Integrated afterburner with double oil circuits and truncated central cone structure

A technology of afterburner and double oil circuit, which is applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., and can solve the problems of reduced combustion efficiency, high gas temperature, and low pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described now in conjunction with accompanying drawing:

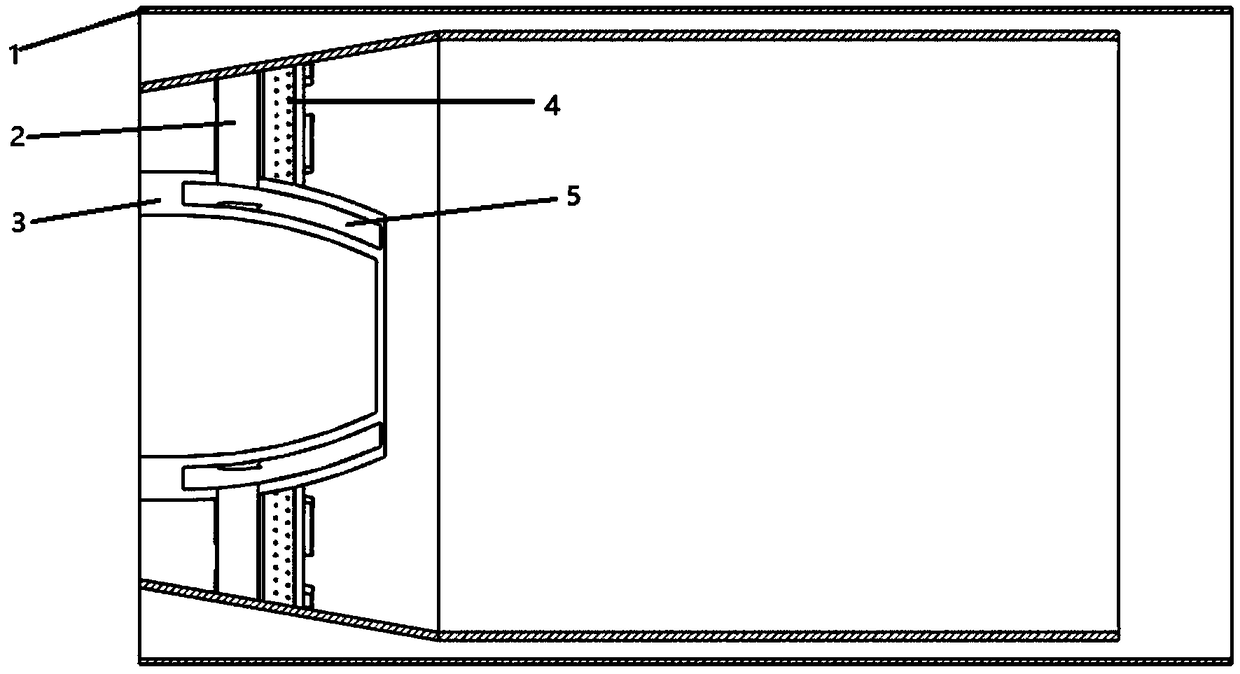

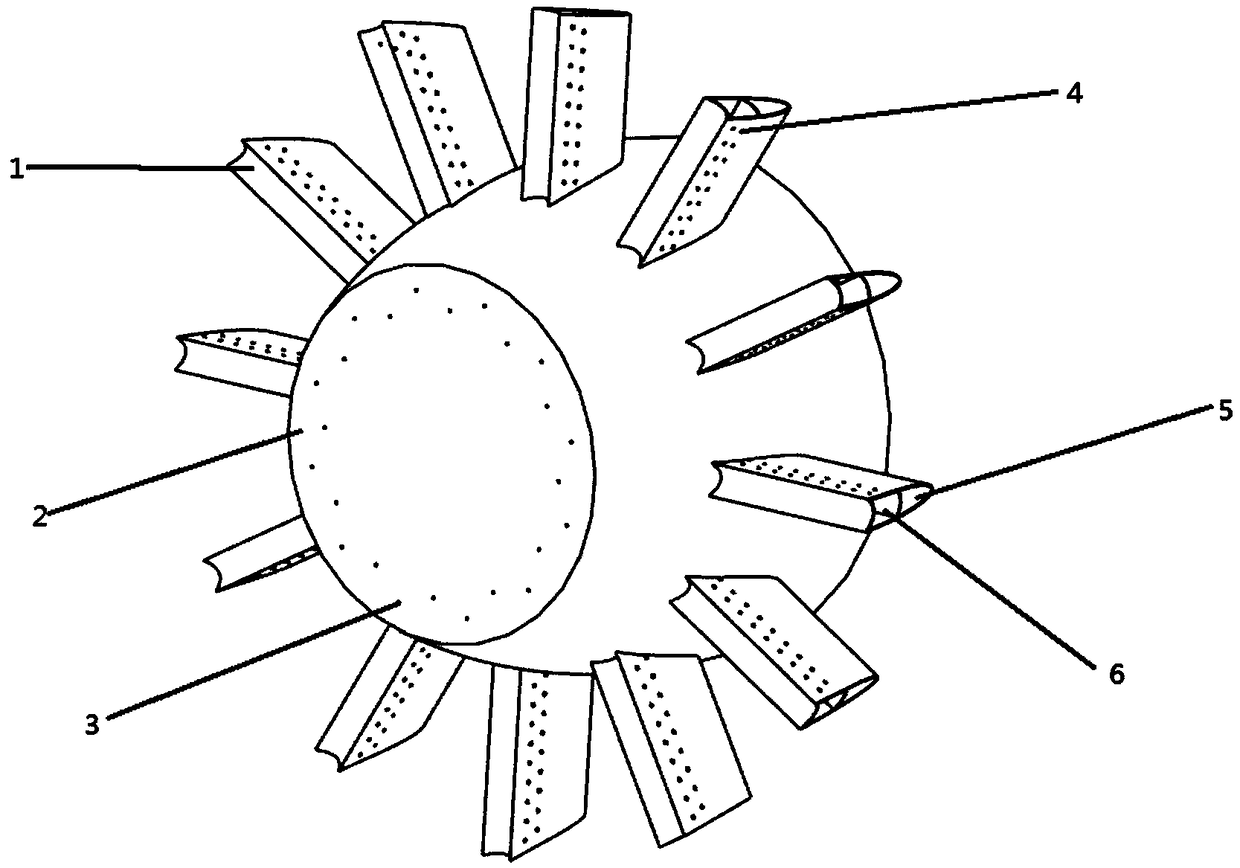

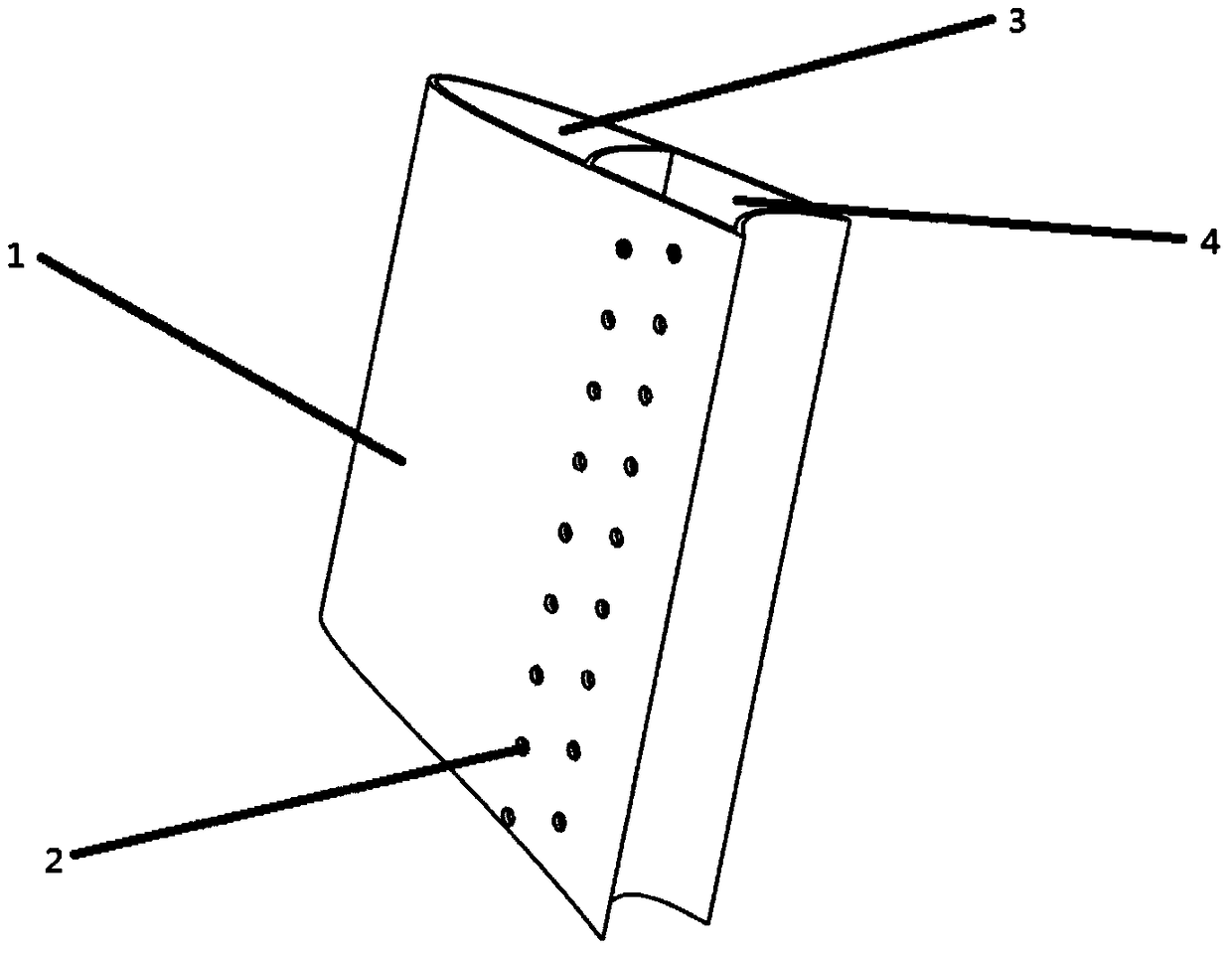

[0017] combine figure 1 , figure 2 , image 3 , The invention provides an integrated afterburner with double oil passages and truncated central cone structure. figure 1 It is an overall schematic diagram of an integrated afterburner with double oil passages and truncated central cone structure, figure 2 It is a schematic diagram of an integrated afterburner head with double oil passages and truncated central cone structure, image 3 It is a schematic diagram of the rectifying strut flame stabilizer structure.

[0018] The airflow from the inner and outer ducts is mixed between the blades of the straightening support plate flame stabilizer through the sliding baffle type rear duct ejector, figure 1 (2) The rectifying support plate flame stabilizers shown in (2) are uniformly arranged in the circumferential direction. The fuel oil is divided into two streams and enters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com