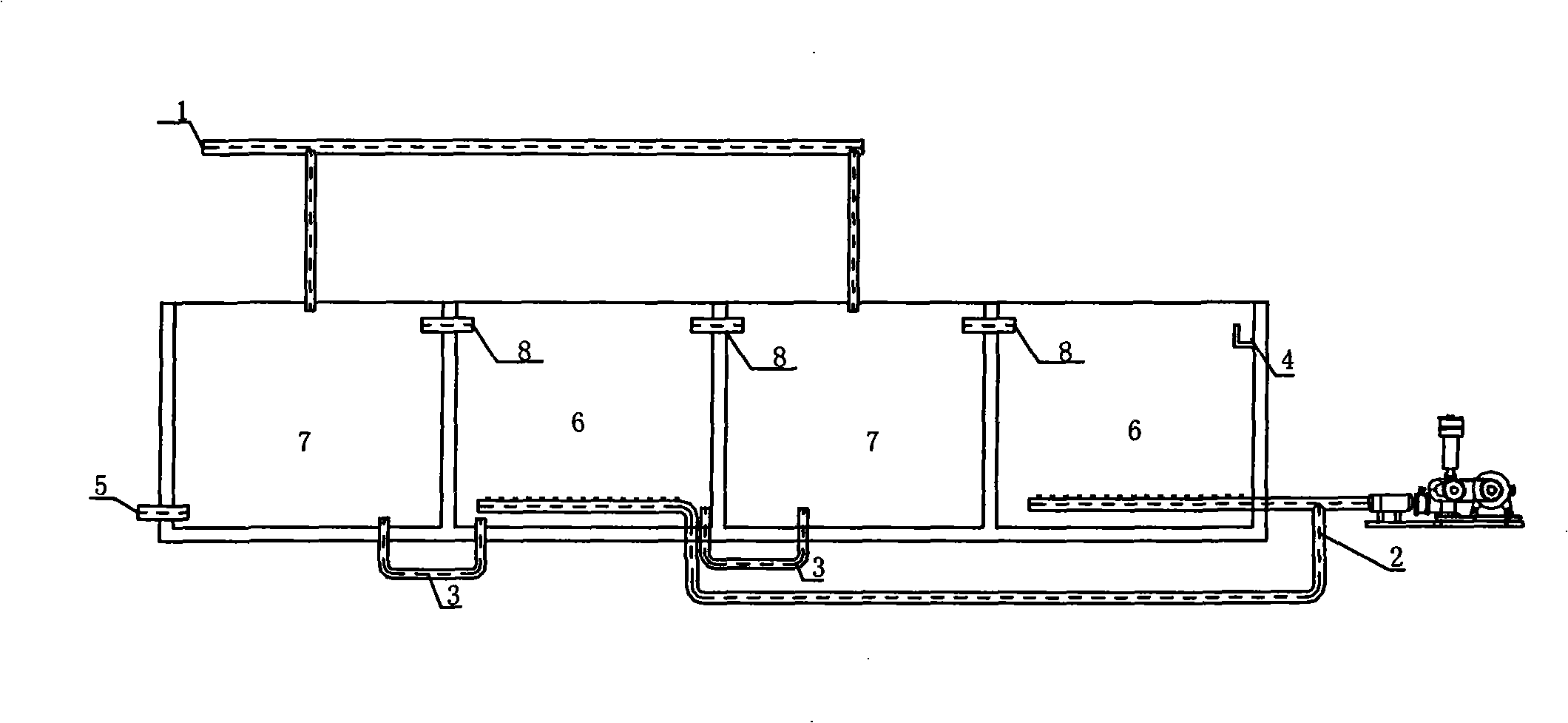

Two-stage water supply bio denitrification system and process thereof

A technology of biological denitrification and water inflow system, which is applied in the field of two-stage water inflow biological denitrification system, can solve the problems of high operating cost and large investment, and achieve the effects of low operating cost, convenient operation and management, and low capital investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A protein wastewater, the water volume is 4000m 3 / d, the pool body adopts a rectangular steel concrete structure, BRN influent water COD is 820mg / L, BOD is 300mg / L, ammonia nitrogen is 240mg / L, effluent COD is about 80mg / L, removal rate is about 90.2%, BOD is 20mg / L or so, the removal rate is about 93.3%, ammonia nitrogen <10mg / L, the removal rate is about 95.8%, which is better than the first-level discharge standard in the "Comprehensive Wastewater Discharge Standard of the People's Republic of China" (GB8978-1996), and the operating cost Low, the water output is relatively stable.

Embodiment 2

[0044] Transformation of a certain protein wastewater, water volume is 3120m 3 / d, the original aerobic project used the SBR process, and the effluent water quality was poor, and both N and P exceeded the emission concentration stipulated by the state. After the transformation, the aerobic process used the BRN process. The COD of the BRN influent water quality was 1000mg / L, and the BOD was 400mg / L, ammonia nitrogen 250mg / L, effluent COD is about 80mg / L, removal rate is about 92%, BOD is about 20mg / L, removal rate is about 95%, ammonia nitrogen <10mg / L, removal rate is about 95.8% , the total P is less than 1.0mg / L, which is better than the first-level discharge standard in the "Integrated Wastewater Discharge Standard of the People's Republic of China" (GB8978-1996). After the transformation, the operation effect has been very good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com