Device and method for recycling nitrogen of annealing furnace

An annealing furnace and nitrogen technology, which is applied in the field of nitrogen reuse devices in annealing furnaces, can solve the problems of oil pollution of workpieces and nitrogen waste, and achieve the effects of reducing exhaust gas emissions, saving economy and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

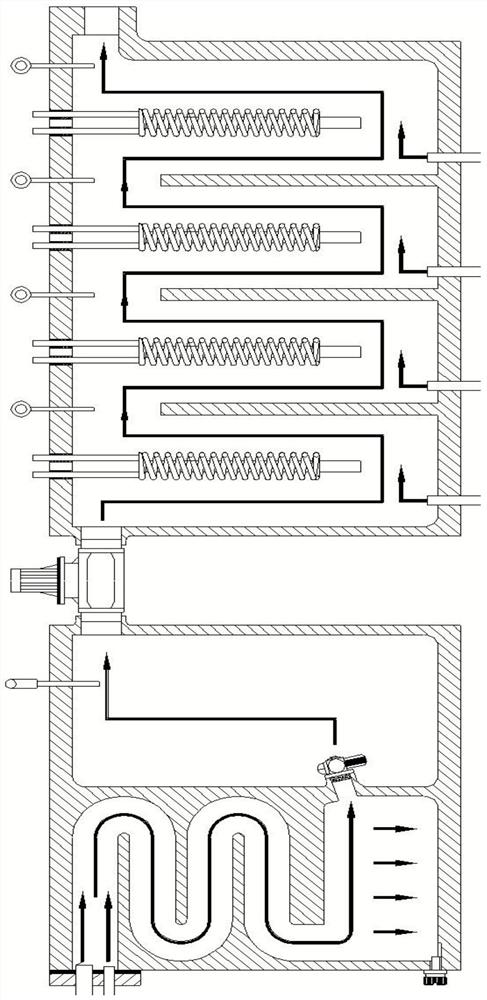

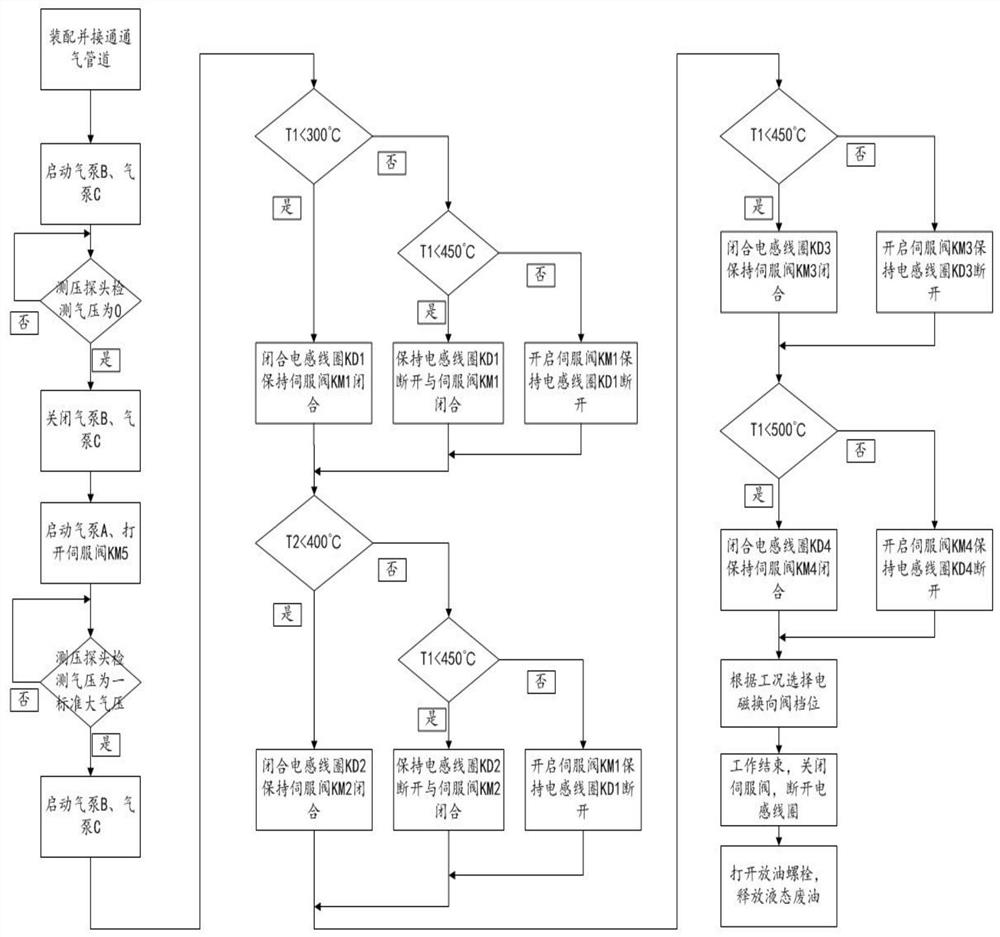

[0046] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

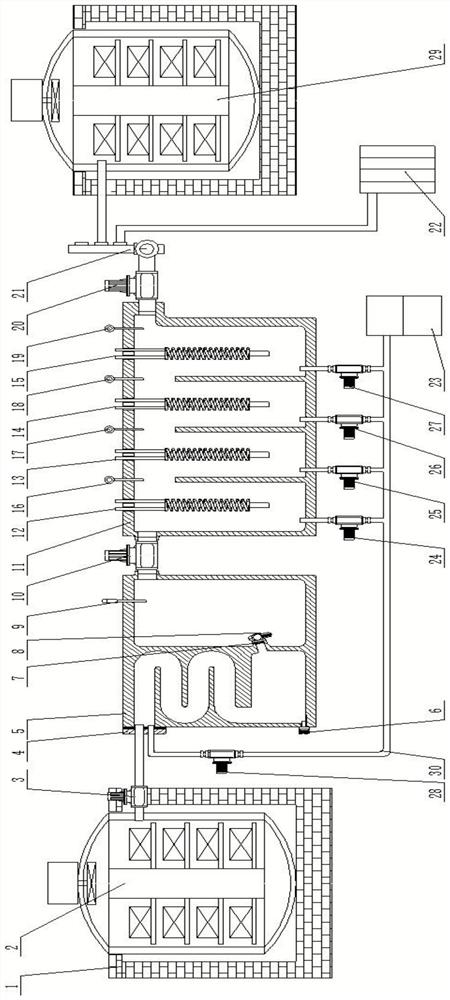

[0047] The invention provides a device for recycling nitrogen in an annealing furnace, such as Figure 1-Figure 3 As shown, the device of the present invention mainly includes an annealing furnace assembly, a condensation tank assembly, a temperature control tank assembly and a pipeline assembly.

[0048] The annealing furnace assembly includes a heat preservation foundation 1 , a pre-release nitrogen annealing furnace 2 and a pre-release nitrogen annealing furnace 29 , and both the pre-release nitrogen annealing furnace 2 and the pre-flow nitrogen annealing furnace 29 are placed in the heat preservation foundation 1 .

[0049] The condensation tank assembly includes a condensation tank 5, a sealing plate 4, an oil drain bolt 6, an oil filter 7, an air source filter 8 and a pressure measuring probe 9. The upper part of the first side of the condensation tank 5 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com