Organic hazardous waste thermocatalytic efficient reduction double-kettle process equipment

A technology of hazardous waste heat catalysis and process equipment, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc., can solve the problem of unreasonable energy optimization structure, unreasonable utilization of residual pressure and waste heat, and inability to Continuous processing and other issues to achieve good heat preservation effect, save energy consumption, reduce reaction temperature and reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

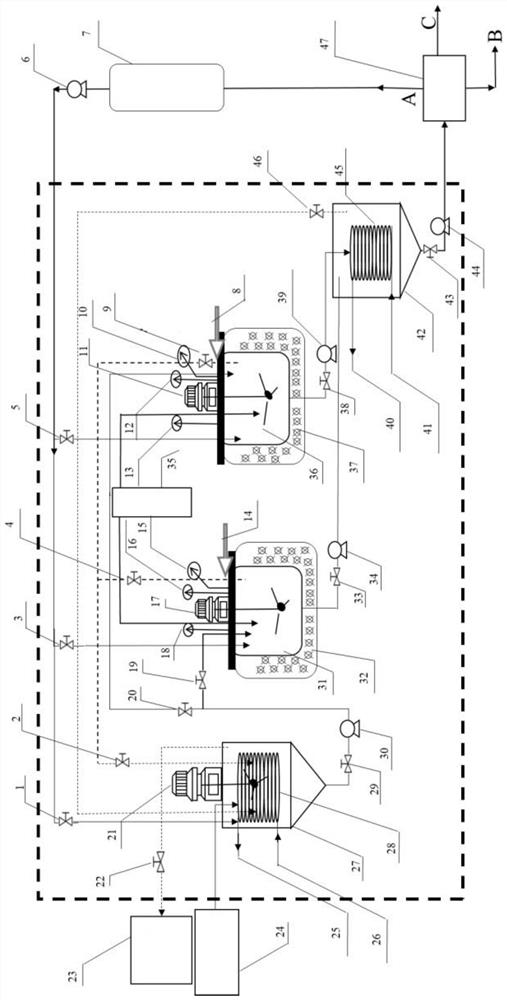

[0027] like figure 1 As mentioned above, a double-tank process equipment for organic hazardous waste thermal catalysis and high-efficiency reduction provided in this embodiment includes a batching kettle 27 connected to a material inlet and an organic waste feeding system 24, and the material outlets of the batching kettle 27 are respectively connected to the main reaction Still one 31 and main reactor two 36, the material outlet of main reactor one 31, main reactor two 36 is connected the material inlet of cooling kettle 42, and the material outlet of cooling kettle 42 is connected solid-liquid separation system 47; Main reactor one 31 The steam inlet of main reactor two 36 is connected with the outlet of steam system 35; the steam outlet of main reactor one 31 is connected with the steam inlet of batching kettle 27 and the steam inlet of main reactor two 36; the steam outlet of main reactor two 36 Connect the steam inlet of the batching kettle 27 and the steam inlet of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com