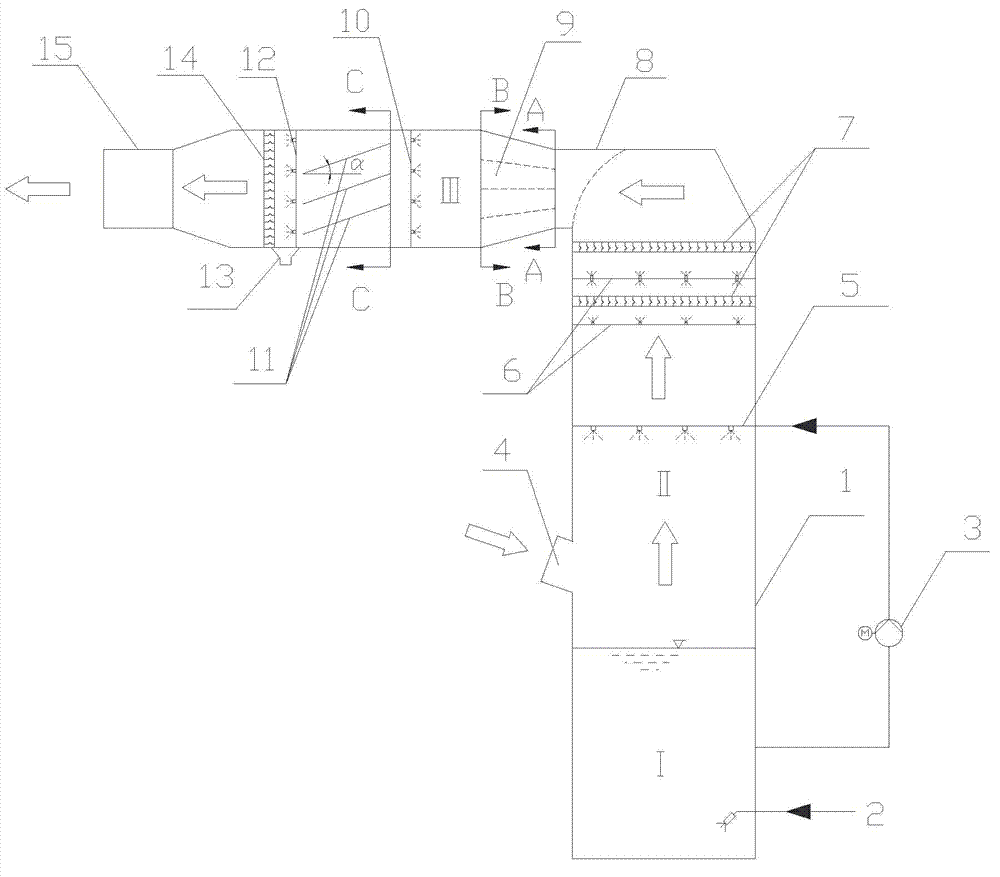

Method and device for synergistically removing fine particles via wet-process flue gas desulfurization

A wet flue gas desulfurization and fine particle technology, which is applied to combined devices, separation methods, chemical instruments and methods, etc., can solve the problem of increased equipment costs, removal of fine particles, uneven mixing of steam and flue gas containing fine particles, etc. problem, to achieve the effect of good effect, equipment investment and construction cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

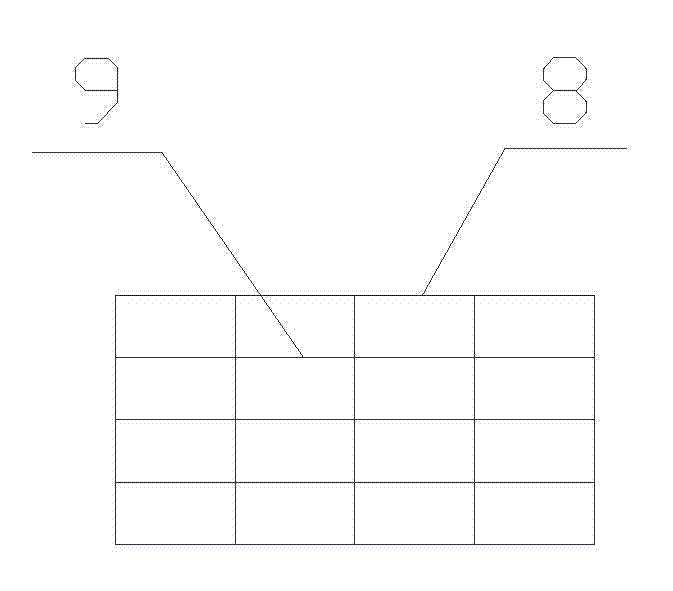

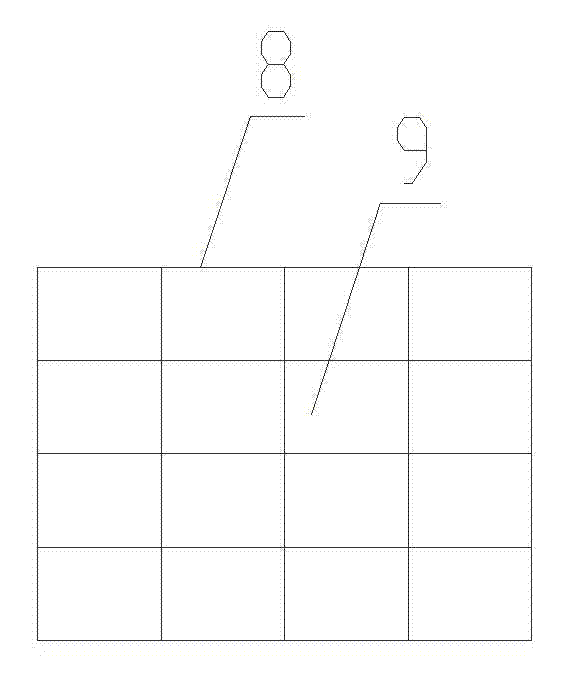

[0029] Taking the flue gas of a coal-fired boiler as the processing object, the flue gas volume is 1.0×10 5 N m 3 / h, the temperature of the original flue gas is 118°C, and the mass concentration of the flue dust at the inlet of the desulfurization tower is 70mg / Nm 3 , SO 2 Concentration 1747 mg / Nm 3 , with limestone slurry as the absorbent, the section of the clean flue gas uniform distributor 9 is divided into 16 pieces of equal area, and 3 pieces of flue partitions 11 are set at an angle of 30° to the flow direction of the flue gas, and the steam phase changes The amount of steam injected into the area is 0.04kg / Nm 3 ;After the flue gas is treated, the temperature of the flue gas at the chimney outlet is 49°C, and the mass concentration of the flue gas is 28mg / Nm 3 , to meet the emission concentration of smoke and dust stipulated in the "Emission Standard of Air Pollution for Thermal Power Plants" (GB13233-2011) less than 30mg / Nm 3 emission standard, SO 2 Concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com