Desulphurization waste water processing system

A desulfurization wastewater and treatment system technology, applied in the direction of gaseous effluent wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of complex system, high investment and operation costs, and achieve simple process and low maintenance Small size and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

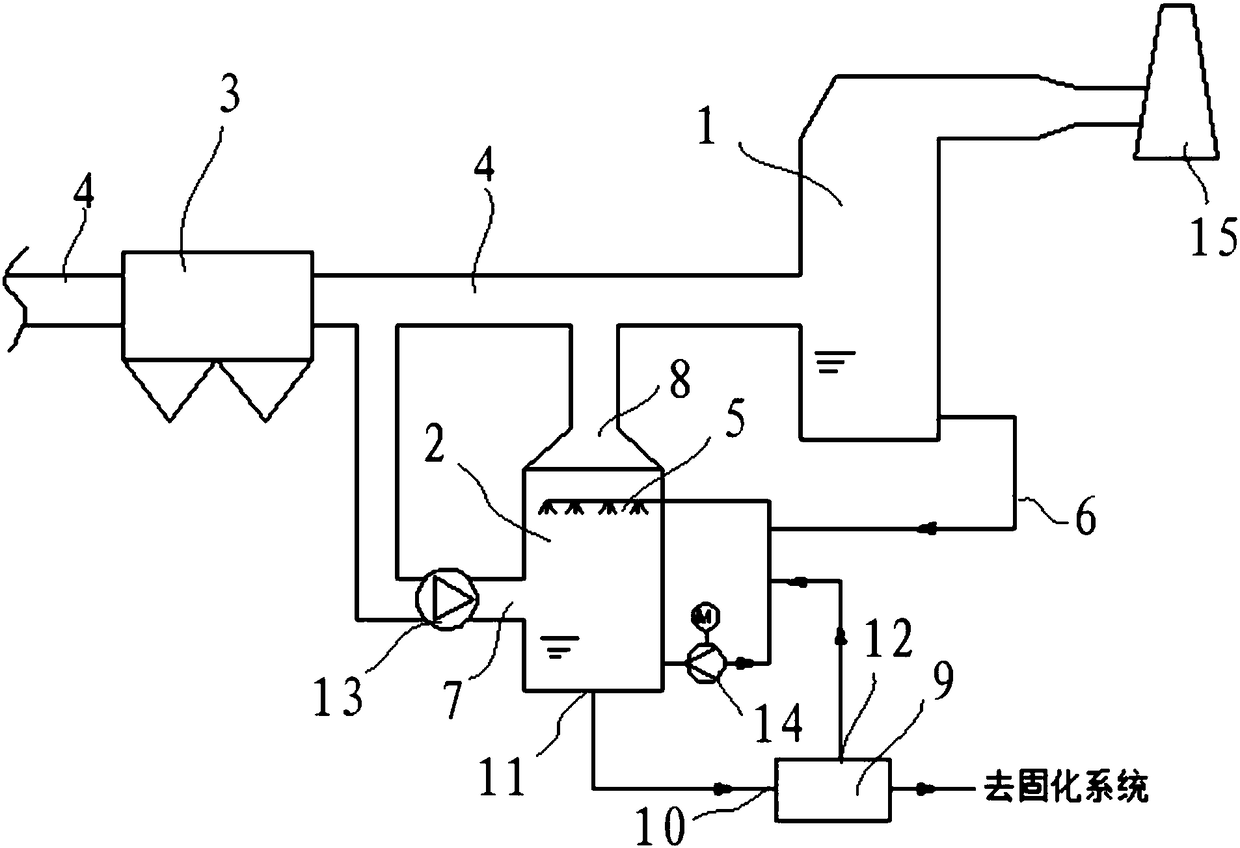

[0022] An embodiment of the desulfurization wastewater treatment system of the present invention, the desulfurization wastewater treatment system described in this embodiment includes a coal-fired boiler (not shown in the figure), an electrostatic precipitator 3, a desulfurization device 1 and a concentration tower 2; The coal-fired boiler, the electrostatic precipitator 3 and the desulfurization device 1 are connected successively through the flue gas pipeline 4, and the nozzle 5 is arranged in the concentration tower 2, and the nozzle 5 is connected with the desulfurization device 1 through the desulfurization waste water pipeline 6; the concentration tower 2 is provided with a flue gas inlet 7 and a flue gas outlet 8, the flue gas inlet 7 is connected with the flue gas outlet 8 on the electrostatic precipitator 3, and the flue gas outlet 8 is connected with the flue gas pipe 4 on the desulfurization device Pass. The desulfurization wastewater treatment system also includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com