Terminal wastewater zero discharging system and method of power plant

A zero-discharge, wastewater technology, applied in separation methods, chemical instruments and methods, gaseous discharge wastewater treatment, etc., can solve the problems of scarcity of power plants, high investment costs, and high water treatment costs per ton

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

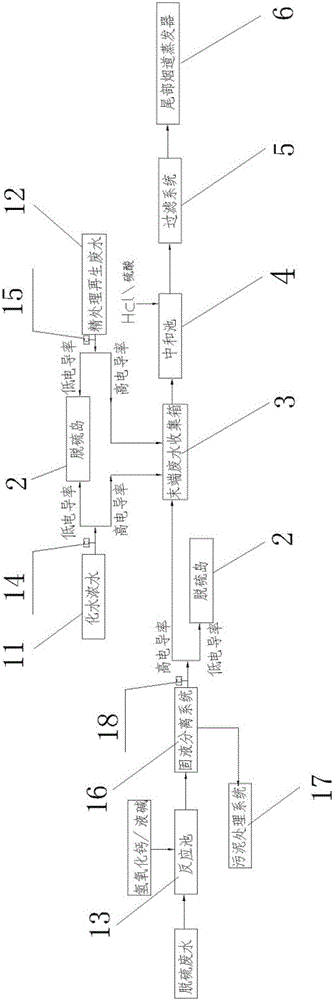

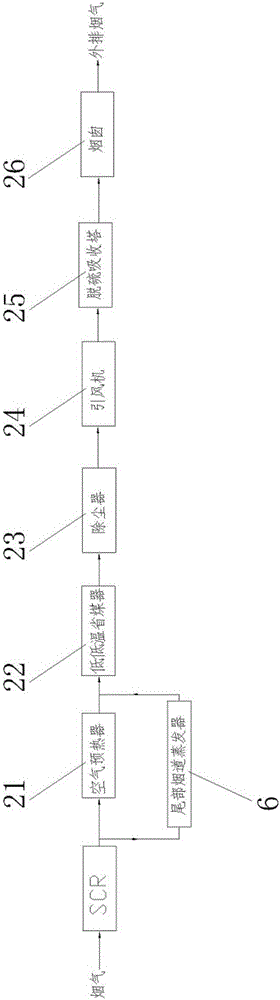

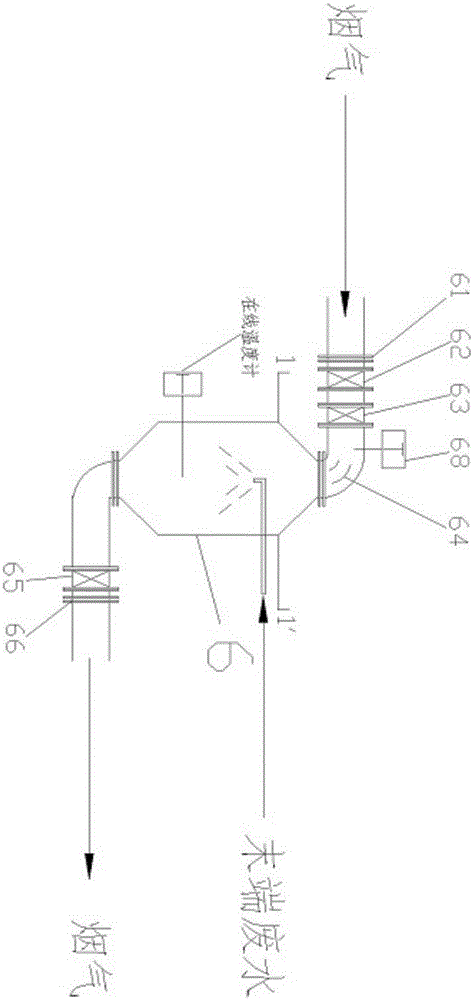

[0072] refer to Figure 1 to Figure 4 As shown, the certain thermal power plant adopted in the present embodiment 1, the various ion concentrations in the desulfurization wastewater of the power plant are representative in the operation of other power plants. That

[0073] (1) The pH range is 5-7, showing weak acidity,

[0074] (2) Water quality of desulfurization wastewater, suspended matter content 350000~50000mg / L

[0075] (3)Ca 2+ The ion content is 500~2000mg / L, Mg 2+ The ion content is 5000~10000mg / L

[0076] (4) Desulfurization wastewater contains a large amount of chloride ions,

[0077] (5) Desulfurization wastewater contains a large amount of metal ions, such as chromium, cadmium, mercury, arsenic, lead, etc.

[0078] (6) Desulfurization wastewater has high salinity,

[0079] The above-mentioned desulfurization wastewater is passed through the chemical water concentrated water collection system, the fine treatment regeneration wastewater collection system and ...

Embodiment 2

[0088] The chemical water concentrated water in the chemical water concentrated water collection tank of the chemical water concentrated water collection system is detected by the first online conductivity measuring instrument. When the conductivity is lower than 15000us / cm, the chemical water concentrated water of the chemical water concentrated water collection system Return to the desulfurization island;

[0089] When the conductivity is higher than 30000us / cm, the concentrated water of the chemical water concentrated water collection system is introduced into the terminal waste water collection tank;

[0090] When the conductivity is 25000us / cm, the first online conductivity measuring instrument 14 sends a third control signal to the diverter valve, the diverter valve is automatically opened, and 20% of the concentrated water of the chemical water returns to the desulfurization island; 80% of the concentrated water of the chemical water enters the Terminal wastewater colle...

Embodiment 3

[0096] The chemical water concentrated water in the chemical water concentrated water collection tank of the chemical water concentrated water collection system is detected by the first online conductivity measuring instrument. When the conductivity is lower than 20000us / cm, the chemical water concentrated water of the chemical water concentrated water collection system Return to the desulfurization island;

[0097] When the conductivity is higher than 30000us / cm, the concentrated water of the chemical water concentrated water collection system is introduced into the terminal waste water collection tank;

[0098] When the conductivity is 25000us / cm, the first online conductivity measuring instrument 14 sends a third control signal to the diverter valve, the diverter valve is automatically opened, and 50% of the concentrated water of the chemical water returns to the desulfurization island; 50% of the concentrated water of the chemical water enters the Terminal wastewater colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com