Modified sludge-based hydrothermal carbon and application of modified sludge-based hydrothermal carbon in incineration of dewatered sludge

A hydrothermal carbon and sludge technology, applied in the fields of resources, environment and energy utilization, can solve the problems of increasing the wear and tear of the flue gas treatment system, restricting the development of sludge incineration technology, reducing the thermal efficiency of the incinerator, etc., and achieving a reduction in the moisture content of the sludge , promote the hydrothermal liquefaction reaction, improve the effect of flocculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: preparation of chitosan grafted polyacrylamide (Chi-g-PAM)

[0034] Step S1, using an oil bath to maintain a constant temperature of 40°C, stirring and adding 3 g of chitosan into 150 mL of 1w / v% acetic acid aqueous solution in a light-proof Erlenmeyer flask, purging with nitrogen during the process;

[0035] Step S2, the solution was stirred for 30min, and 1mL of 0.058mM cerium ammonium nitrate initiator and 3mL photoinitiator (V50) were added to generate primary free radicals on the chitosan main chain, grafted with acrylamide (AM), and the initiator was pretreated 5min, inhibit the formation of PAM homopolymer;

[0036] Step S3, add 9gAM monomer while stirring so that the mass ratio of chitosan and acrylamide is 1:3, and place it in an ultraviolet-microwave induction device (microwave power: 100-1000W, frequency: 2450MHz, power supply: 1500VA, ultraviolet Wavelength range: 290nm-400nm, lamp power: 100W), the irradiation time is set to 30min, and the po...

Embodiment 2

[0039] Example 2: Preparation of modified sludge-based hydrothermal carbon, Chi-g-PAM is prepared according to the method of Example 1

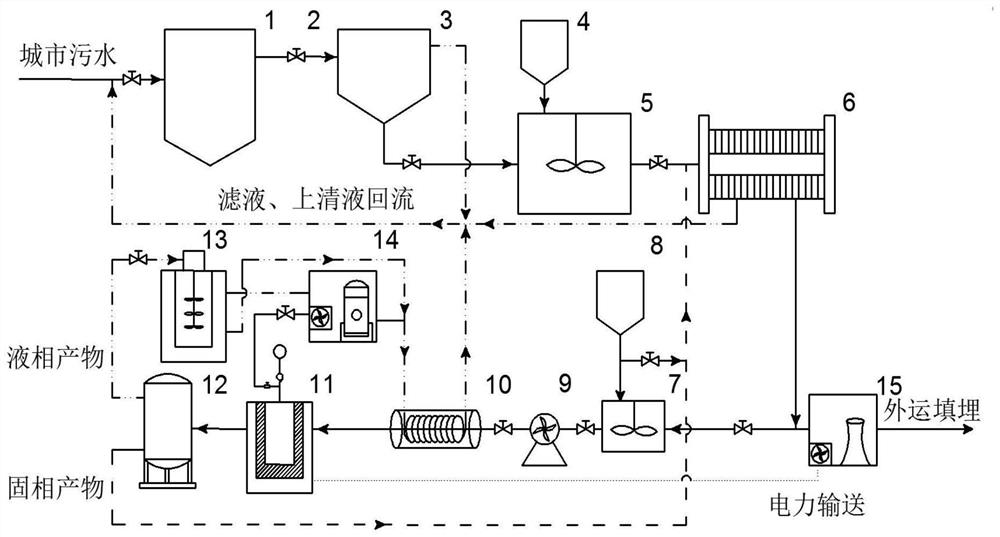

[0040] Step S1, dehydrating 10.0wt.% of the remaining sludge produced in the sludge thickening tank 3 through the plate and frame filter press 6 to obtain dewatered sludge, and the water content was determined to be 76.34wt.%.

[0041]In step S2, the dewatered sludge is mixed with Chi-g-PAM (5.0wt.%) prepared in Example 1, and then transported to the two-stage continuous hydrothermal reactor 11 through the high-pressure plunger pump 9. In the heat exchanger 10 After heating up to 85°C, enter the hydrothermal reaction zone, raise the temperature to 450°C at a rate of 15°C / min, and conduct a hydrothermal reaction for 30 minutes;

[0042] Step S3, after the hydrothermal liquefaction reaction, the mixed product is gas-collected, heat-exchanged, and cooled, and carbon tetrachloride (or ethyl acetate can also be used) is used to extract and separat...

Embodiment 3

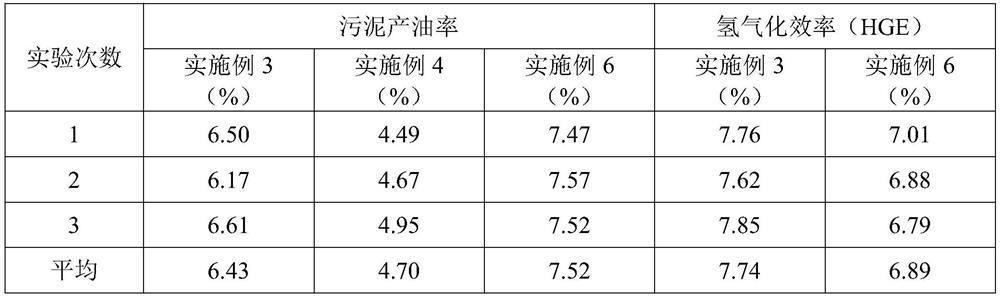

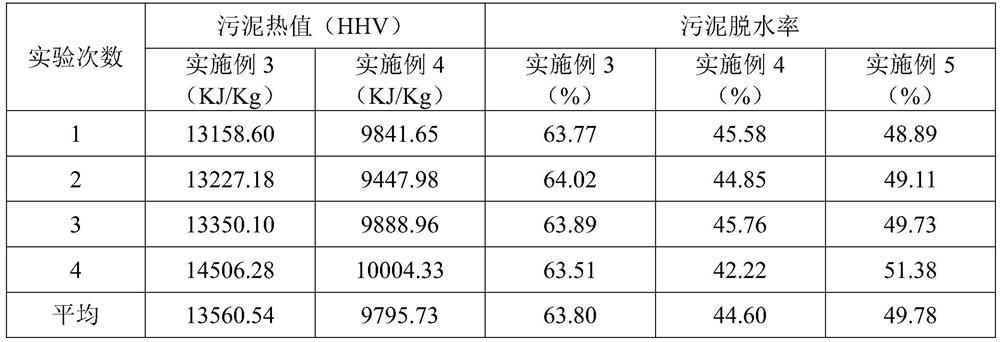

[0043] Example 3: Preparation of hydrothermal charcoal-doped sludge, wherein: Chi-g-PAM is prepared according to the method of Example 1, and modified sludge-based hydrothermal charcoal is prepared according to the method of Example 2

[0044] Step S1, uniformly dispersing the modified sludge-based hydrothermal charcoal and Chi-g-PAM in the remaining sludge produced by the initial press filtration of the plate and frame filter press 6, the moisture content of the sludge was determined to be 76.34wt.%, Chi - The addition ratio of g-PAM in the sludge is 5.0wt.%;

[0045] Step S2, the sludge to be treated is transported to the plate and frame filter press 6 through the high-pressure plunger pump 9, and hydrothermal carbon-doped sludge is obtained after pressure filtration, liquid-solid separation, and slag unloading.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com