Apparatus for concentrating ammonium sulfate slurry by using flue gas enthalpy

A technology of ammonium sulfate slurry and flue gas, which is applied in the direction of ammonium sulfate, evaporator accessories, evaporation, etc., can solve the problems of poor quality of ammonium sulfate products, restrictions on ammonia desulfurization process, high operating costs, etc., and achieve diameter reduction, The effect of saving investment and reducing the volume of flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

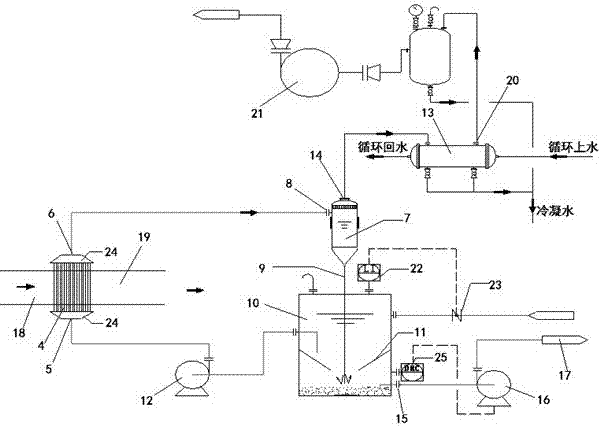

[0025] Such as figure 1 As shown, a device for concentrating ammonium sulfate slurry using flue gas heat enthalpy includes a tubular heat exchanger 4 connected to the flue of the desulfurization tower, and the bottom of the tube side of the tubular heat exchanger 4 is provided with ammonium sulfate slurry Liquid inlet 5, the tube side top of described tubular heat exchanger 4 is provided with ammonium sulfate steam outlet 6, and described ammonium sulfate steam outlet 6 links to each other with the ammonium sulfate steam inlet 8 on the buffer tank 7, and described buffer tank 7 The bottom is connected with the reflux pipe 9 that is used to export the ammonium sulfate-containing slurry, and the reflux pipe 9 stretches into the crystallization circulation tank 10 bottom, and the crystallization circulation tank 10 inwall is connected with a funnel-shaped crystallization tank ring plate 11, and the reflux The pipe 9 passes through the ring plate 11 of the crystallization tank, an...

Embodiment 2

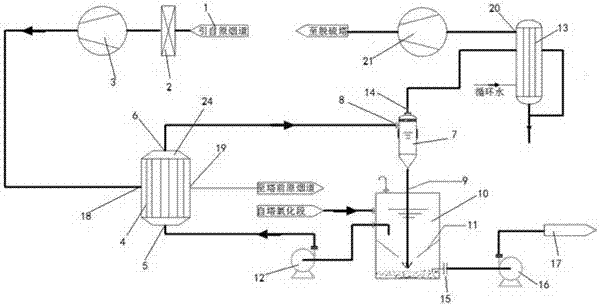

[0039] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is only that the tubular heat exchanger 4 is not built into the flue of the desulfurization tower, but a branch flue 1 is drawn from the flue of the desulfurization tower, and the branch flue An induced draft fan A3 is arranged behind the channel 1, and the tube heat exchanger 4 is connected behind the induced draft fan A3, which is an external type. The branch flue 1 is provided with a flapper valve 2 for adjusting the flow of flue gas, and the flapper valve 2 is located in front of the induced draft fan A3. The branch flue 1 in front of the tubular heat exchanger 4 is made of carbon steel; the branch flue 1 behind the tubular heat exchanger 4 is made of carbon steel when the smoke temperature is calculated to be higher than the dew point. Steel material, when the smoke temperature is calculated to be lower than the dew point, the carbon steel lining flake material is used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com