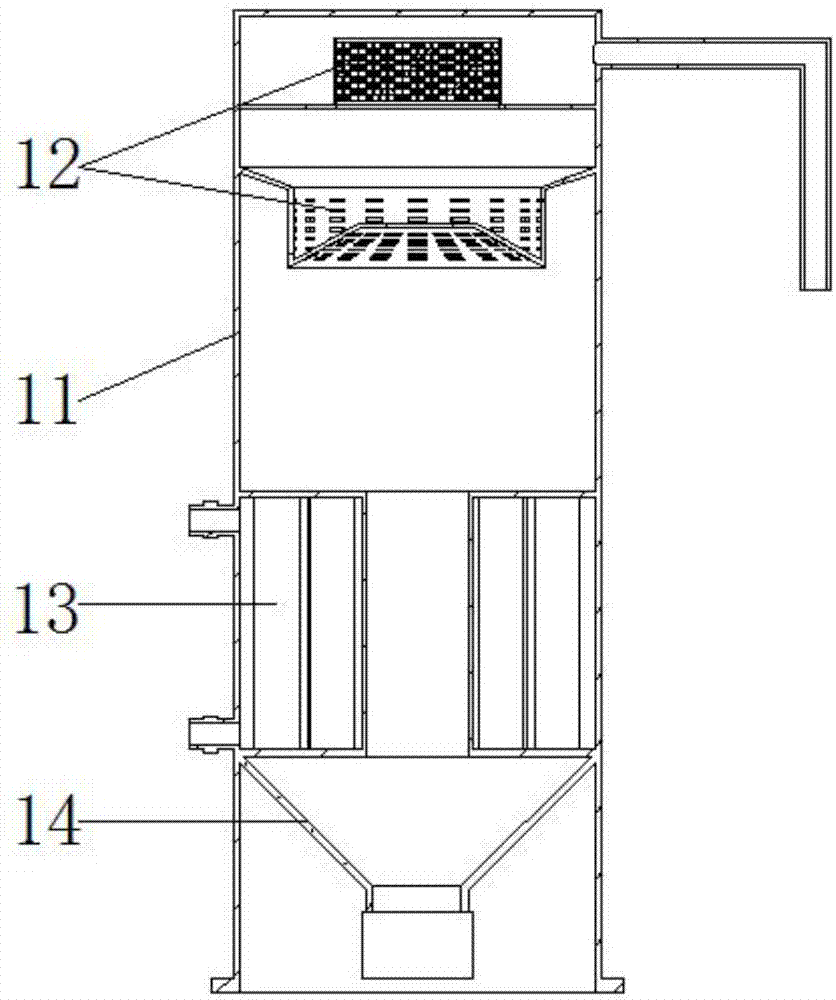

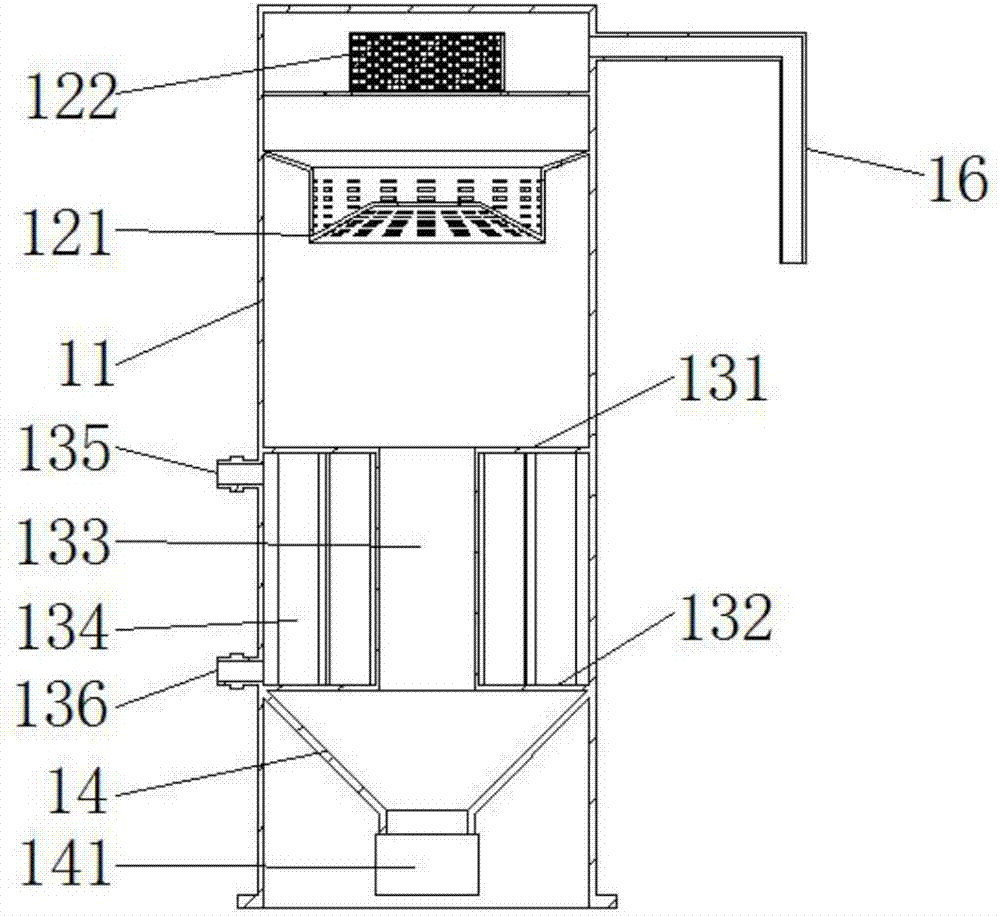

Intelligent treatment equipment system for platemaking waste developing liquid

InactiveCN107200371AEfficient separationEfficient evaporationNature of treatment waterWater/sewage treatment by heatingWater vaporVacuum pump

The invention belongs to the technical field of wastewater treatment and specifically relates to an intelligent treatment equipment system for platemaking waste developing liquid. The intelligent treatment equipment system can be used for evaporating, bubble breaking, condensing and collecting moisture in the printing platemaking waste developing liquid. The system comprises a waste developing liquid evaporating treater and a condenser, wherein a bubble breaking mechanism is arranged in the waste developing liquid evaporating treater, and the condenser is connected with the waste developing fluid evaporating treater. The intelligent treatment equipment system has the beneficial effects that by injecting waste developing liquid into the waste developing liquid evaporating treater and continuously heating the waste developing liquid, the moisture in the waste developing liquid can be evaporated, and the moisture in the waste developing liquid can be effectively separated; bubbles generated by steam can be broken and separated by a large bubble breaking layer and a gas-liquid separating layer, pressure and pressure environment in the equipment are guaranteed, and steam can be quickly inflated into the condenser and quickly liquefied in a multi-branch mode. In addition, a double-layer condensate water temporary storage tank with a constant-pressure assembly and a vacuum pump is used for sucking and storing the liquefied condensate water, so that automatic operation and intelligent treatment of the whole equipment are achieved.

Owner:合肥凯宝乐环境科技有限公司

Compositions comprising beta mannanase and methods of use

InactiveUS20170211053A1Increase capacitySpeed up the conversion processFermentationGlycosylasesGalactoglucomannanLignocellulosic biomass

The present compositions and methods relate to a beta-mannanase from Streptococcus gallolyticus, polynucleotides encoding the beta-mannanase, and methods of make and / or use thereof. Formulations containing the beta-mannanase are suitable for use in hydrolyzing lignocellulosic biomass substrates, especially those comprising a measurable level of galactoglucomannan (GGM) and / or glucomannan (GM).

Owner:DANISCO US INC

Casting of metals

A method for casting metals under pressure by a cold-chamber method includes placing a bolt of the metal to be cast in one of at least two casting chambers and selecting a casting chamber from the atleast two casting chambers and feeding and introducing the selected casting chamber into a die casting machine, the selected casting chamber having one outlet opening. The selecting and feeding of thecasting chambers is carried out alternately from the at least two casting chambers. The method further includes heating the bolt by means of induction. Melting of the bolt in the selected casting chamber is carried out after the feeding and introducing of the selected casting chamber into the die casting machine but before an opening of the outlet opening of the selected casting chamber in orderto fill the cavities is completed.

Owner:乔治费歇尔金属成型科技股份公司

A device for realizing thermal catalytic efficient reduction and recycling of organic waste

ActiveCN107445424BEasy to manageEasy to operateSludge treatmentDispersed particle separationWater treatment systemPtru catalyst

The invention provides a device for achieving thermocatalytic efficient reduction and reclamation of organic wastes. An organic waste feeding system is connected to a proportioning kettle material inlet, the proportioning kettle material outlet is connected to a pre-reaction kettle and the material inlet of a primary reaction kettle, the material outlet of the pre-reaction kettle is connected to the material inlet of the primary reaction kettle, the material outlet of the primary reaction kettle is connected to the material inlet of a cooling kettle, and the material outlet of the cooling kettle is connected to a solid-liquid separation system; a part liquid outlet of the solid-liquid separation system is connected to a water treatment system, and the liquid outlet of the water treatment system is separately connected to the proportioning kettle, the pre-reaction kettle and the material inlet of the primary reaction kettle; a jacket of the primary reaction kettle is connected to a heat source system; the steam outlet of the primary reaction kettle is connected to the proportioning kettle and the steam inlet of the pre-reaction kettle, and the steam outlet of the cooling kettle is connected to the steam outlet of the proportioning kettle; and the cooling water inlet and outlet of the proportioning kettle are connected to the cooling water outlet and inlet of the cooling kettle. The reduction effect of the organic waste is good, a catalyst can be recycled, and the solid product after reaction can be recycled.

Owner:DONGHUA UNIV

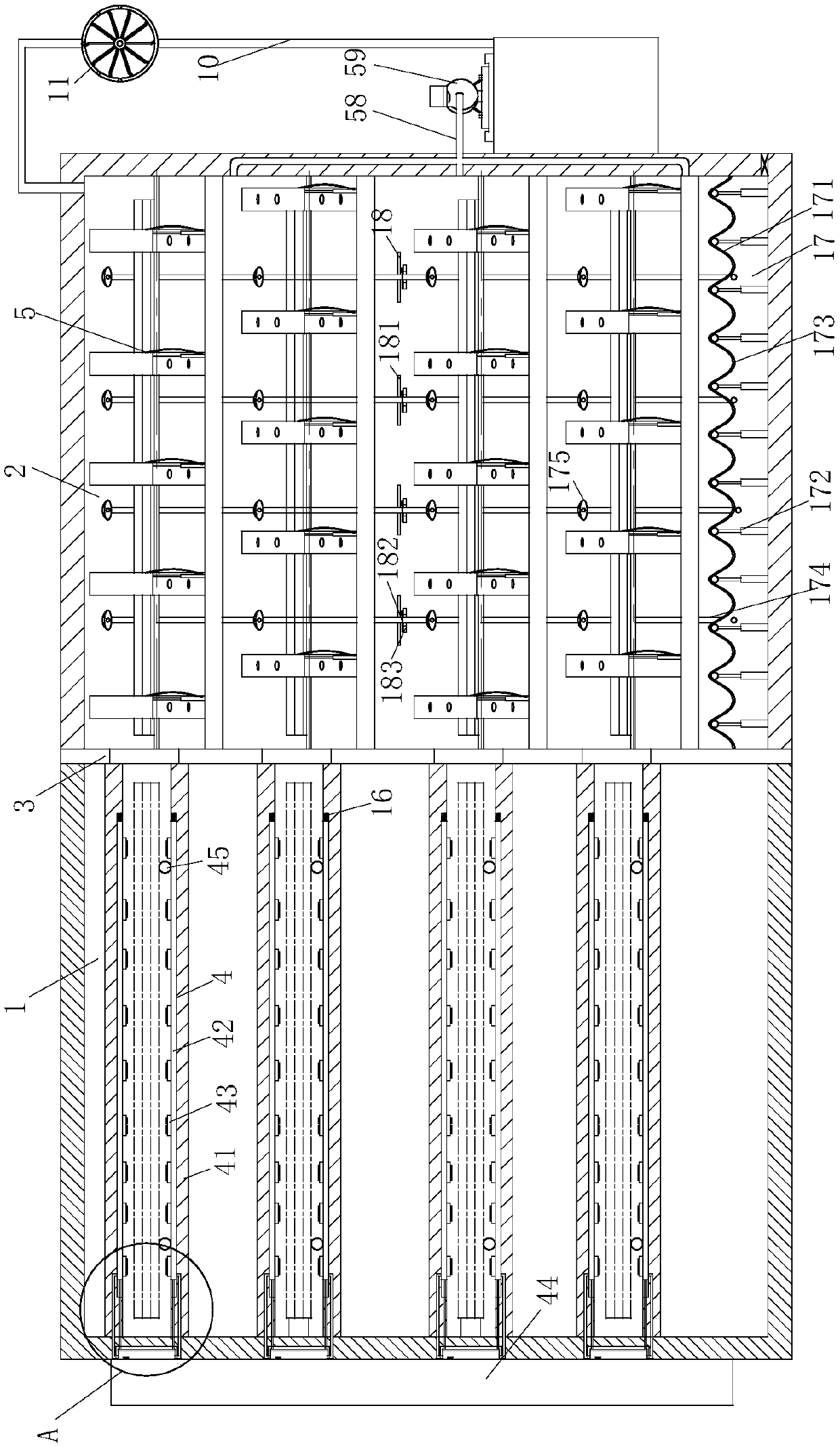

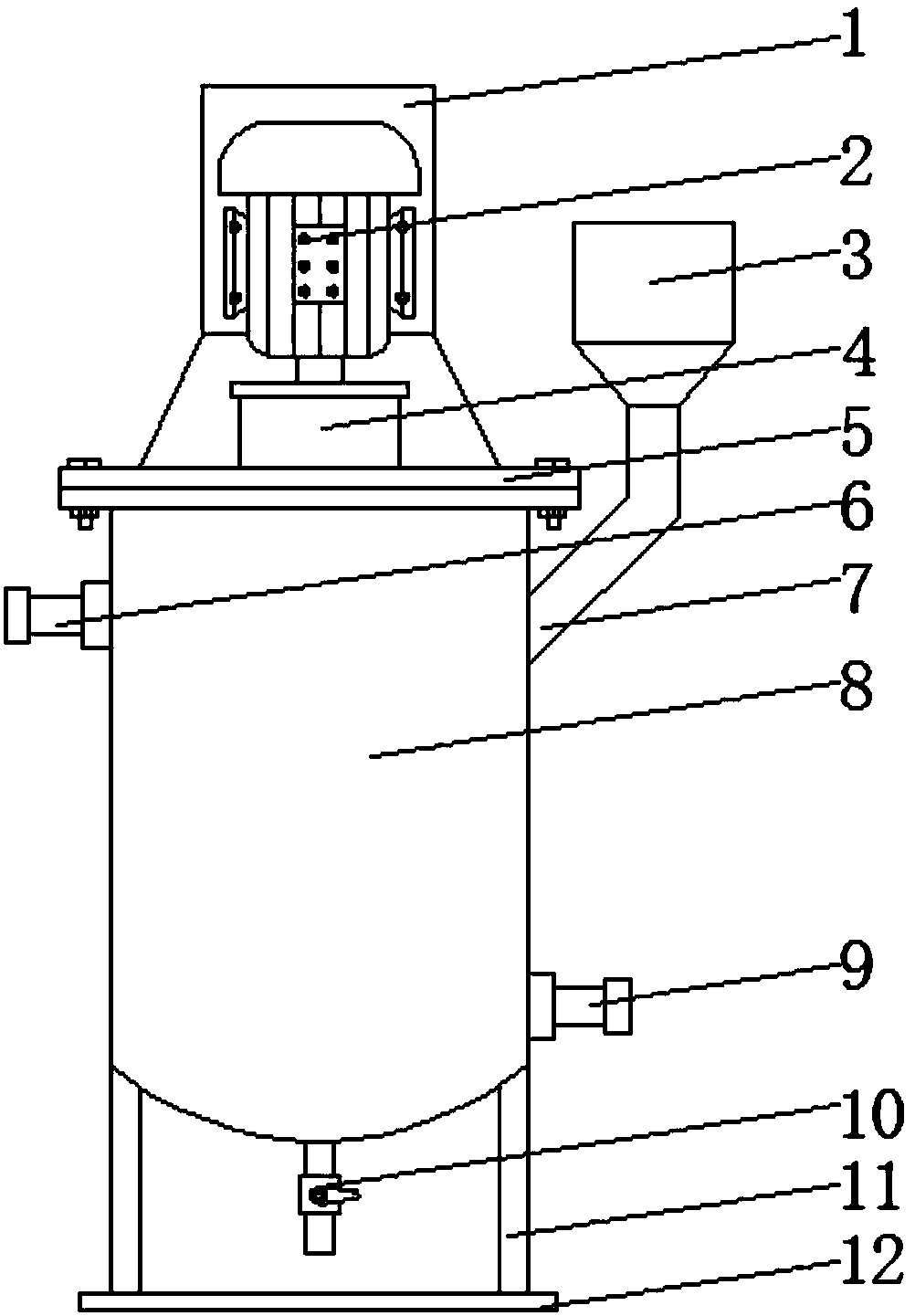

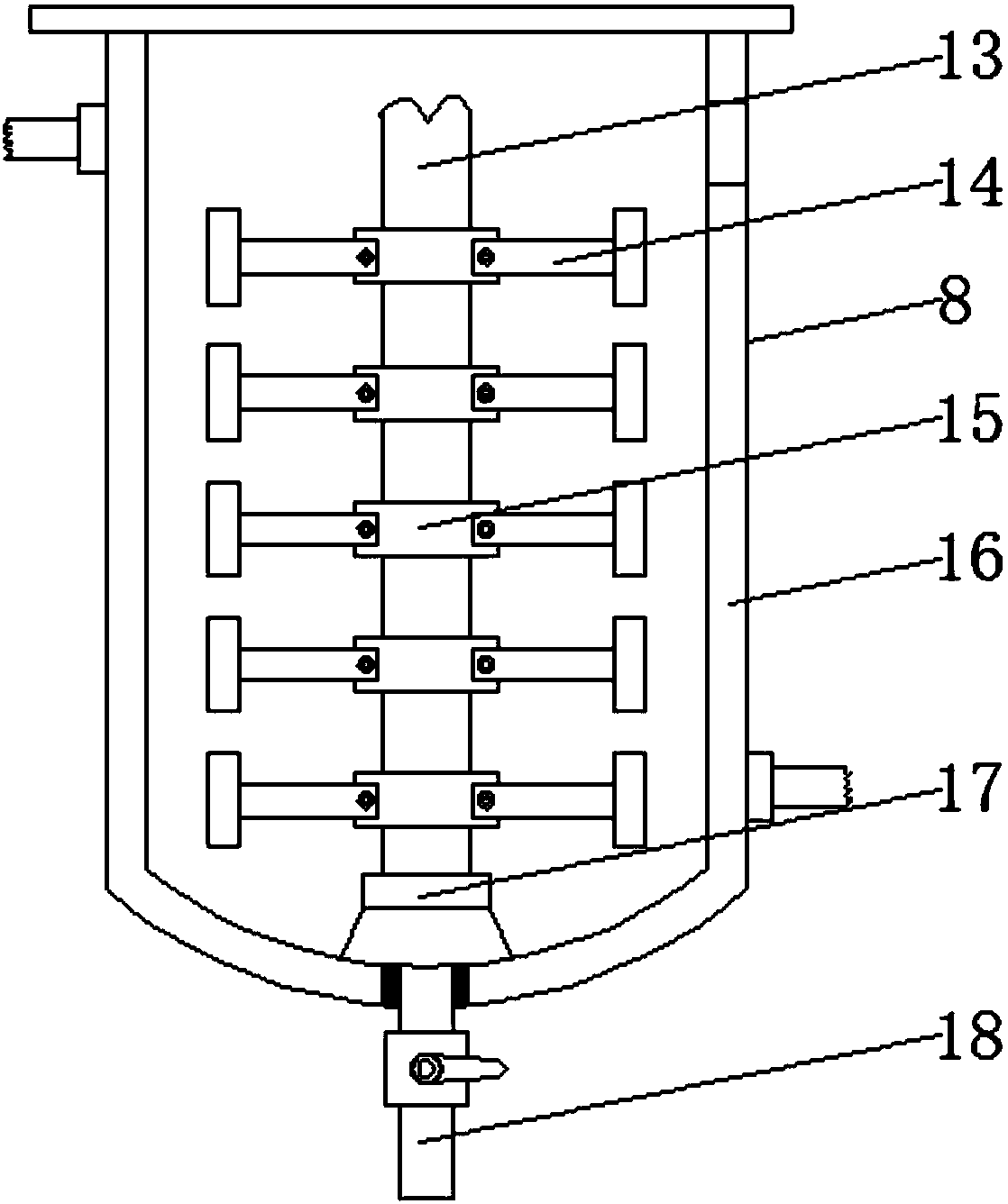

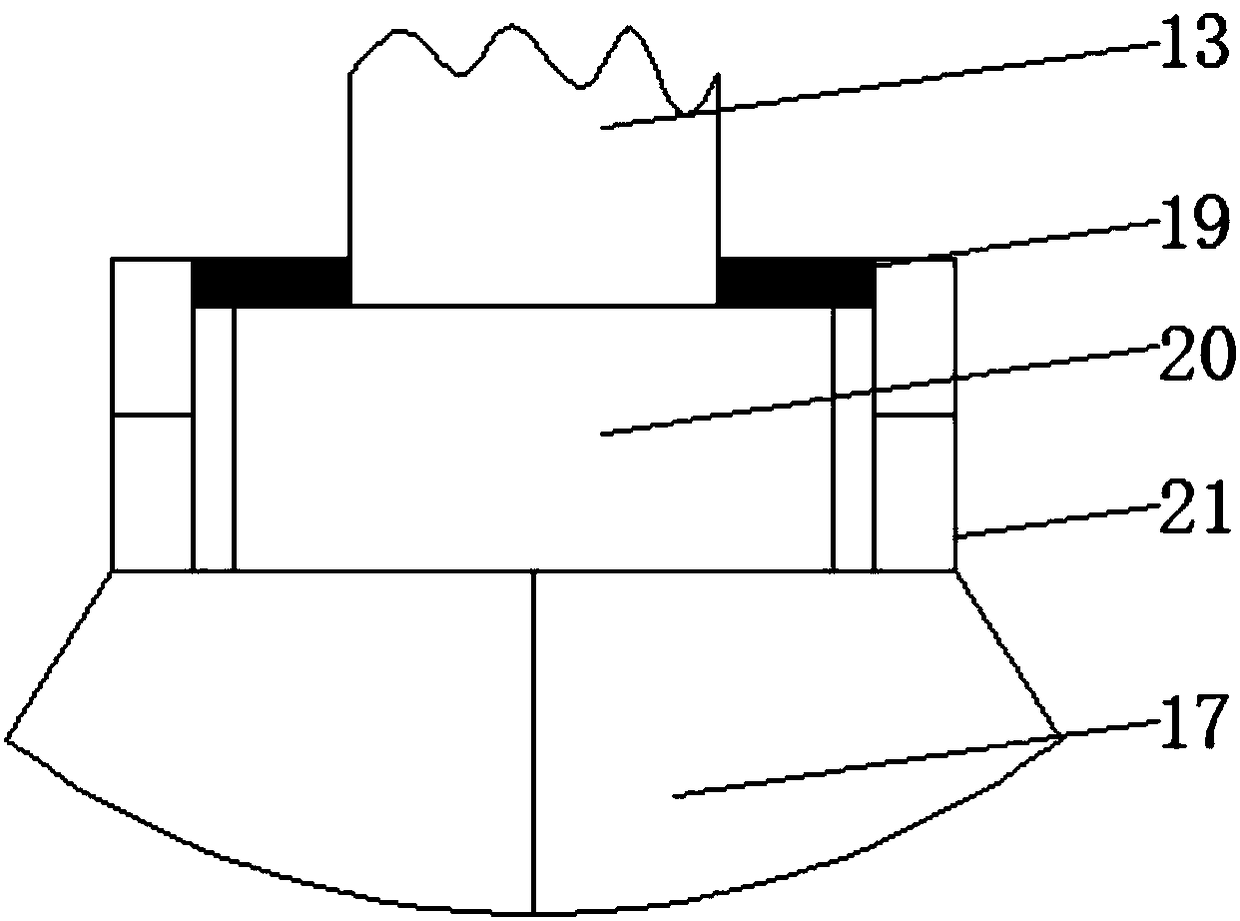

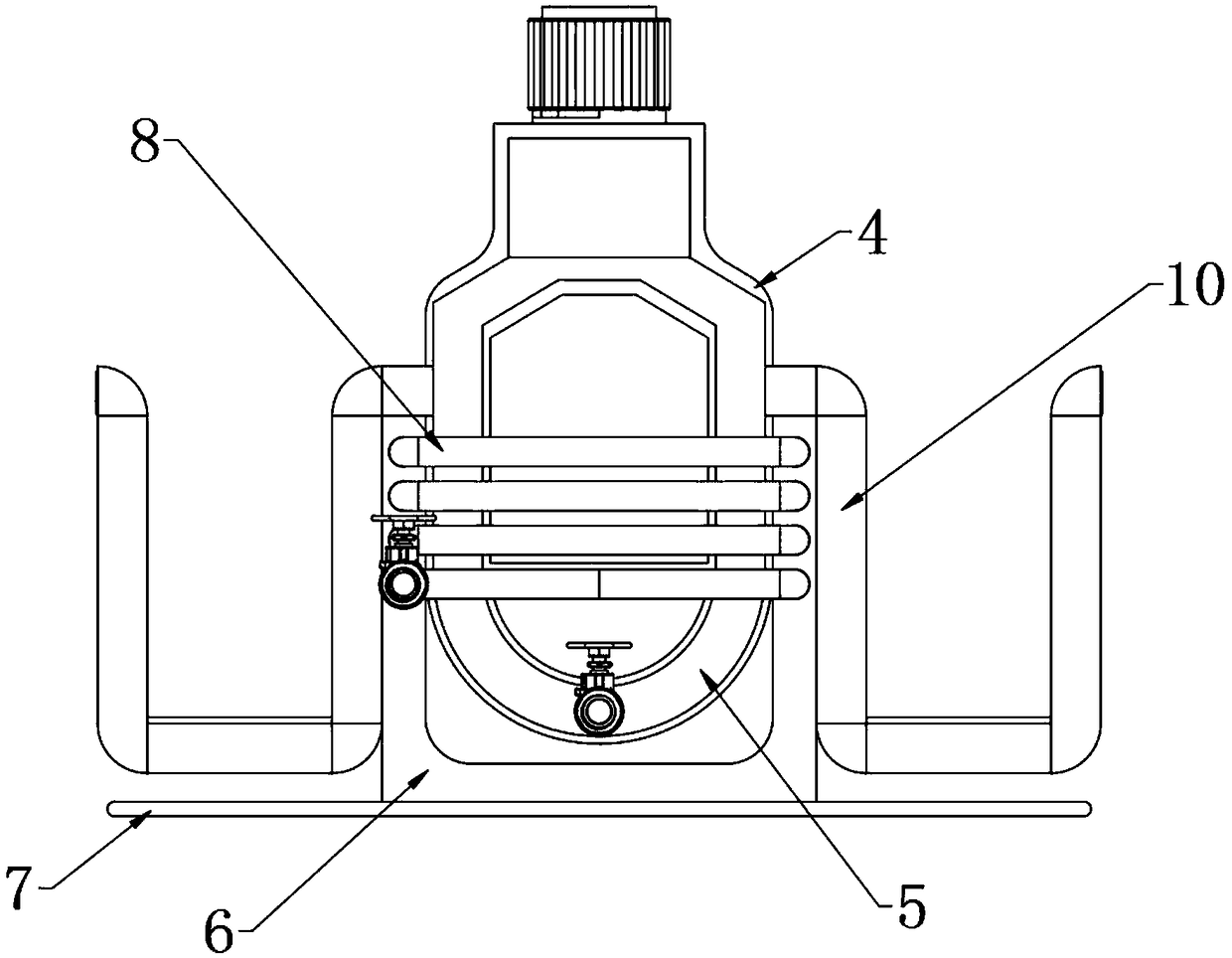

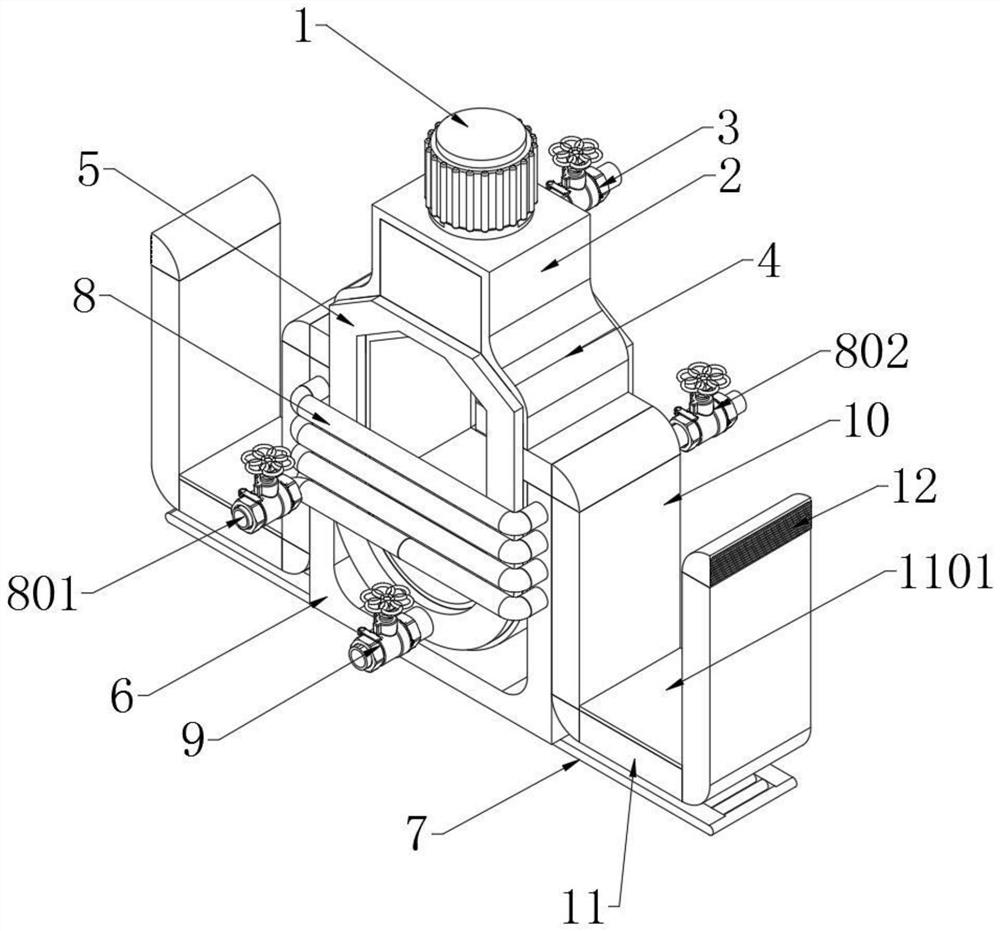

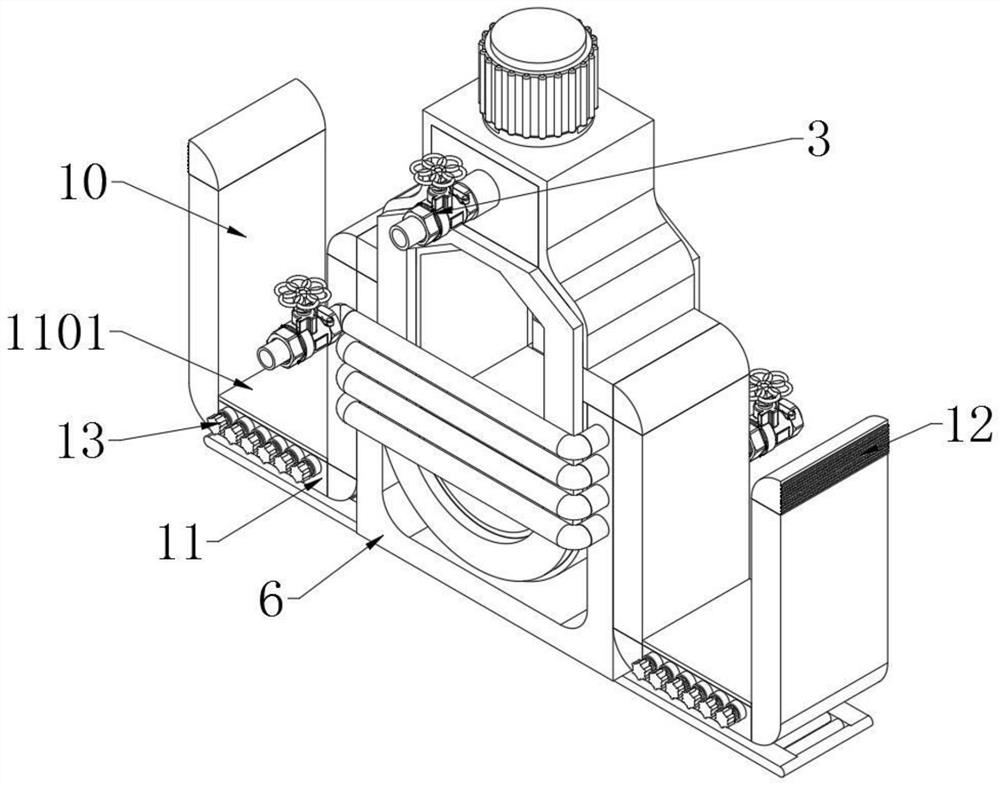

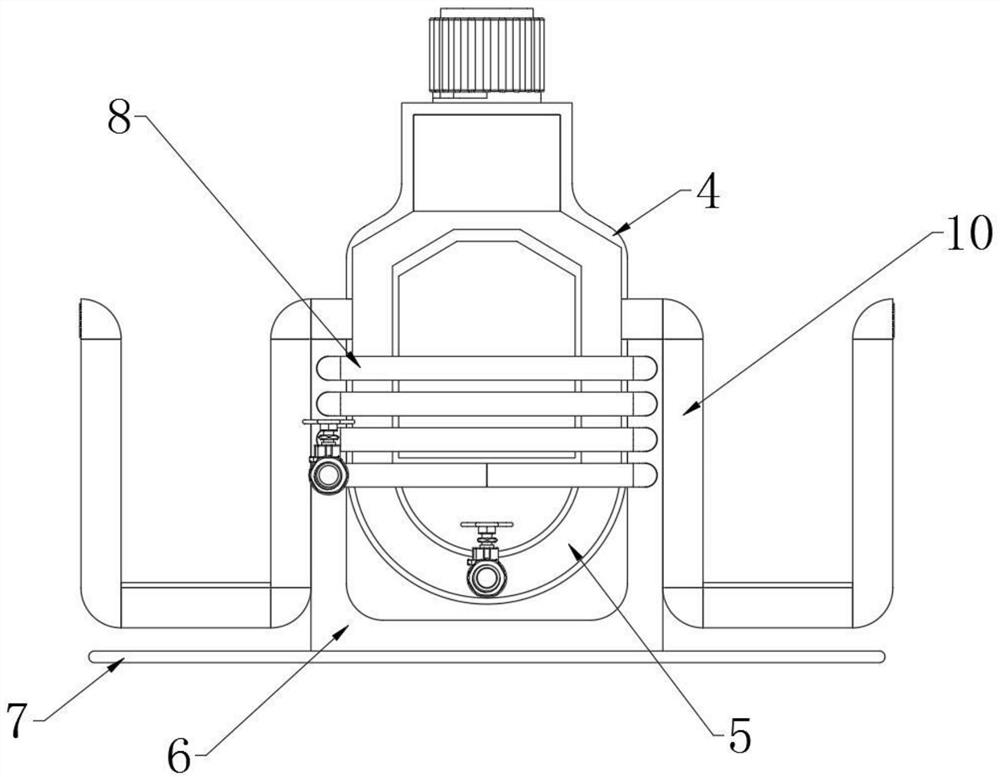

Liquefying device of rock candy

InactiveCN108531664AConducive to liquefactionRapid liquefactionSugar productsFusionEngineeringLiquefaction

The invention discloses a liquefying device of rock candy. A motor is fixed on a mounting plate by bolts; the bottom end of the mounting plate is fixedly connected with an upper cover plate; an outputshaft of the motor is fixedly connected with a main shaft through a speed reducer; supporting legs are fixed at the bottom end of a tank body; the tank body is connected with one end of a material pipe in a sealing manner; an outlet pipe is connected to the upper end of the left side of the tank body in a sealing manner; a draining pipe is connected to the bottom end of the tank body in a sealingmanner; mounting bases are fixed on the main shaft; the section shapes of paddles are T-shaped; the bottom end of the base is fixedly connected with the inner wall of the bottom end of the tank body;a bearing block is fixed inside a casing; the main shaft is fixedly connected with an inner ring of the bearing block; a sealing gasket is arranged at a connected part of the main shaft and the casing and is arranged at the upper end of the bearing block. According to the liquefying device for the rock candy, disclosed by the invention, a cavity which can hold a hot solution is formed inside thetank body for fully heating sugar liquor, so that rapid liquefaction of the sugar liquor is facilitated.

Owner:王亮

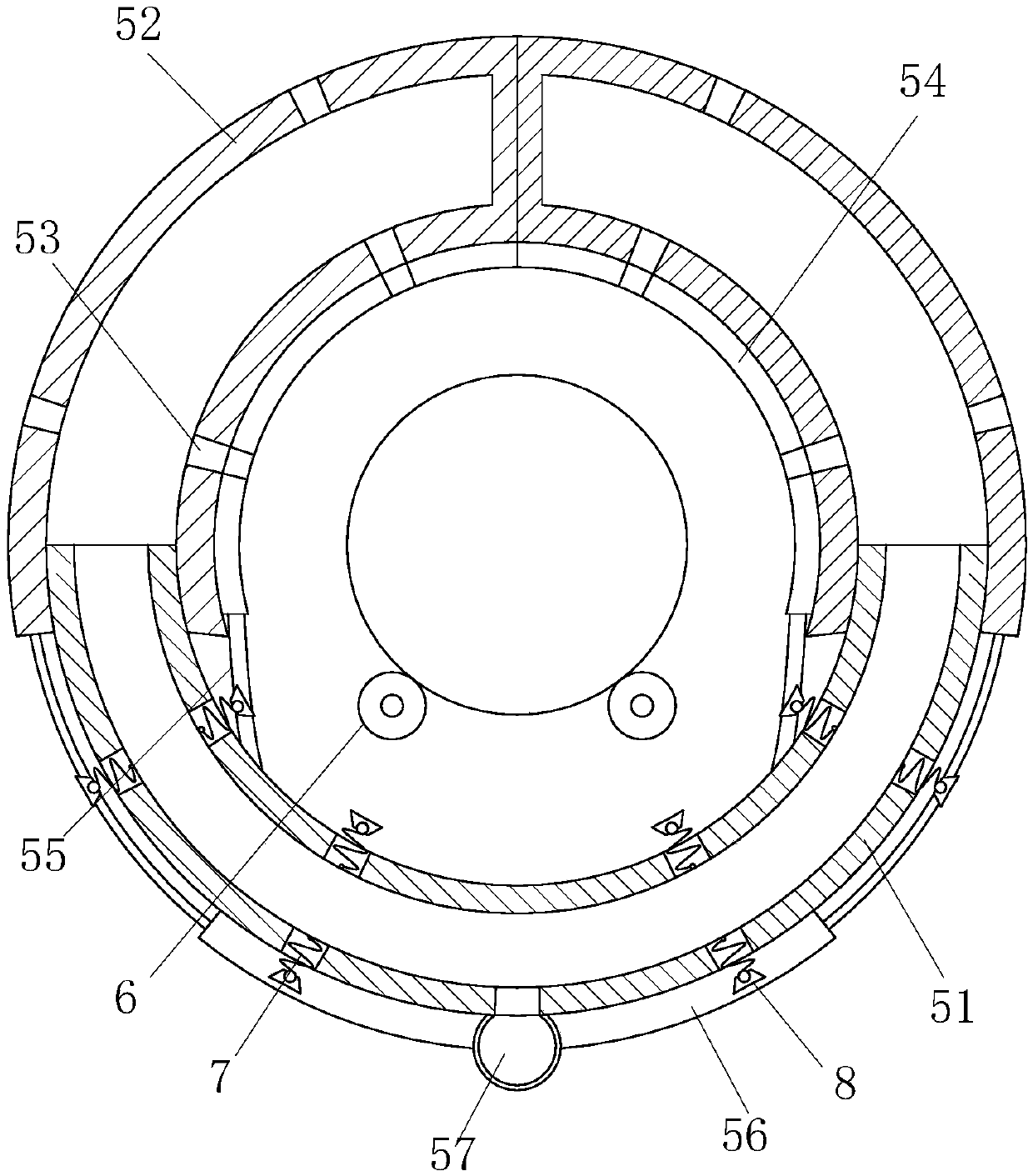

Oil mist environment test box exhaust gas treatment device

ActiveCN108926916AEasy to separateImprove separation efficiencyGas treatmentWeather/light/corrosion resistanceLaboratory facilityPetroleum engineering

The invention provides an oil mist environment test box exhaust gas treatment device. The device comprises a servo motor, an oil gas check body and a separating head. The lower end of the servo motoris fixedly connected to the center of the plane of the top of a rectangular oil-gas separation chamber through bolts. A rotation shaft of the servo motor is rotatingly connected to the interior of theoil-gas separation chamber through sealing bearings at the upper and lower ends and is fixedly connected to a separating paddle. The lower ends of the left end side wall and the right end side wall of the oil-gas separation chamber are respectively fixedly connected to the top end of an oil collector. Through cooperation of the above structures, the device can reasonably treat tail gas after thetest and reduce the oil and gas damage to the laboratory environment and the experimental personnel.

Owner:嘉兴金旅燕科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com