Analysis method for trace oxalic acid root in mother liquor of plutonium oxalate precipitation

A technology for precipitating mother liquor and analysis methods, applied in the direction of analysis materials, measuring devices, material separation, etc., can solve the problems of nitric acid interference, analysis time extension, etc., to avoid measurement interference, analysis time extension, high sensitivity and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

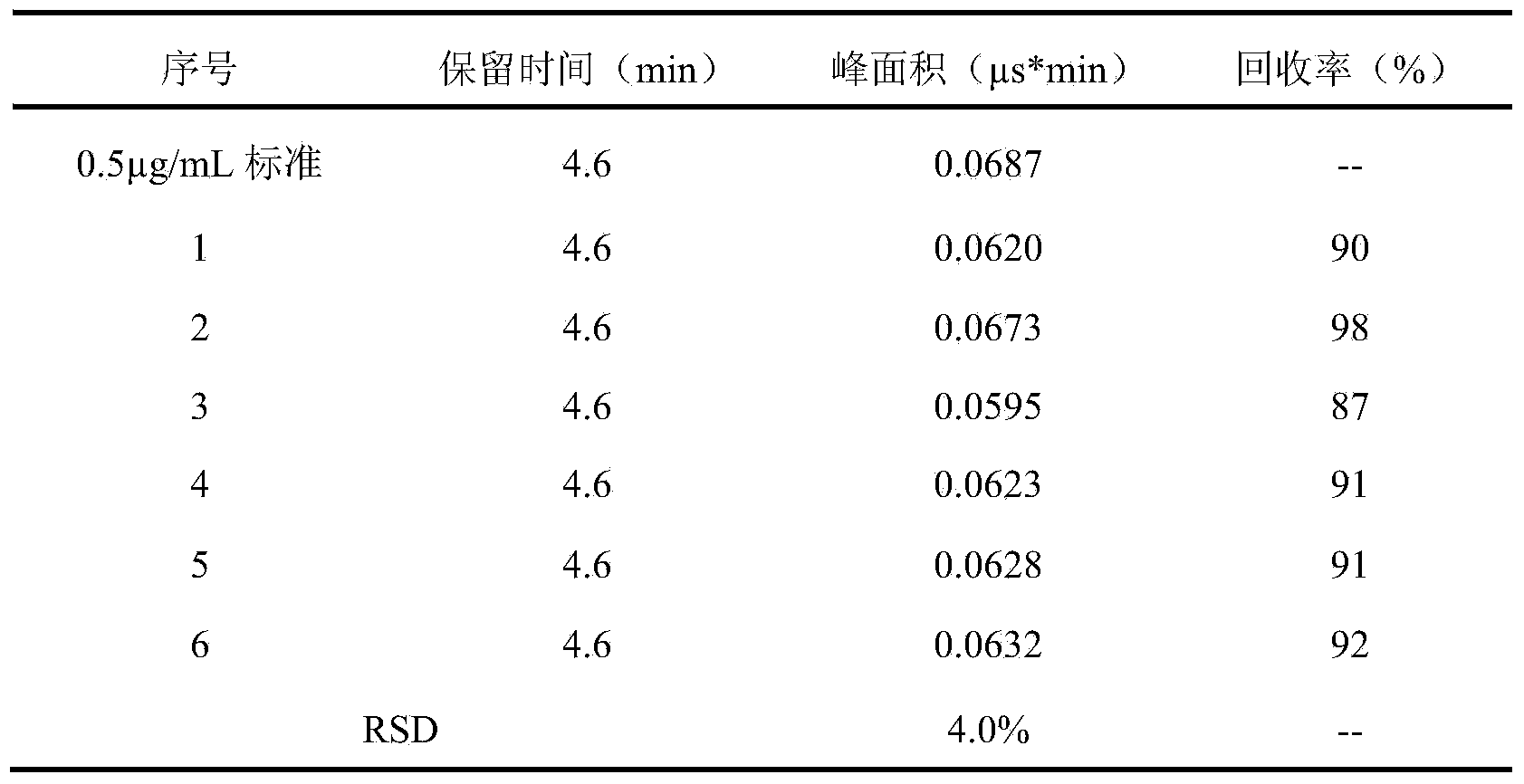

Examples

Embodiment 1

[0028] The analysis method of trace oxalate in the plutonium oxalate precipitation mother liquor, this method is to utilize chromatography to measure the oxalate content, and concrete steps are:

[0029] (1) Take a certain volume of 0.5mL simulated sample of the plutonium oxalate precipitation mother liquor, dilute it to 5mL with deionized water, and add 2g / L hydroxyurea solution to destroy the potassium permanganate in the plutonium oxalate precipitation mother liquor;

[0030] (2) Put the test solution obtained in step (1) on the IC-H column, where IC-H is a polystyrene-divinylbenzene strong acid column, and remove Na in the solution + 、K + , Mn 2+ Other cations;

[0031] (3) Put the solution collected in step (2) into a container and heat it at a temperature of 45°C. At the same time, the upper surface of the solution is blown with air until it is completely dry, and the air flow rate is 2L / min;

[0032] (4) Wash the beaker several times with deionized water, collect the...

Embodiment 2

[0039] The method and steps used in Example 1 are the same, except that the heating temperature used is 50° C., the air flow rate is 4 L / min, and the reducing agent used is N,N-dimethylhydroxylamine.

Embodiment 3

[0041] The method and steps used in Example 1 are the same, except that the sample solution is diluted 20 times, the heating temperature used is 58° C., the air flow rate is 6 L / min, and the reducing agent used is hydrazine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com