Wet desulfurization synergized fine particle and SO3 acid mist removing method and device

A technology for fine particulate matter, wet desulfurization, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

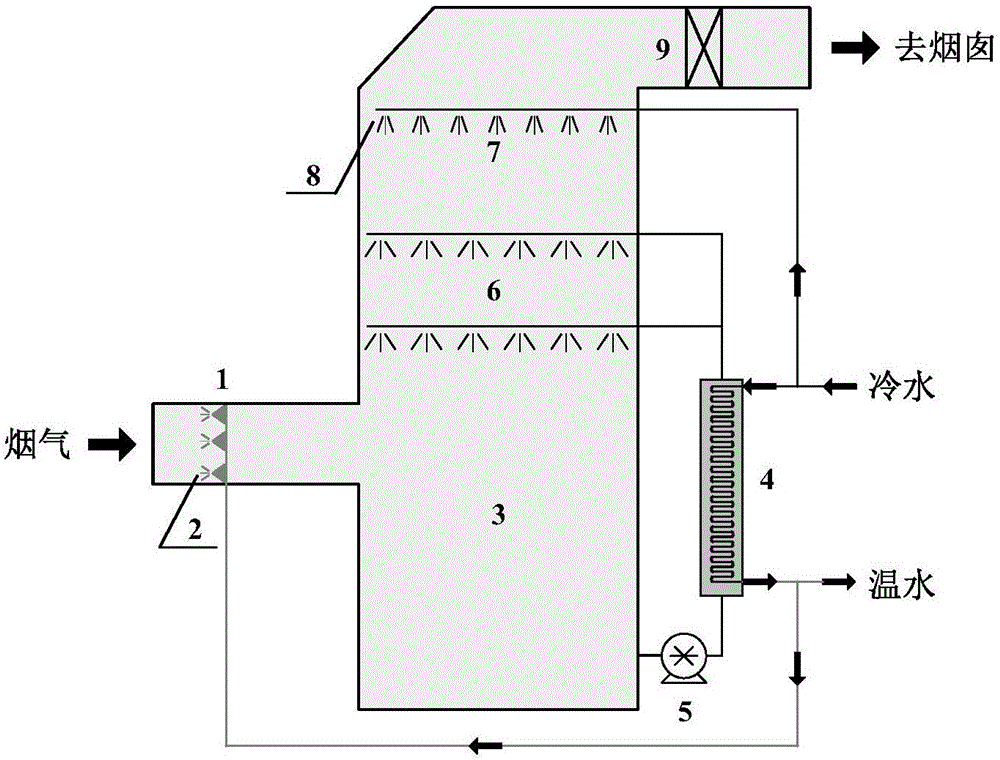

[0036] Such as figure 1 As shown, the wet desulfurization of the present invention synergistically removes fine particles and SO 3 The acid mist device mainly consists of a flue gas cooling and humidifying device 1, a desulfurization tower 3, a desulfurization scrubber heat exchanger 4, and a cold water spray layer 7 on the top of the desulfurization tower. The flue gas cooling and humidifying device 1 is installed at the inlet flue of the desulfurization tower 3, and a dual-fluid atomizing nozzle 2 is installed inside; the desulfurization scrubbing liquid heat exchanger 4 is installed on the desulfurization scrubbing liquid inlet pipe, and the heat exchanger cooling water adopts upward inlet Bottom out arrangement; the cold water spray layer 7 on the top of the desulfurization tower is set between the high-efficiency defogger 9 on the upper part of the desulfurization tower 2 and the desulfurization washing liquid spray layer 6. The distance between the cold water spray layer 7...

Embodiment 2

[0040] The flue gas is produced by a fully automatic coal-fired boiler, and the flue gas volume is 350Nm 3 / h, supplemented by aerosol generator, SO 3 The generator adds an appropriate amount of coal-fired fly ash and SO to the flue gas 3 , So that the dust concentration in coal-fired flue gas is 44mg / m 3 , Where the concentration of fine particles is 16mg / m 3 , SO 3 The concentration is 39mg / m 3 . The system consists of a flue gas cooling and humidification device, a desulfurization tower, a desulfurization scrubbing liquid heat exchanger, a desulfurization scrubbing liquid spray layer, a cold water spray layer on the top of the desulfurization tower, and a high-efficiency demister; the desulfurization tower uses limestone / gypsum flue gas Desulfurization. The desulfurization scrubber heat exchanger is a fluoroplastic heat exchanger, and the heat exchange tube diameter is 6mm fluoroplastic tube. The wet desulfurization tower adopts a spray tower with a tower diameter of 219mm a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com