Improved type four-effect rising film evaporator and concentration method

A falling film evaporator and an improved technology are applied in the field of an improved four-effect falling film evaporator, which can solve the problems of being unsuitable for processing solutions that are easy to crystallize and scale easily, difficulty in uniform liquid film, and low heat transfer coefficient, etc. Achieve the effect of shortening evaporation time, increasing concentration concentration, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

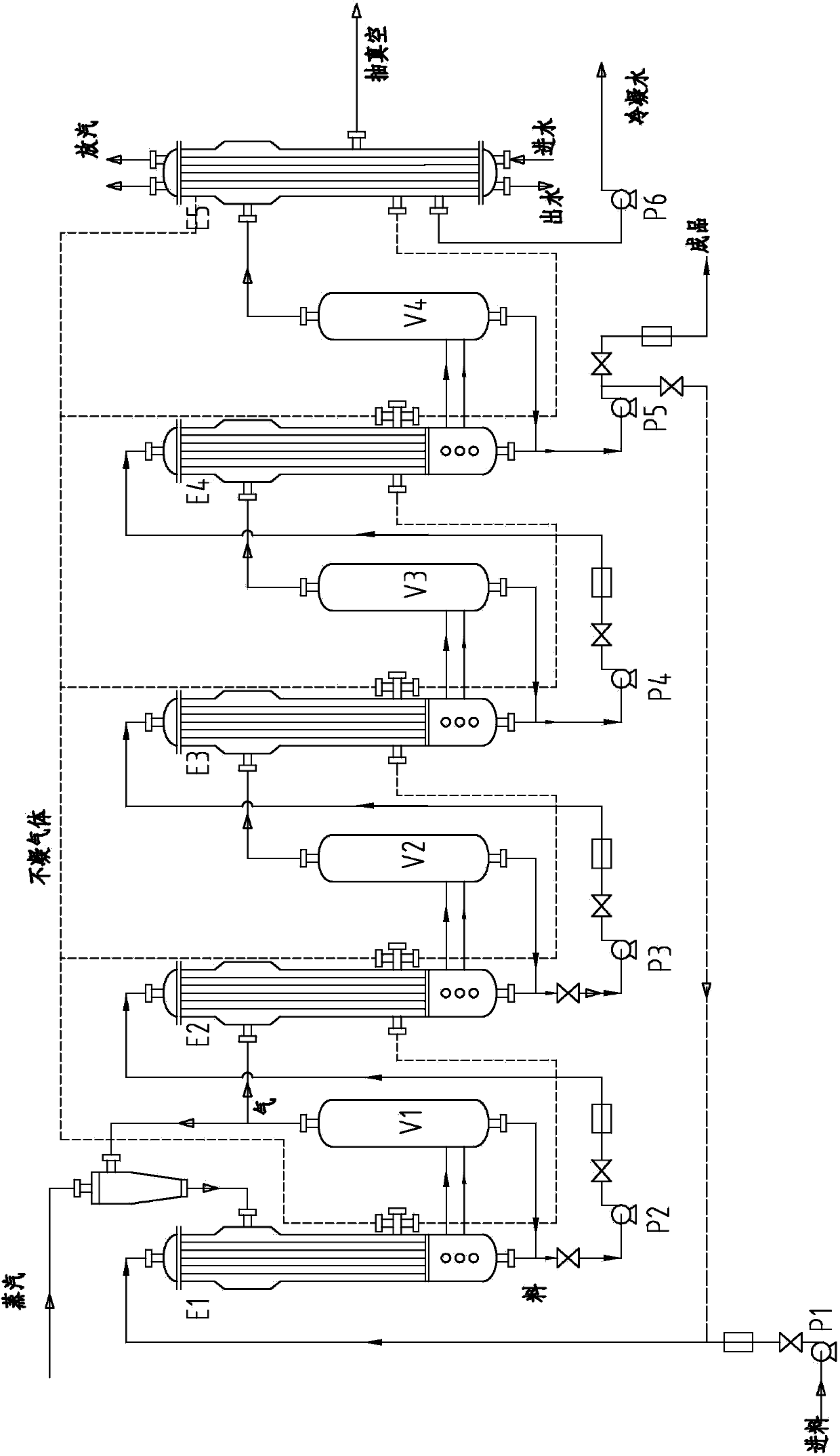

[0023] like figure 1 , image 3 as shown,

[0024] This is a schematic diagram of the four-effect falling film concentration principle before modification. Among them, the four-effect falling film device and process are existing technologies, and the material that has been circulated through the four-effect overall cannot reach the required concentration, and the material needs to be put into another single-effect tank for re-concentration to reach the specified concentration. And the steam loss is relatively large. So modify it.

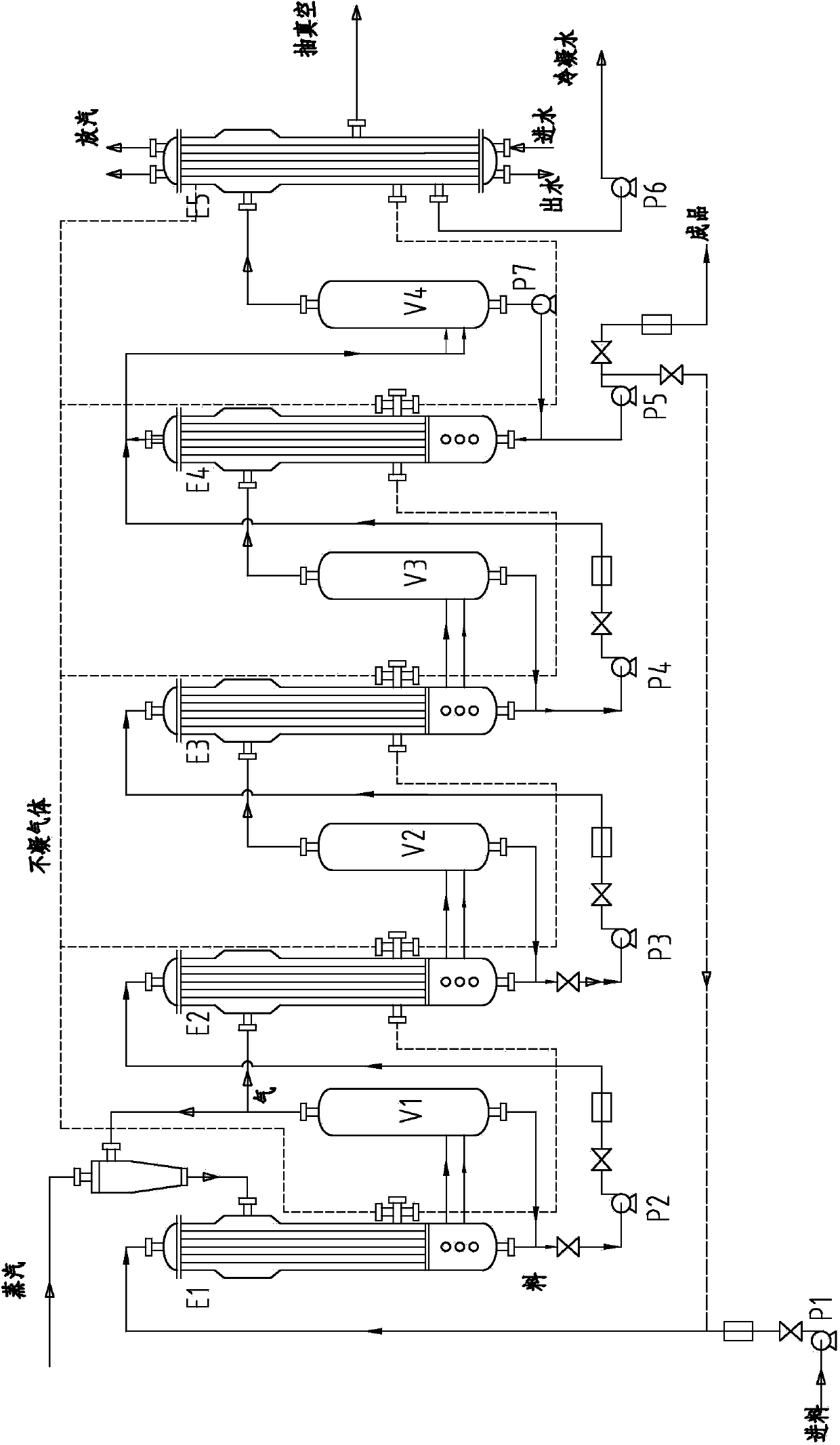

[0025] The modification is done as follows:

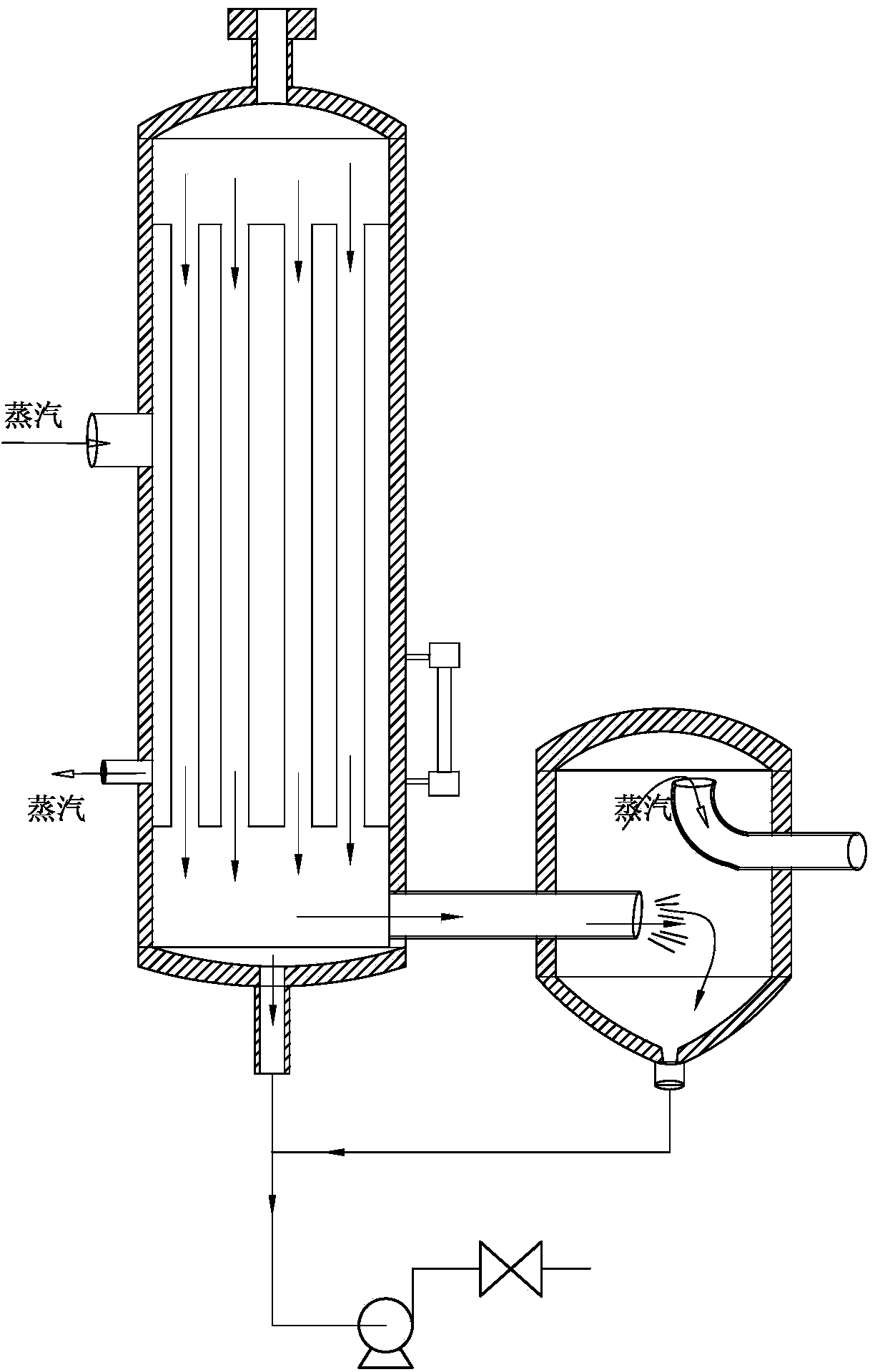

[0026] like figure 2 , Figure 4 and Figure 5 As shown, the material passing through the first three-effect heater and the separator is directly sent to the four-effect separator through the three-effect feeding pump, and no longer flows down from the top of the four-effect heater. Expand the capacity of the four-effect separator to at least 2 times the original volume, that is, increase the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com