Disposable filter means for smoking

a filter and smoking technology, applied in the field of smoking and smoking devices, can solve the problems of lessening the enjoyment derived from smoking, frequent burnt areas immediately in communication with the exit portal of the burning chamber, and laborious cleaning of the pipes and cigarette holders, so as to facilitate heat exchange, reduce the temperature of smoke passing, and increase the amount of waste cooled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

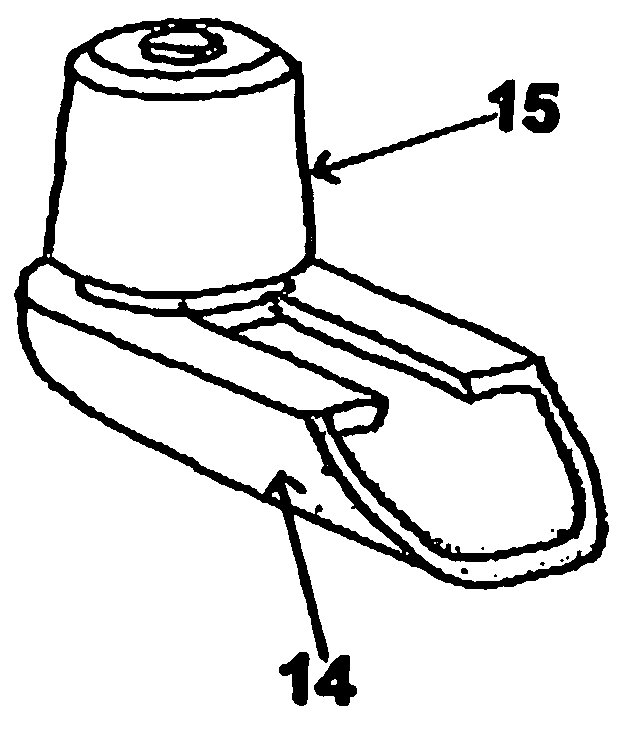

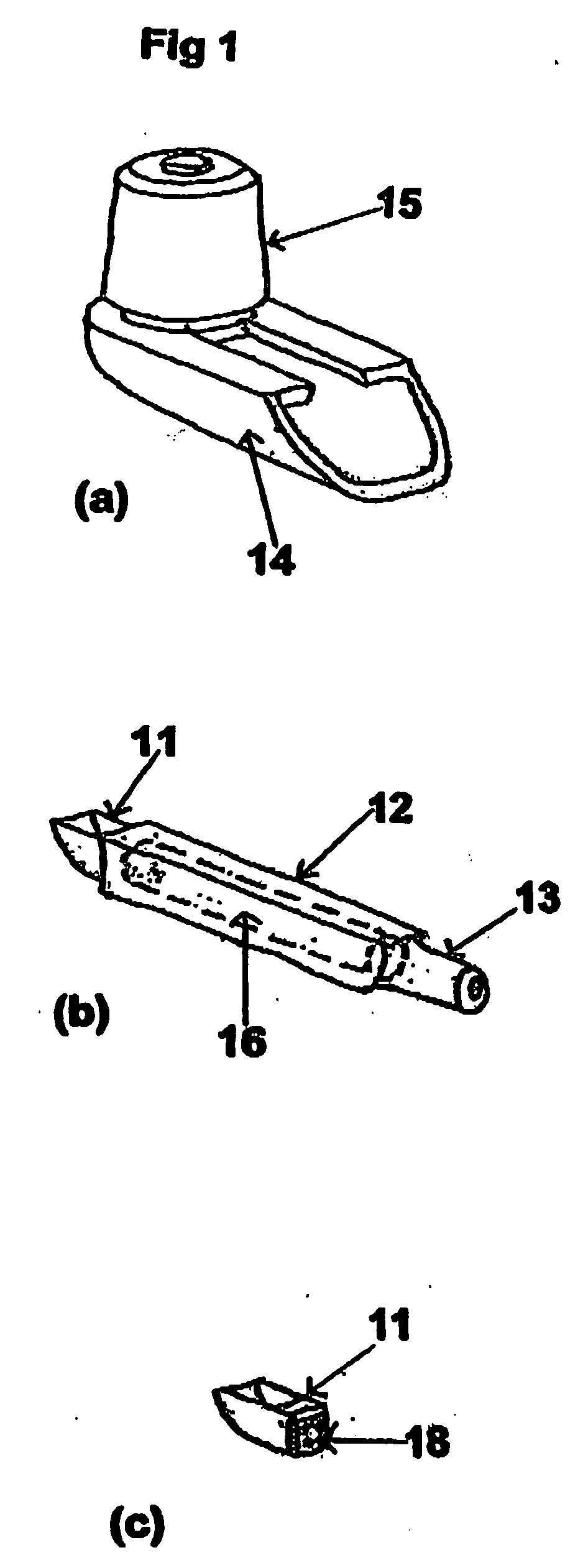

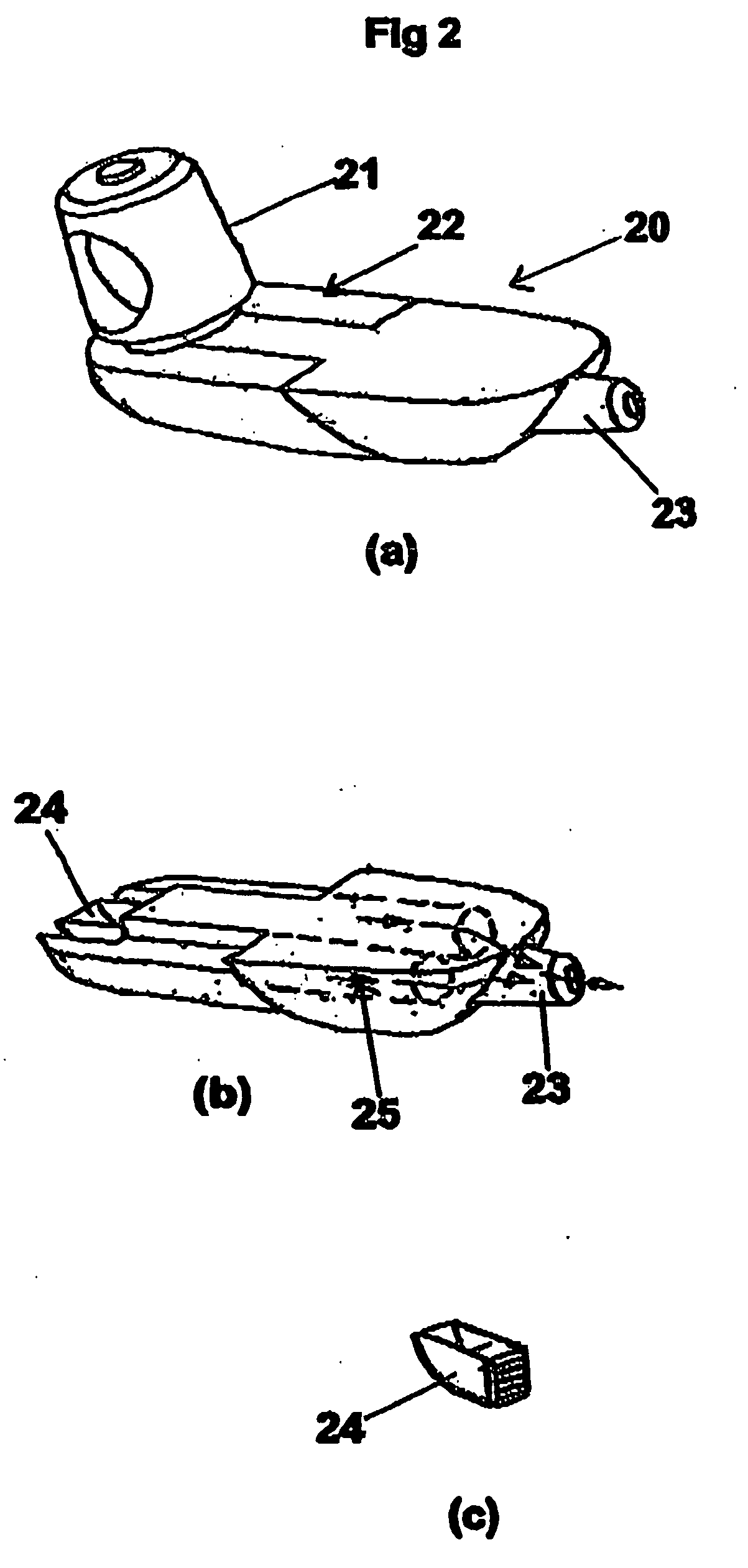

[0059] With reference to FIG. 1, there is shown an unassembled smoking device comprising a receiving member in the form of a shank trap 11, a filter housing 12 with a mouth piece 13, stem 14 and bowl 15. The shank trap 11 is attachable to the filter housing 12 at the opposing end to the mouth piece 13. The filter housing 12 has an acetate paper filter 16 (shown in phantom) locatable within the housing 12. The filter housing 12 with the shank trap 11, when assembled forms a filter assembly locatable within stem 14. The bowl 15 is locatable on the stem 14. When assembled, the burning chamber of the bowl 15 is in communication with the shank trap 11 and the filter housing 12. Smoke from the burning chamber passes into the shank trap 11 as the smoker draws on the mouthpiece 13, the smoke then passes through the paper acetate filter 16 within the filter housing 12 and is inhaled by the smoker. The shank trap 11 is shaped to collect moisture, tar and other end products while allowing smok...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com