Storage battery waste acid resource treatment method

A treatment method and resource-based technology, applied in the field of waste acid treatment, can solve problems such as high energy consumption, sales difficulties, and overcapacity, and achieve the effects of low consumption of circulating cooling water, low operating costs, and reduced energy consumption costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

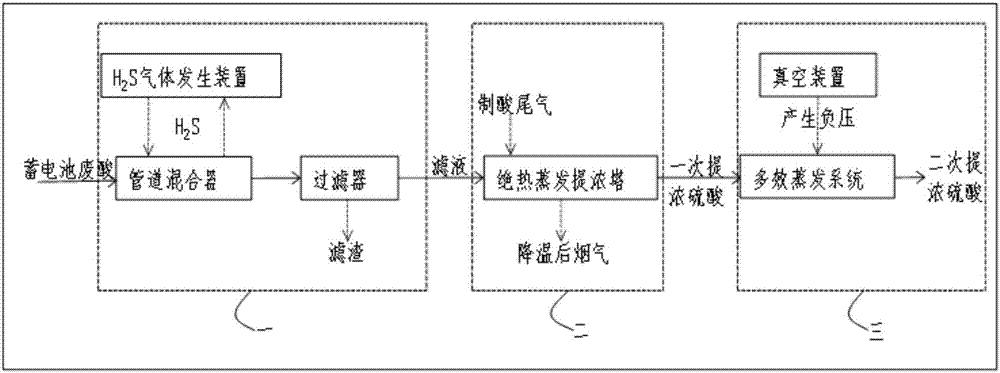

Method used

Image

Examples

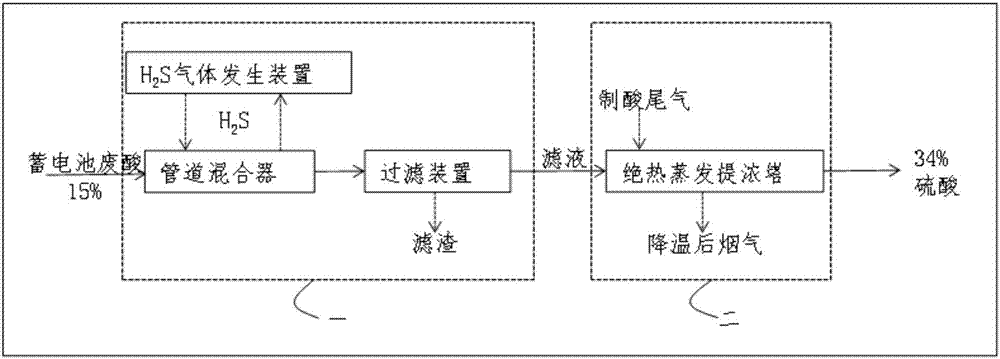

Embodiment 1

[0042] In this embodiment, the amount of waste battery acid to be treated is 2t / h, and the acid concentration is 15%, which contains a small amount of heavy metals and solid impurities; 3 / h, the concentration of sulfuric acid in the acid solution after treatment is required to reach 34%, and the impurity content meets the acid standard for battery acid; the equipment used in the adiabatic evaporation concentration tower is a power wave device, and the material is made of high-temperature resistant glass fiber reinforced plastic.

[0043] Theoretical calculation of acid concentration after adiabatic evaporation in this embodiment:

[0044] 10000Nm 3 Moisture taken away by adiabatic evaporation of flue gas: 0.23m 3 (Moisture taken away when the flue gas is reduced to 45°C)

[0045] Adiabatic evaporation of water takes away water: 0.23*5=1.15m 3 / h

[0046] The required processing capacity of dilute acid: 2t / h (acid concentration 15%)

[0047] Acid concentration after adiab...

Embodiment 2

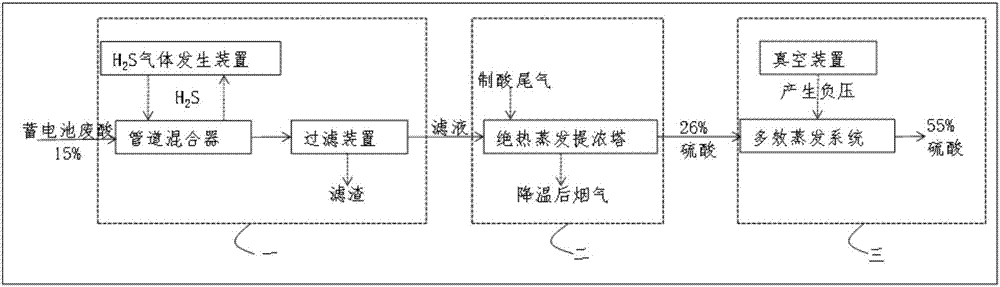

[0057] The amount of waste battery acid to be treated in this embodiment is 2t / h, the acid concentration is 15%, and contains a small amount of heavy metals and solid impurities; the gas volume of the high-temperature acid-making tail gas (75°C) used in this embodiment is 50000Nm 3 / h, the acid concentration after treatment is required to reach 55%, and the impurity content meets the acid standard for battery acid; the equipment used in the adiabatic evaporation concentration tower is a venturi tube, and the material is high-temperature-resistant glass fiber reinforced plastic.

[0058] Theoretical calculation of acid concentration after adiabatic evaporation in this embodiment:

[0059] 10000Nm 3 Moisture taken away by adiabatic evaporation of flue gas: 0.18m 3 (Moisture taken away when the flue gas is reduced to 55°C)

[0060] Adiabatic evaporation of water takes away water: 0.18*5=0.9m 3 / h

[0061] Dilute acid requires design capacity: 2t / h (calculated based on 15% aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com