Steam spray degreasing device

A generator and spout technology, applied in the field of kitchen stoves, can solve the problems of difficult cleaning, reduce the working pressure and heavy workload of the oil filter device, and achieve the effects of reducing working pressure, enhancing the effect of degreasing, and increasing the working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

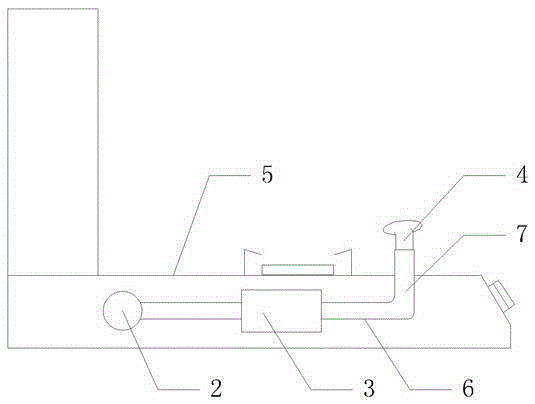

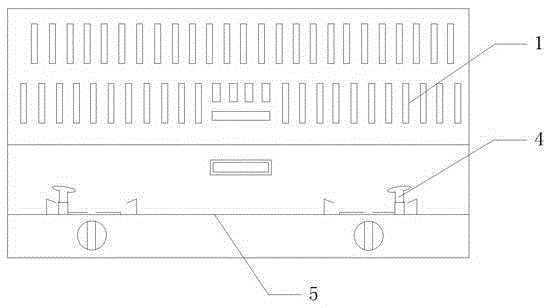

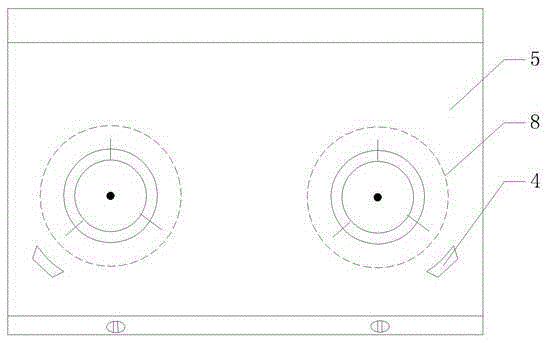

[0022] Such as Figure 1-4 As shown, a steam jet degreasing device is mainly used on side absorption range hoods, and it includes a fan 2, a water vapor generating device 3 and a steam delivery nozzle 4 connected in sequence, wherein the fan 2 and the water vapor generating device 3 are both set Below the cooktop 5, the steam delivery nozzle 4 is arranged above the cooktop 5 at the front of the cooktop, and is connected to the water vapor generator through the vertical steam supply pipe 7 above the cooktop 5 and the horizontal steam supply pipe 6 below the cooktop 5. Device 3, the steam delivery nozzle 4 is provided with a flat tongue-shaped spout 41 for spraying water vapor. Jetting out, the steam injection direction of the nozzle 41 is to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com