High-efficient demisting device in wet desulfurization tower

A technology of wet desulfurization and defogging devices, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. Improve efficiency, speed up the process of flue gas demisting, and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

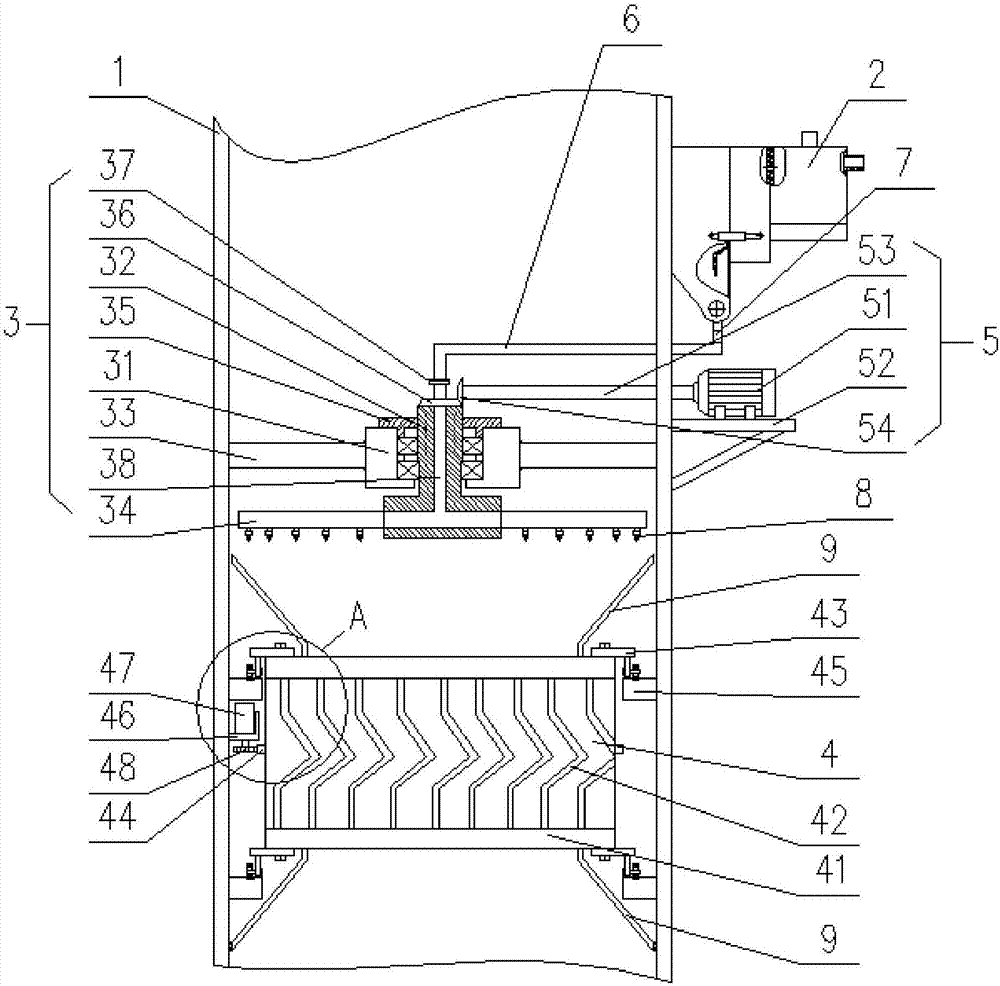

[0030] Specific implementation mode one: combine Figure 1-Figure 7 Describe this embodiment, a high-efficiency wet desulfurization tower internal defogging device in this embodiment includes a desulfurization tower body 1, an alkali-water mixing device 2, a spray device 3, a folding plate demister 4, and a spray drive device 5 , the alkaline water mixing device 2 is installed on the outer wall of the desulfurization tower body 1, the alkaline water mixing device 2 provides water source for the spraying device 3, and the spraying device 3 and the folding plate demister 4 are arranged on the desulfurization tower from top to bottom. In the tower body 1, the folding plate demister 4 is rotatably installed in the tower body 1 of the desulfurization tower;

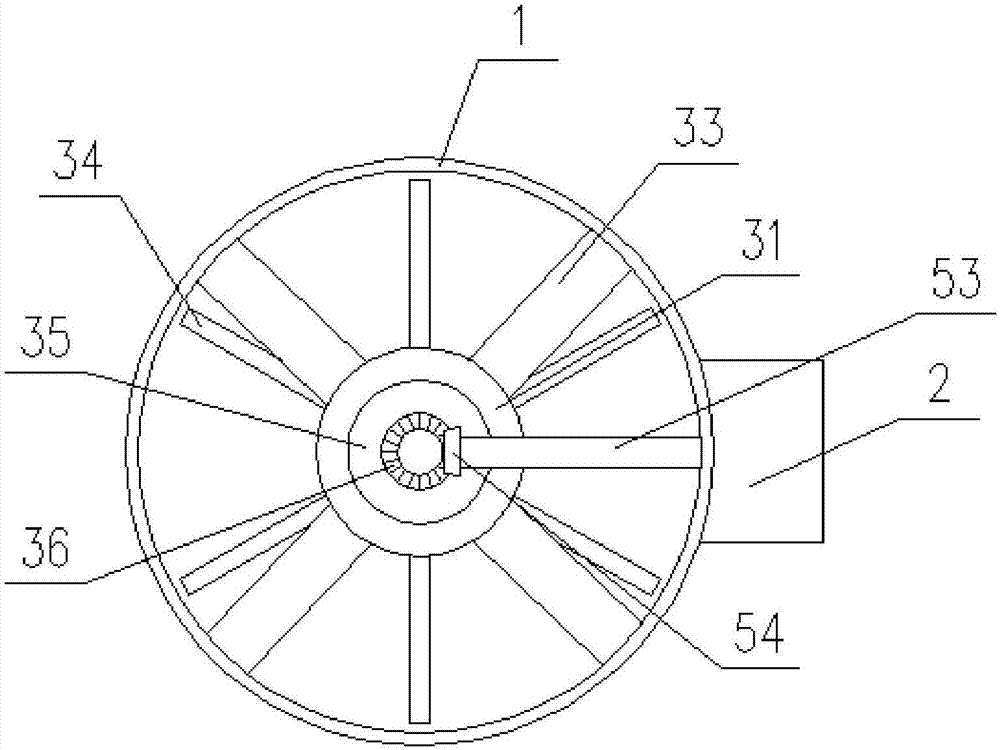

[0031] The spray device 3 includes a support seat 31, a spray pipe mounting seat 32, a support frame 33, a spray pipe 34, a support seat mounting cover 35, a first bevel gear 36 and a water pipe universal joint 37. The support...

specific Embodiment approach 2

[0033] Specific implementation mode two: combination Image 6 To illustrate this embodiment, a plurality of rotating nozzles 8 are regularly arranged on the spray pipe 34 of a high-efficiency wet desulfurization tower internal defogging device of this embodiment. In this way, under the action of the rotating nozzle 8, the solution sprayed by the spray pipe is in the form of diffused mist.

specific Embodiment approach 3

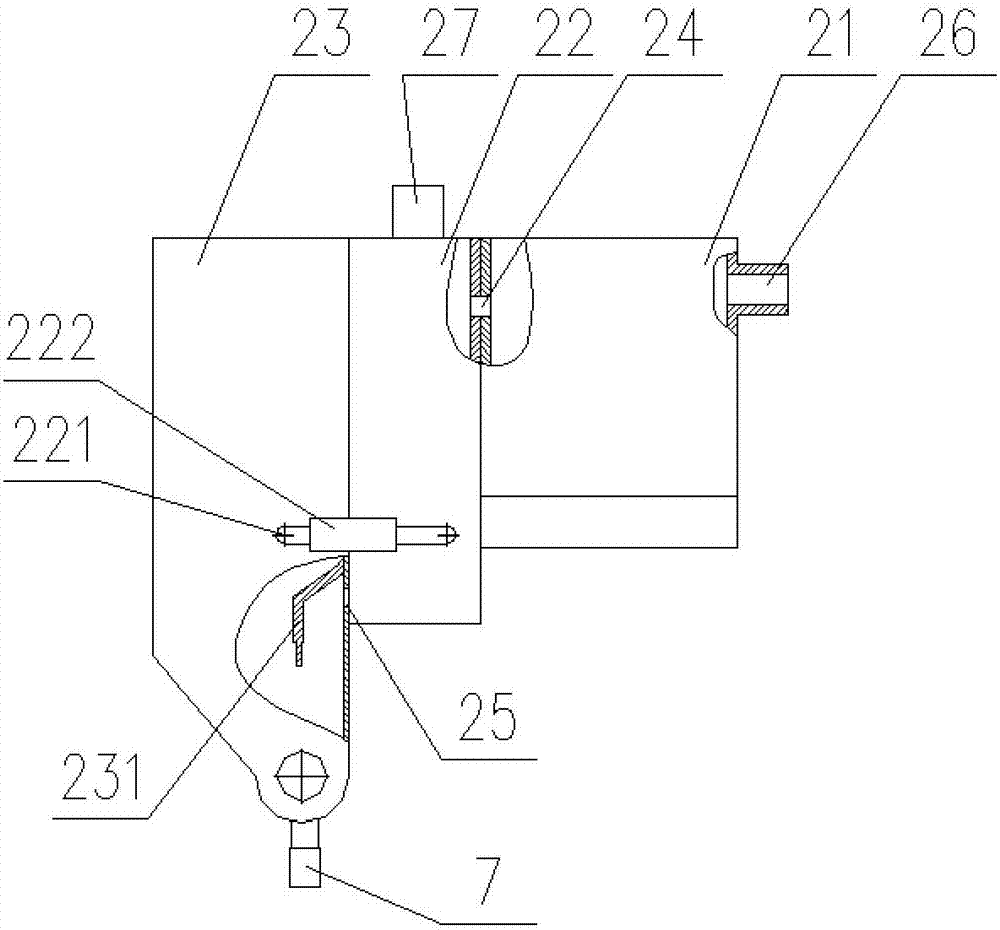

[0034] Specific implementation mode three: combination image 3 , Figure 4Describe this embodiment, the alkaline water mixing device 2 described in a high-efficiency wet desulfurization tower internal defogging device of this embodiment includes a water storage tank 21, a feed tank 22 and a mixing tank 23, and the mixing tank 23 is a bucket Shape feed box, feed box 22 is connected with water storage tank 21 and mixing box 23 respectively, and the installation joint of water storage tank 21 and feeding box 22 has several water injection holes 24, the installation of feeding box 22 and mixing box 23 There are several through-holes 25 at the joint, a water inlet 26 is provided on the side wall of the water storage tank 21, a feed inlet 27 is provided at the upper end of the feed box 22, and a stirring shaft 28 is installed at the bottom of the mixing box 23, and the stirring shaft 28 passes through Bearing is installed on the front and back end faces of mixing box 23, and stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com