Oil mist environmental test chamber exhaust gas treatment device

An environmental test chamber and tail gas treatment technology, applied in gas treatment, measuring devices, weather resistance/light resistance/corrosion resistance, etc., can solve problems such as physical health damage of experimenters, and achieve the effect of improving efficiency and increasing travel paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

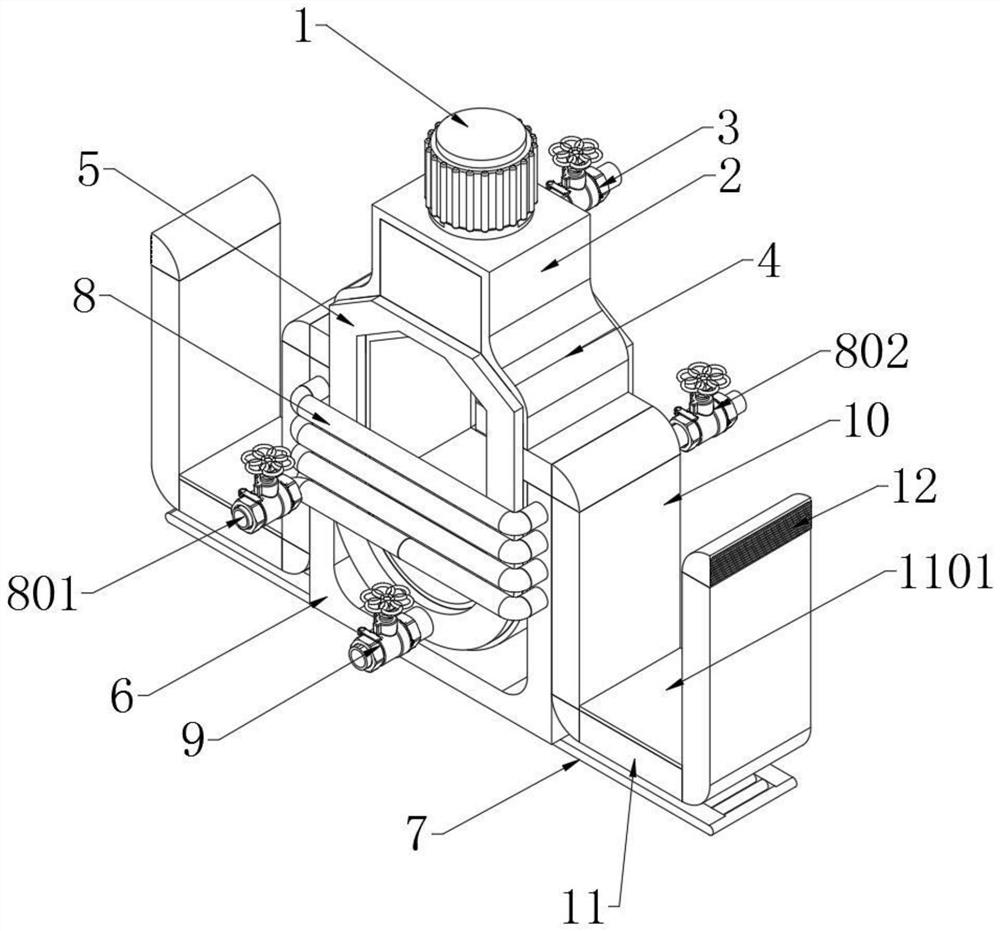

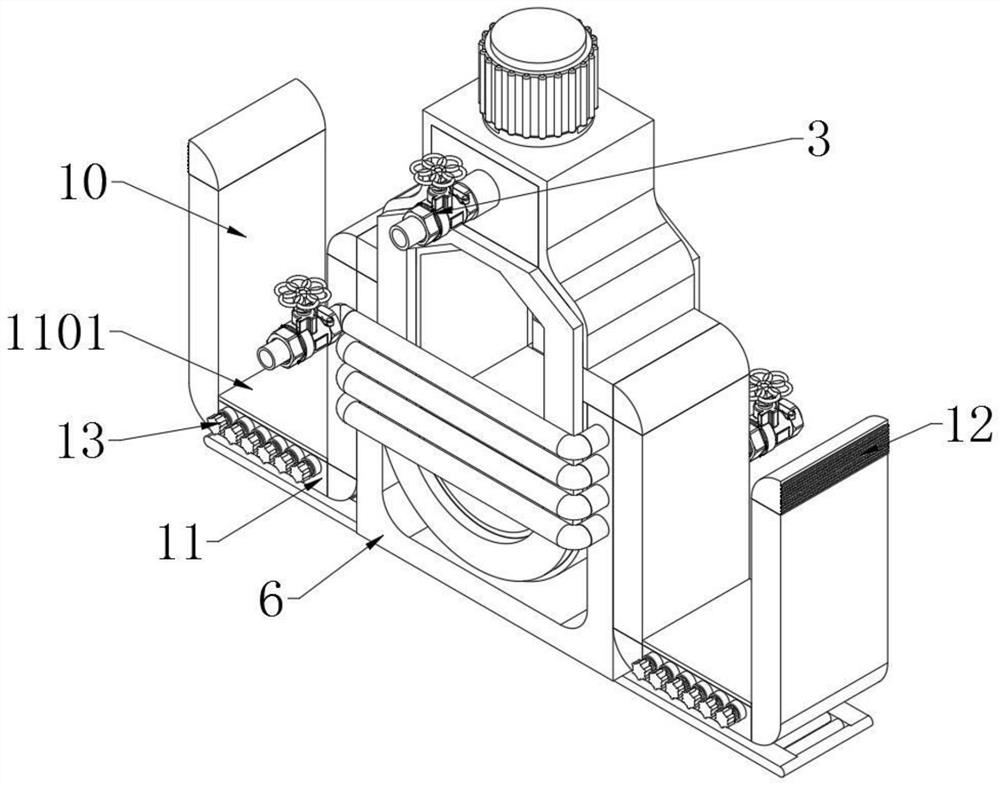

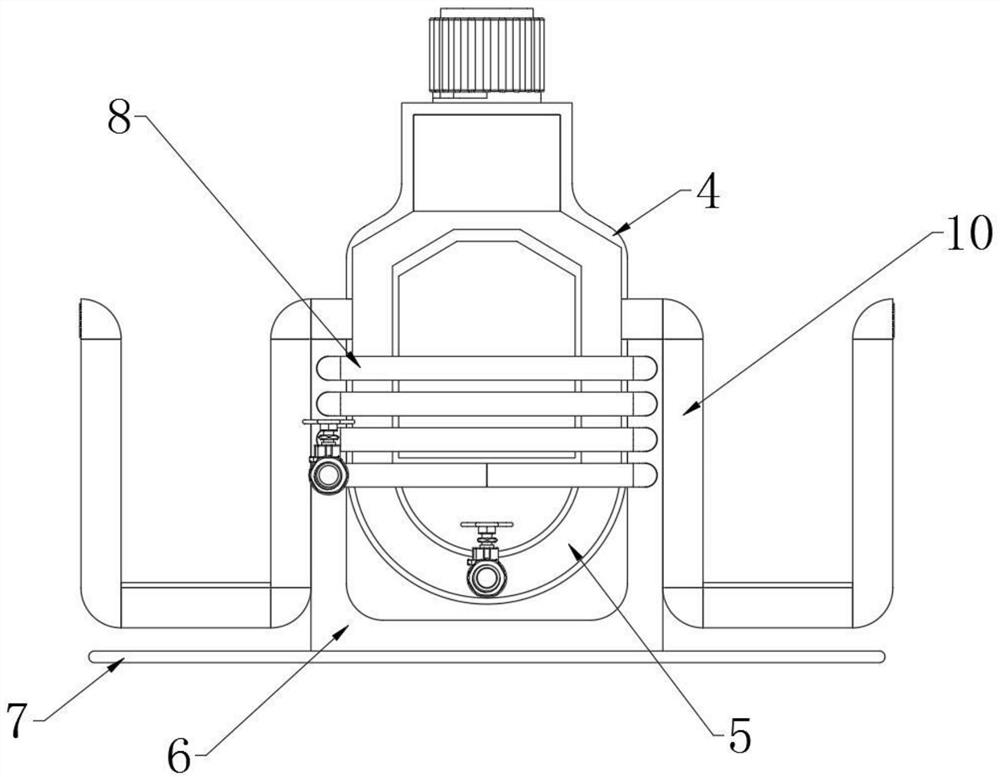

[0035] as attached figure 1 to attach Figure 10 Shown:

[0036]The invention provides an exhaust gas treatment device for an oil mist environmental test chamber, which includes a servo motor 1, an oil and gas separation chamber 2, an oil mist exhaust inlet pipe 3, an oil collecting body 4, a sealing cover 5, a support body 6, a base 7, a condensation pipe 8, and an inlet Water port 801, drain port 802, oil discharge pipe 9, odor purification pipeline 10, odor purification box 11, top cover 1101, socket slot 1102, air purification outlet 12, odor purification stick 13, separation paddle 14, sealed bearing 1401, Diverter 15, primary air discharge head 16, air intake port 1601, air intake hole 1602, oil and gas non-return body 17 and separation head 1701; the lower end of the servo motor 1 is fixedly connected to the top of the rectangular parallelepiped oil and gas separation chamber 2 by bolts In the center of the plane, the rotating shaft of the servo motor 1 is rotatably c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com