Desulfurization process and device with zero wastewater discharge

A desulfurization process and desulfurization device technology are applied in the field of desulfurization process with zero discharge wastewater, which can solve the problems of increasing costs, increasing the external drainage volume of the desulfurization system, affecting the quality and moisture content of gypsum of desulfurization products, and achieving the goal of reducing the moisture content and improving the quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

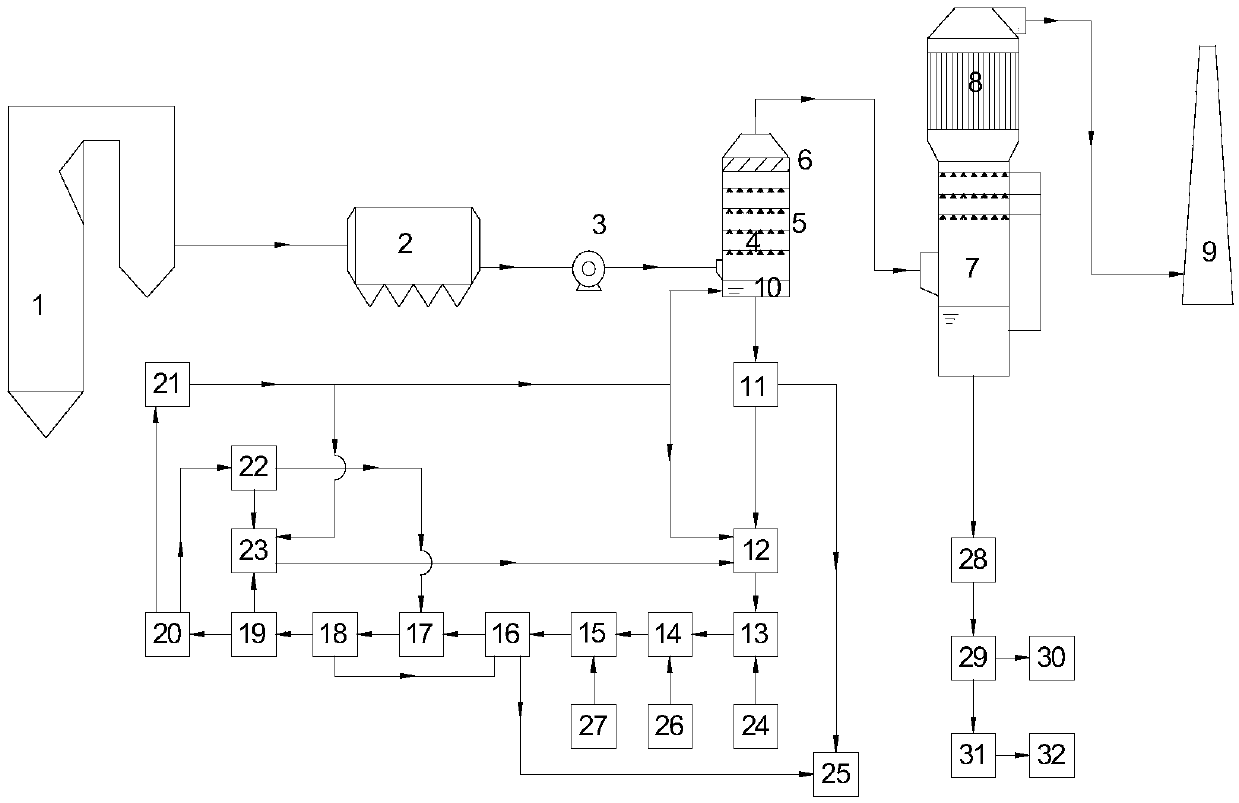

Image

Examples

Embodiment 1

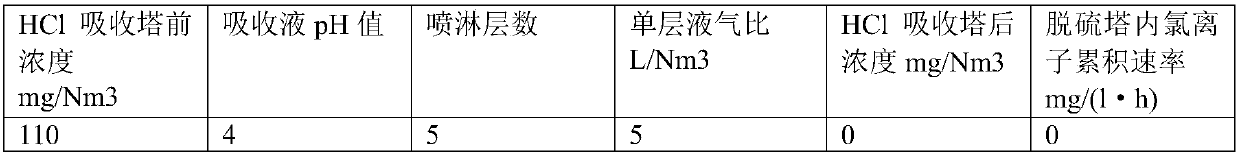

[0079] The initial flue gas volume of a 35t / h coal-fired chain furnace is 59854Nm3 / h, and the HCl content in the flue gas is 110mg / Nm 3 , the flue gas enters the existing desulfurization process after going through the hydrogen chloride absorption process, and the desulfurization tower design column slurry is 48m 3 , the control concentration of chlorine ion in the wastewater discharged from the desulfurization tower is 20000mg / l. The pH value of the circulating absorption solution in the hydrogen chloride absorption process is 4, and the pH regulator is 15% sodium hydroxide solution, as shown in Table 1:

[0080] Table 1

[0081]

[0082] The salt content of the hydrogen chloride absorption liquid is 15% and the waste water discharged from the desulfurization tower undergoes pretreatment, ultrafiltration, ion exchange, electrodialysis and other processes to prepare the waste water into acid and alkali.

Embodiment 2

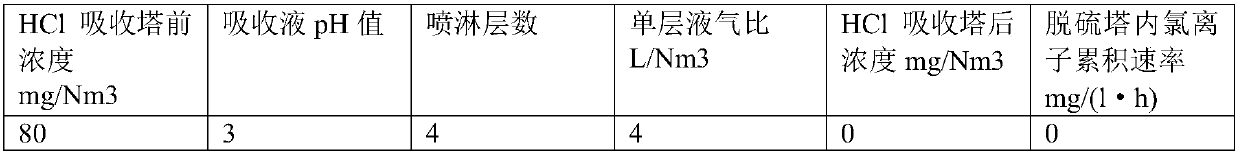

[0084] The initial flue gas volume of a 35t / h coal-fired chain furnace is 59560Nm3 / h, and the HCl content in the flue gas is 80mg / Nm 3 , the flue gas enters the existing desulfurization process after going through the hydrogen chloride absorption process, and the desulfurization tower design column slurry is 48m 3 , the control concentration of chlorine ion in the wastewater discharged from the desulfurization tower is 20000mg / l. In the hydrogen chloride absorption process, the pH value of the circulating absorption liquid is controlled to be 3, and the pH regulator is 5% sodium hydroxide solution, as shown in Table 2:

[0085] Table 2

[0086]

[0087] The salt content of the hydrogen chloride absorption liquid is 5% and the wastewater discharged from the desulfurization tower undergoes pretreatment, ultrafiltration, ion exchange, electrodialysis and other processes to prepare the discharged wastewater into acid and alkali.

Embodiment 3

[0089] The initial flue gas volume of a 35t / h coal-fired chain furnace is 60125Nm3 / h, and the HCl content in the flue gas is 80mg / Nm 3 , the flue gas enters the existing desulfurization process after going through the hydrogen chloride absorption process, and the desulfurization tower design column slurry is 48m 3 , the control concentration of chlorine ions in the wastewater discharged from the desulfurization tower is 10000mg / l. The pH value of the circulating absorption solution in the hydrogen chloride absorption process is 3.5, and the pH regulator is 10% sodium hydroxide solution, as shown in Table 3:

[0090] table 3

[0091]

[0092] The salt content of the hydrogen chloride absorption liquid is 10% and the waste water discharged from the desulfurization tower undergoes pretreatment, ultrafiltration, ion exchange, electrodialysis and other processes to prepare the discharged waste water into acid and alkali.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com