Ferroalloy electric furnace flue gas purifying and dust recovering novel technology and device thereof

A technology of dust recovery and flue gas purification, which is applied in the direction of climate change adaptation, climate sustainability, chemical instruments and methods, etc., to achieve the effect of high strength, simple system and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

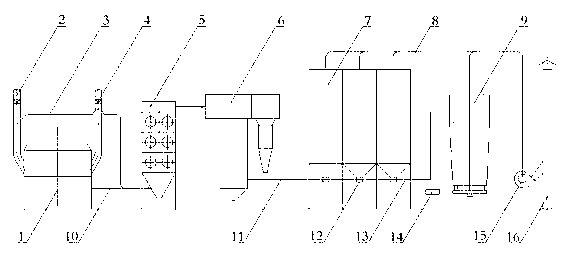

[0016] The present invention is described in detail below in conjunction with accompanying drawing:

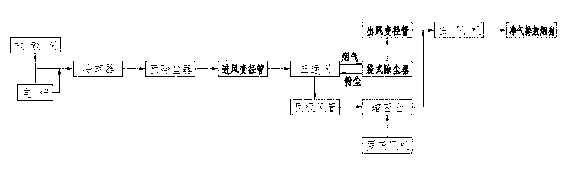

[0017] The steps of the new technology for dust recovery from the flue gas purification of the ferroalloy electric furnace are as follows: after the flue gas discharged from the electric furnace is subjected to pre-dust removal, purification and dust removal, the dust is stored and densified, and the flue gas is discharged into the atmosphere through the exhaust chimney, wherein the purification and dust removal adopts Bottom air intake, upper exhaust air, negative pressure, inner filter type, room-by-chamber anti-suction dust-cleaning large bag filter, the purified flue gas is discharged from the top of the large bag filter, and is discharged through the outlet variable diameter pipe and the main fan. The chimney is discharged, and at the same time, through the negative pressure anti-suction device in front of the main fan, the anti-suction dust removal and pneumatic ash trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com