Device for achieving thermocatalytic efficient reduction and reclamation of organic wastes

A technology of organic waste and thermal catalysis, applied in chemical instruments and methods, heating water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of environmental secondary pollution, high cost, secondary pollution, etc., and achieve Improve weight reduction effect, reduce reaction time, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with specific embodiment, further illustrate the present invention.

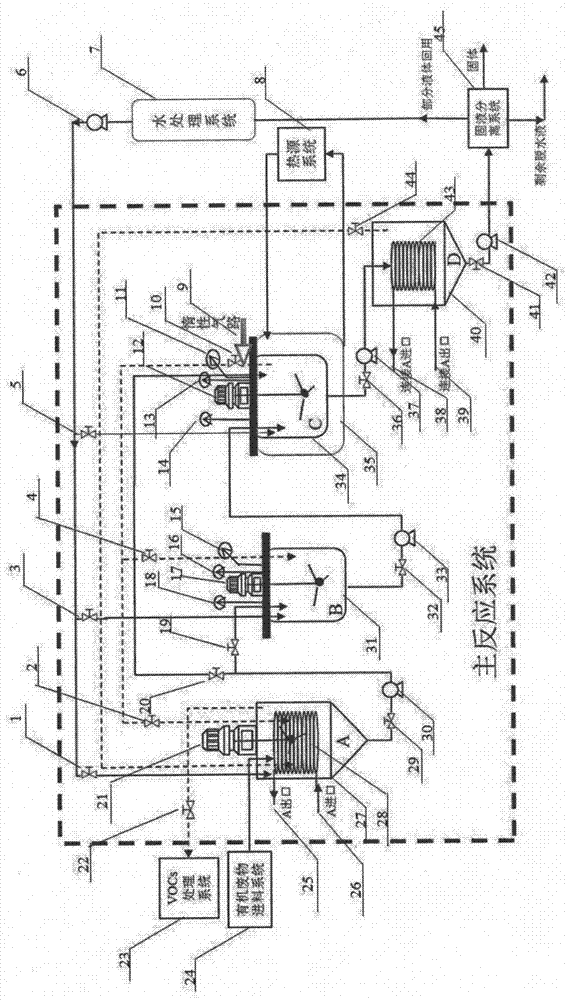

[0040] figure 1 The structural schematic diagram of the device for realizing the efficient thermal catalysis reduction and recycling of organic waste provided in this embodiment, the device for realizing the efficient thermal catalysis reduction and recycling of organic waste includes an organic waste feeding system 24, an organic waste feeding The system 24 is connected to the material inlet of the batching kettle A27 through a pipeline, and transports the organic waste and the organic catalyst to the batching kettle A27 respectively. The batching kettle A27 is provided with a stirring motor 21, and the stirring motor 21 is turned on, and the organic waste and the organic catalyst are configured into uniformly mixed reaction materials.

[0041] The material outlet of the batching kettle A27 is connected to the material inlet of the main reaction kettle C34 through a pipeline. A f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com