Desulfurization device and desulfurization method for promoting removal of PM2.5 in clean flue gas after wet desulphurization

A desulfurization device, wet desulfurization technology, applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of high steam consumption, high energy consumption, large resistance, etc., to improve the washing and trapping effect, trap Improve collection efficiency and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

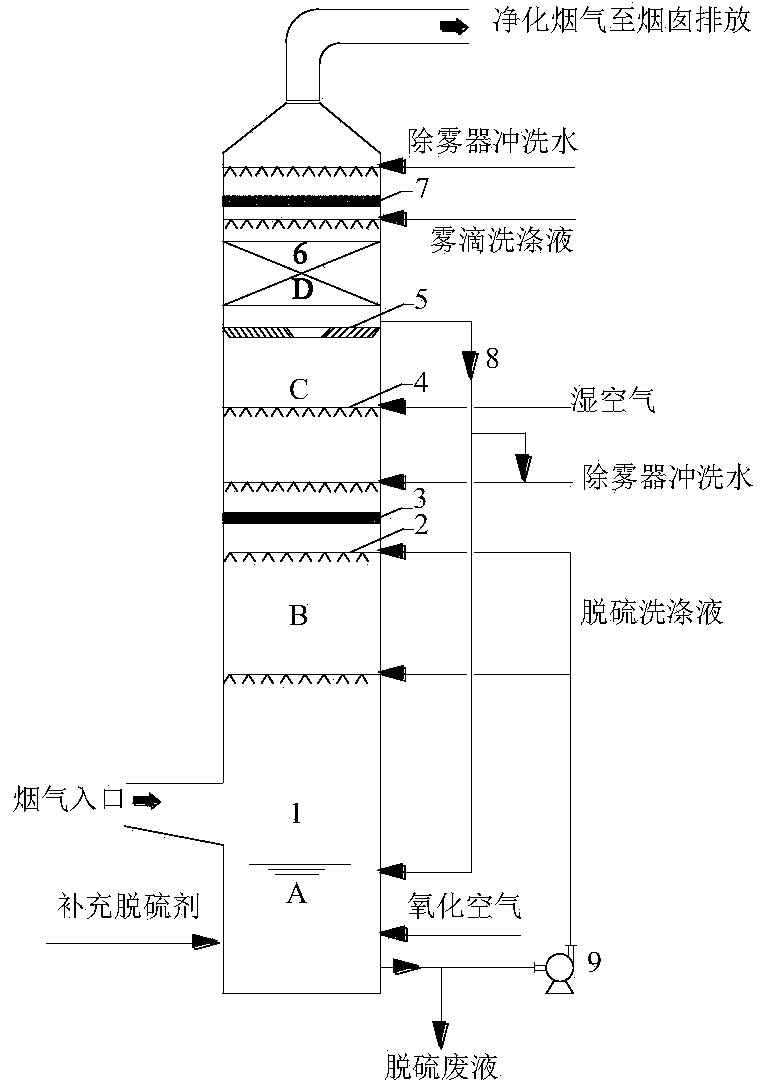

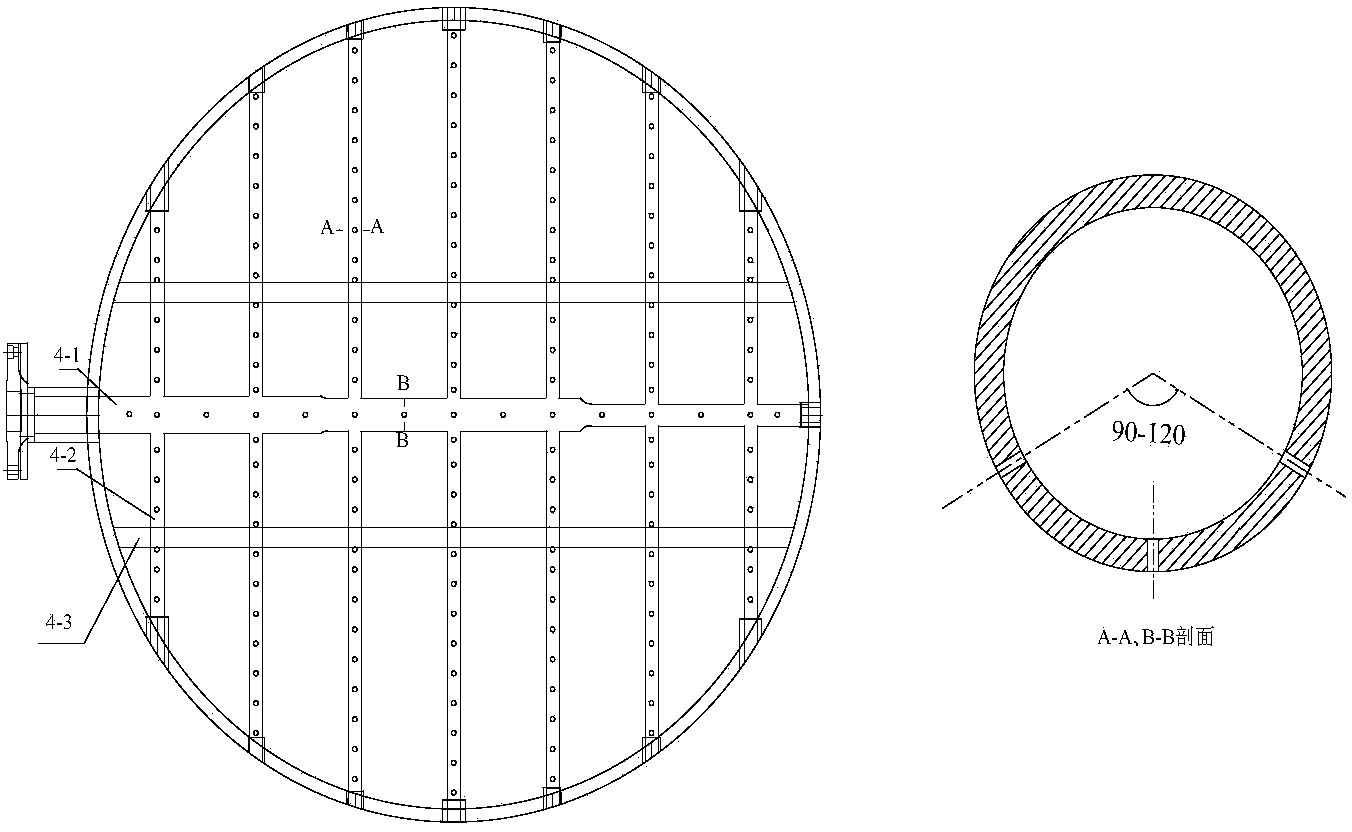

[0035] A desulfurization device, applied to the PM in the promoted wet desulfurization net flue gas 2.5 In the removal method, the desulfurization tower 1 of the desulfurization device is an absorption tower with multi-stage functional sections, the bottom of the tower is the desulfurization liquid oxidation zone A, the middle part is the desulfurization washing zone B, and the top is PM 2.5 The water vapor phase change region C where condensation and growth occurs and the droplet trapping device D that traps the dusty mist after condensation grows. In the desulfurization liquid oxidation zone A, there are oxidation air inlet, supplementary desulfurizer inlet and desulfurization washing liquid outlet. The flue gas inlet is provided at the lower part of the desulfurization washing area B, and the desulfurization washing liquid inlet is provided at the top, which can adopt empty tower spray, tray or packing structure. A wet air distributor 4 is provided in the middle of the wat...

Embodiment 2

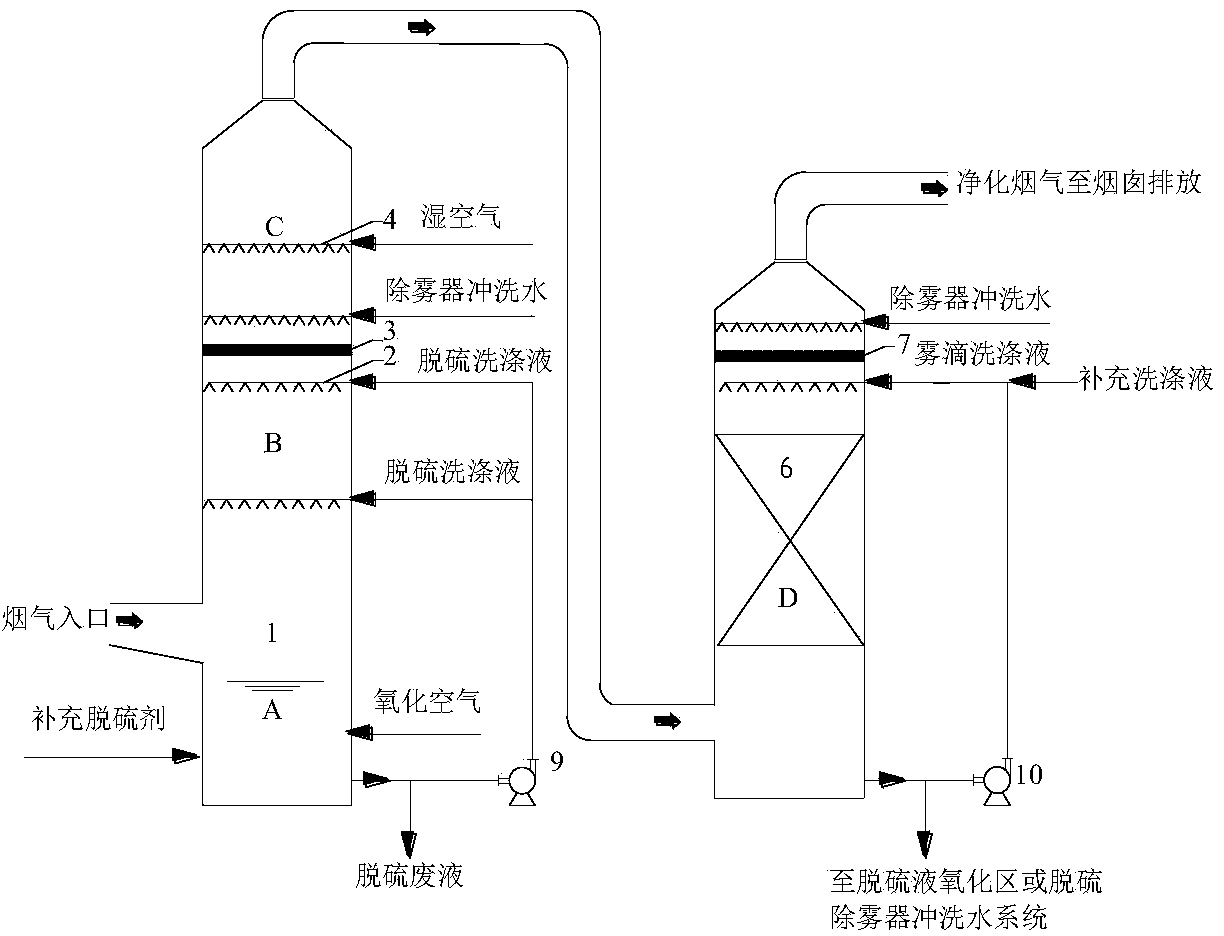

[0038] Such as figure 2 As shown, the difference from Example 1 is that the droplet trapping device D and the flue gas desulfurization washing device are split, the flue gas desulfurization washing device is a desulfurization tower 1, and the desulfurization tower 1 only includes the desulfurization liquid oxidation zone A, desulfurization Washing area B and water vapor phase change area C; the mist trapping device can be a structure such as a spray scrubber, a packed scrubber, a Venturi scrubber, etc., and the washing liquid and the demister flushing water after trapping the dust mist Part of it is recycled by the mist washing liquid circulation pump 10, and part of it is returned to the desulfurization liquid oxidation zone A or used as flushing water for the desulfurization eliminator 3. All the other are with embodiment 1.

Embodiment 3

[0040] The flue gas is produced by a fully automatic coal-fired boiler with a flue gas volume of 300Nm 3 / h, the desulfurization tower adopts a spray tower with a tower diameter of 200mm and a tower height of 4500mm, three-stage spraying, and a liquid-gas ratio of 18L / Nm 3 , The wet desulfurization technology is the limestone-gypsum method. The upper part of the desulfurization tower is equipped with a water vapor phase change area and a droplet collection device, and a baffle demister is installed between the water vapor phase change area and the desulfurization washing area; a washing liquid collector is installed between the water vapor phase change area and the droplet collection device. The liquid collector communicates with the desulfurization liquid oxidation zone through an overflow pipe, and a humid air distributor is installed in the middle of the water vapor phase change zone; two pieces of metal orifice corrugated structured packing are installed in the droplet tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com