Casting of metals

A metal and light metal technology, applied in the field of light metal, can solve the problems of casting parts quality impact, air inclusions in alloys, etc., achieve high alloy diversity, avoid multiple melting, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

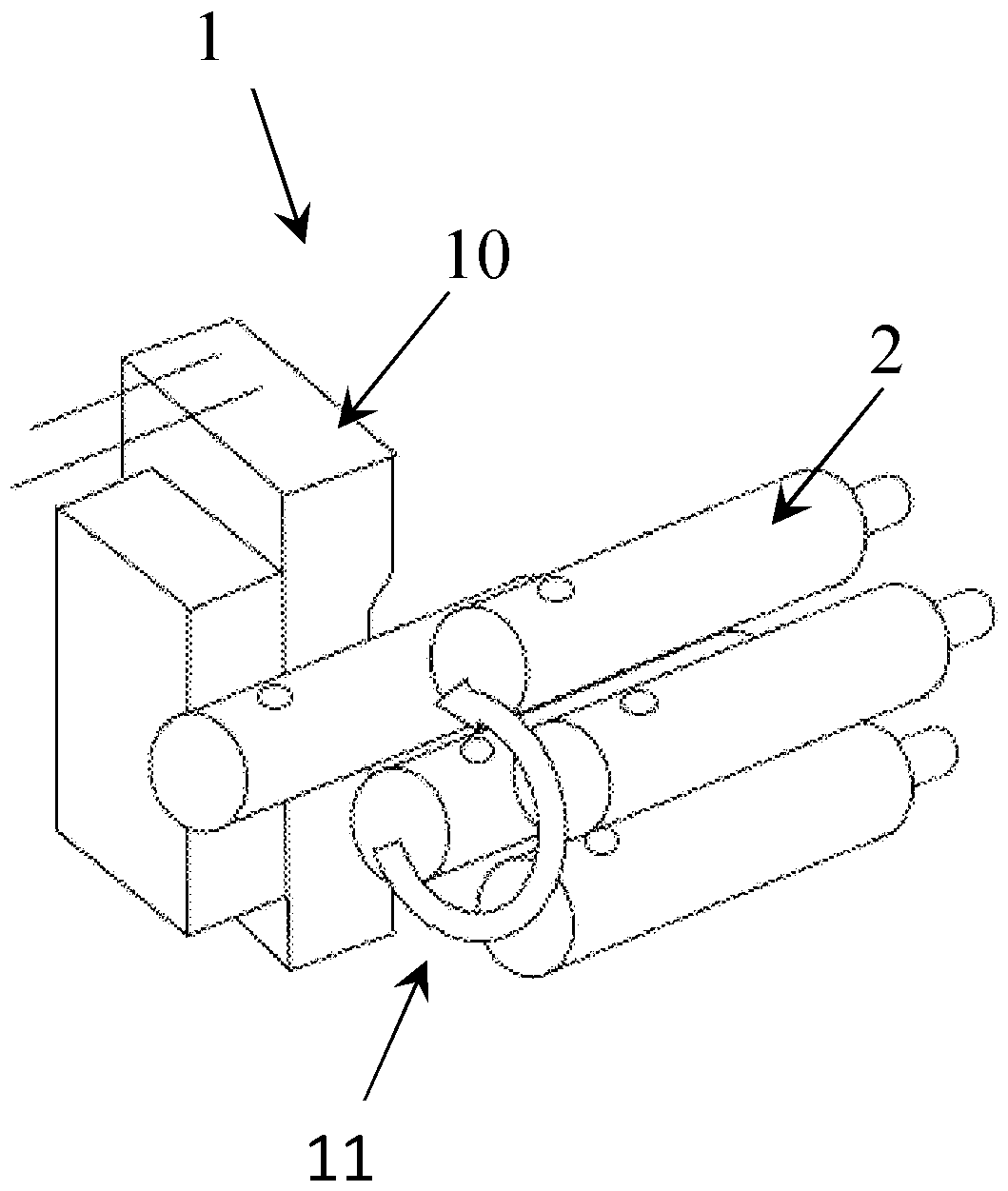

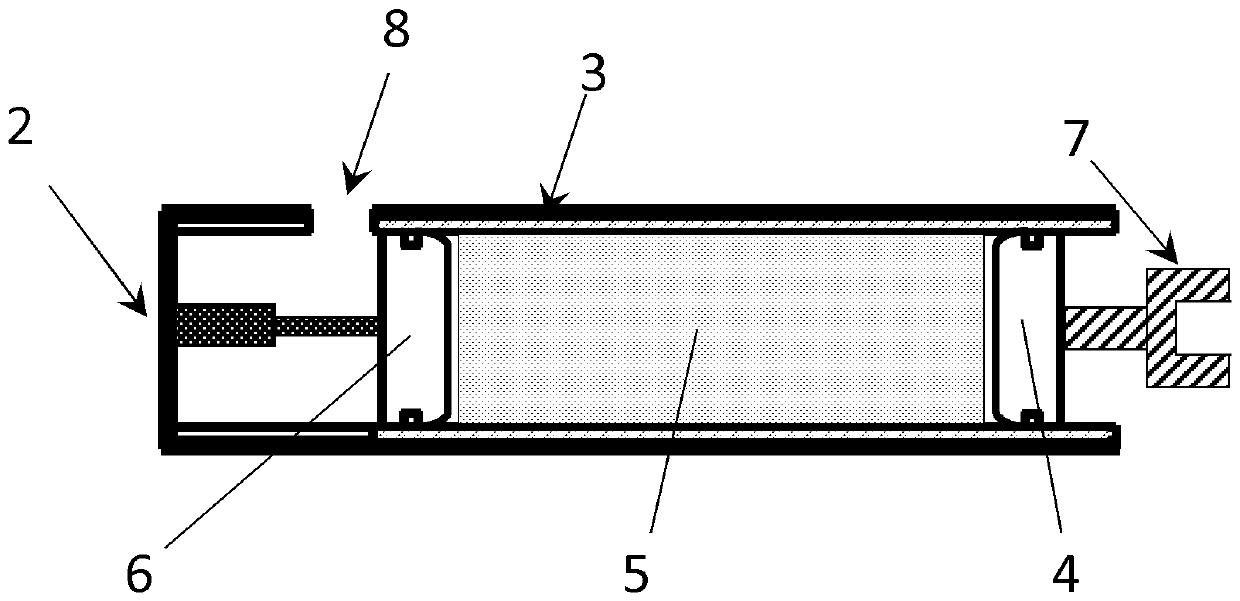

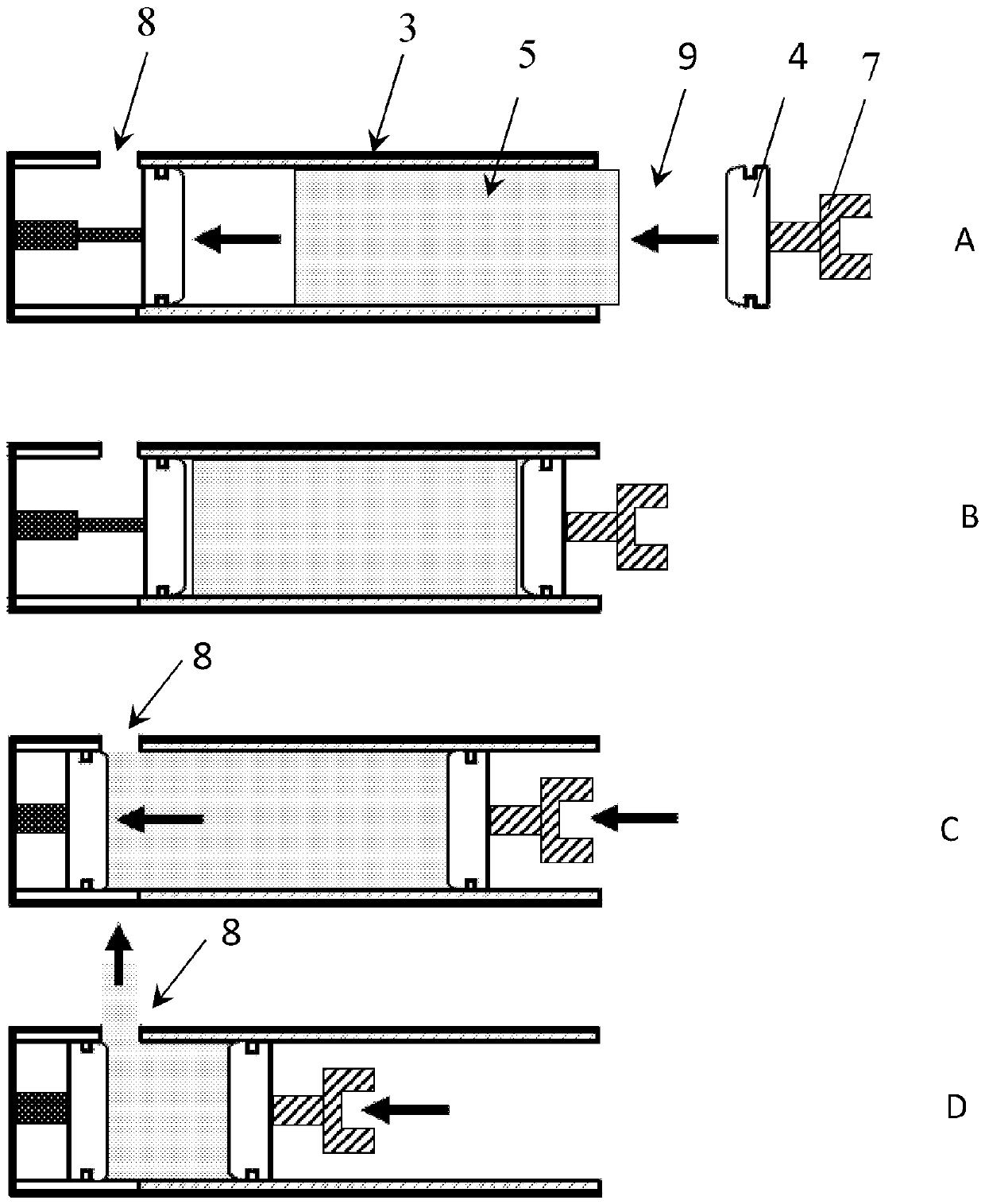

[0043] figure 1 The shown figure shows the casting chamber 2 of the device 1 according to the invention, the metal rod 5 to be cast has been placed and the casting chamber 2 is completely closed. Arranged along the circumference of the casting chamber 2 are induction heating elements 3 which preferably extend over the length of the casting chamber 2 in order to ensure uniform heating of the bar 5 . It can be clearly seen that almost 100% filling of the casting chamber 2 can be achieved by introducing the metal to be cast as a solid, which helps to reduce air inclusions in the cast part. In the casting chamber 2 of the device 1 according to the invention, rods are placed into the casting chamber 2 through the inlet opening 9, as figure 2shown. Subsequently, the casting piston 4 is moved up to the bar 5 and the closure system 6 keeps the outlet opening 8 closed so that the casting chamber is completely closed. A closing piston is preferably used as the closing system 6, alth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com