Method and device for removing PM2.5 (particulate matter) in WFGD (wet flue gas desulfurization) process

A wet desulfurization and removal technology, applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., can solve the problem of no obvious effect on the removal of coal-fired ultrafine particles, increase the power consumption of induced draft fans, and increase the resistance of the flue, etc. problem, to achieve the effect of increasing the length and resistance of the flue, saving equipment investment and construction costs, and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

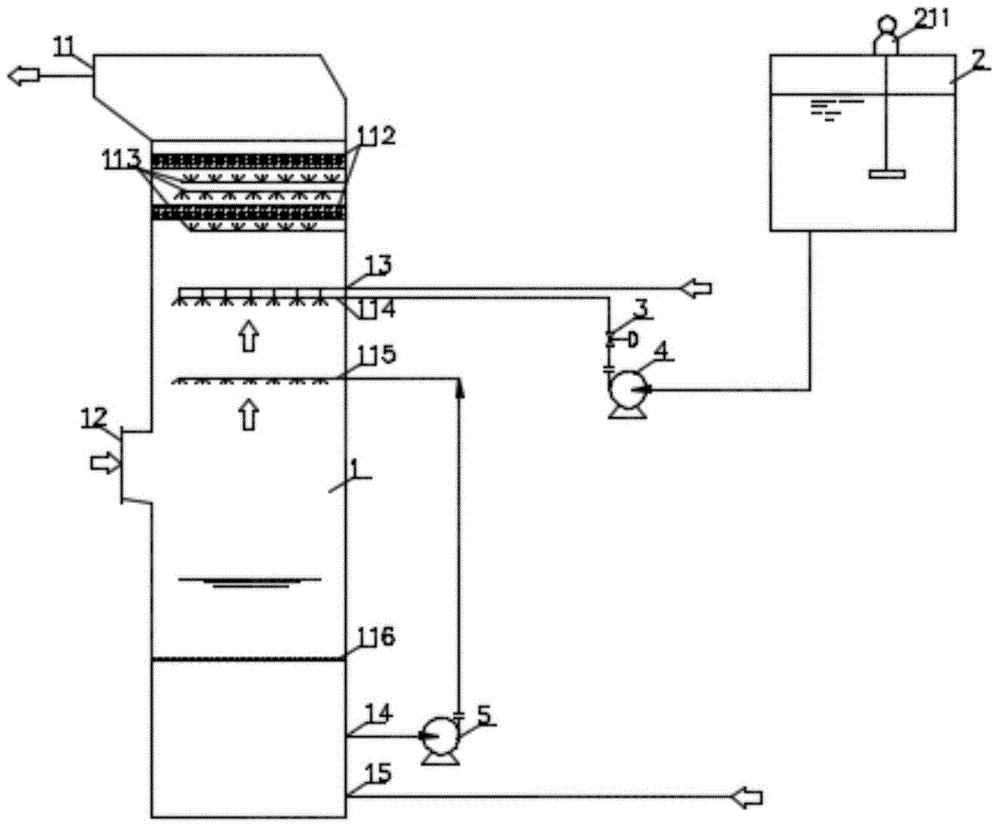

[0026] Below in conjunction with accompanying drawing, device of the present invention is further explained:

[0027] PM in wet desulfurization process 2.5 The removal device includes a desulfurization absorption tower 7, the top of the desulfurization absorption tower is provided with a net flue gas outlet 11, and the upper section is provided with at least one layer of mist eliminator 112, and each layer of mist eliminator 112 is equipped with a mist eliminator Cleaning device 113; the middle section of the desulfurization absorption tower is provided with a raw flue gas inlet 12, and a desulfurization liquid spray layer 115 is arranged above the original flue gas inlet 12, and a flocculant atomization spray layer is arranged above the desulfurization liquid spray layer 115 114, the flocculant atomized spray layer 114 has a flocculant inlet and a factory air inlet 13; a floc filter 116 is provided below the liquid level in the lower section of the desulfurization absorption ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com