Vertical power demister

A mist eliminator and power technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as unsatisfactory mist elimination effect, and achieve good mist elimination effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

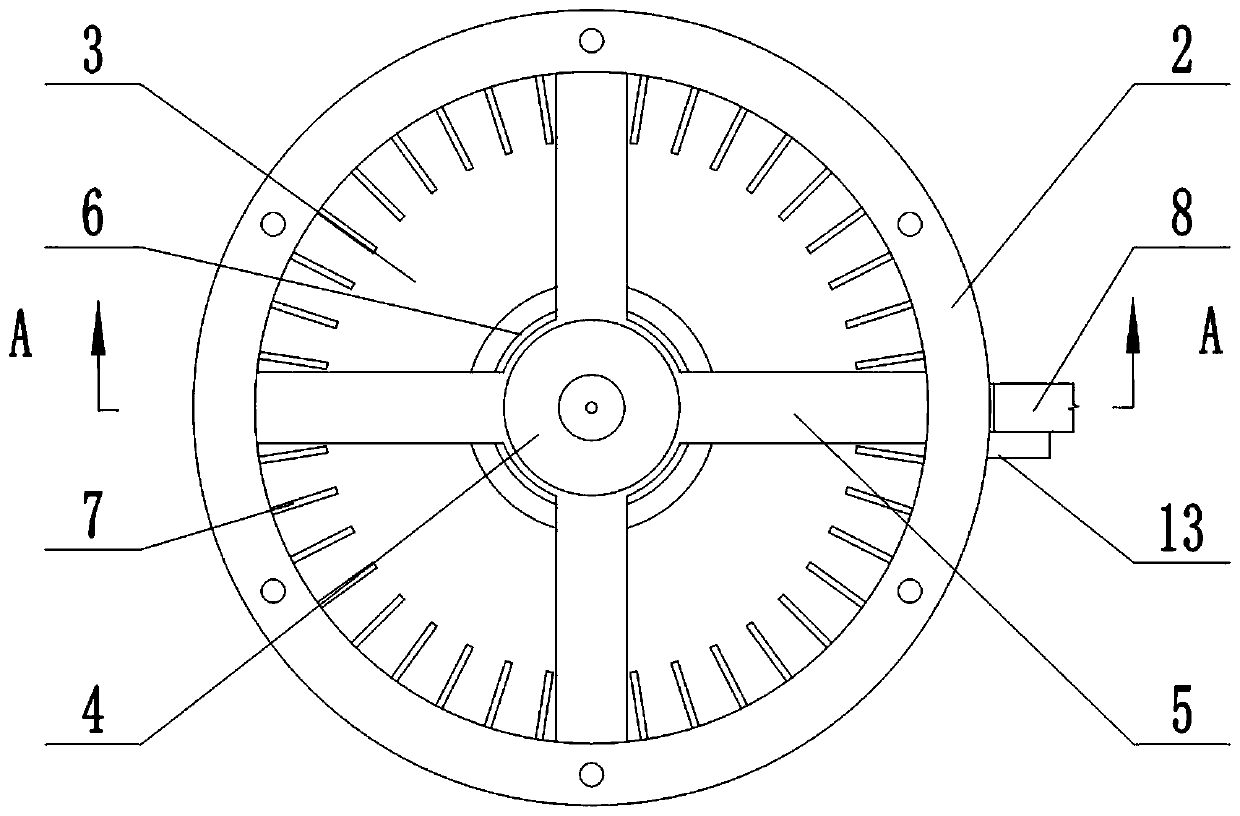

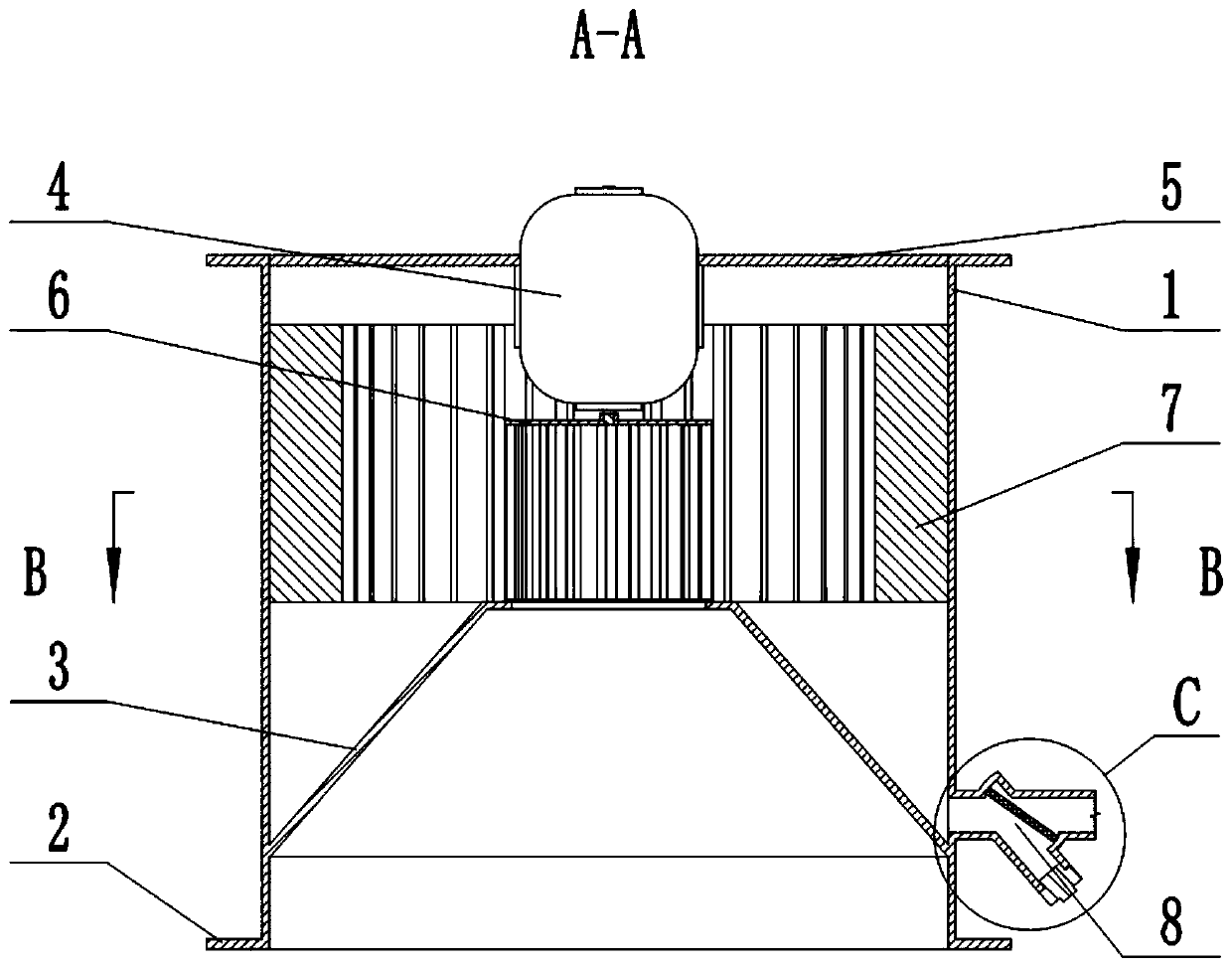

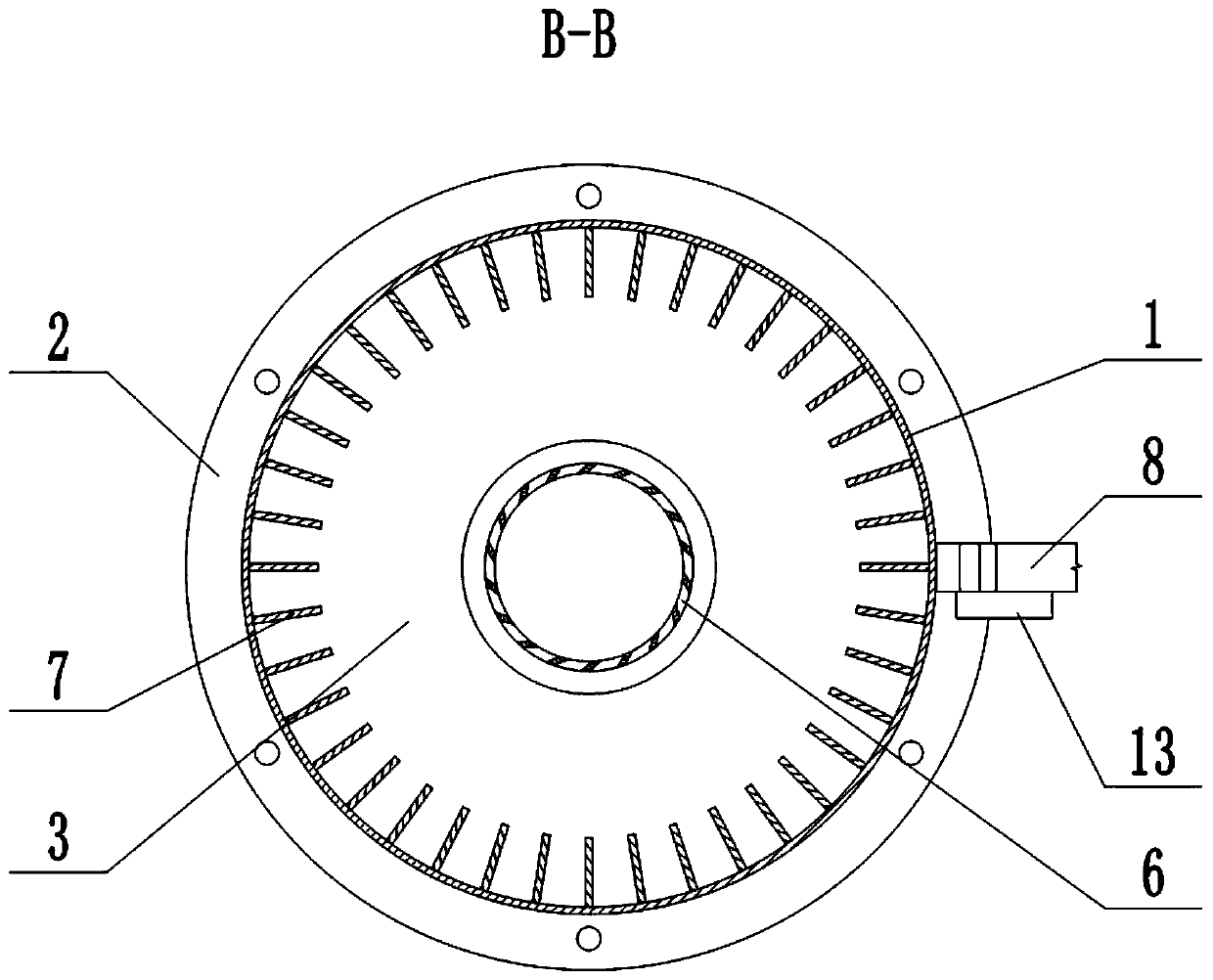

[0028] A vertical power demister, including a cylinder body 1, flanges 2 are fixed on the top and bottom of the cylinder body 1, and a guide plate 3 is provided inside the cylinder body 1, and the guide plate 3 guides the inside of the cylinder body 1 The space is divided into an air outlet chamber and an air inlet chamber from top to bottom in sequence. The diameter of the air inlet end at the bottom of the guide plate 3 is larger than the air outlet end at the top, and the bottom side wall of the guide plate 3 is fixedly connected with the inner wall of the cylinder body 1. There is a main motor 4 inside the cavity, and the main motor 4 is fixedly connected to the top inner wall of the cylinder body 1 through the support ribs 5. The main motor 4 is vertically arranged and the output shaft at the bottom is fixedly connected to the squirrel cage wind wheel 6, and the squirrel cage wind wheel 6 Located above the air outlet end of the guide plate 3, several fins 7 are fixed verti...

Embodiment 2

[0033] A vertical power demister, including a cylinder body 1, flanges 2 are fixed on the top and bottom of the cylinder body 1, and a guide plate 3 is provided inside the cylinder body 1, and the guide plate 3 guides the inside of the cylinder body 1 The space is divided into an air outlet chamber and an air inlet chamber from top to bottom in sequence. The diameter of the air inlet end at the bottom of the guide plate 3 is larger than the air outlet end at the top, and the bottom side wall of the guide plate 3 is fixedly connected with the inner wall of the cylinder body 1. There is a main motor 4 inside the cavity, and the main motor 4 is fixedly connected to the top inner wall of the cylinder body 1 through the support ribs 5. The main motor 4 is vertically arranged and the output shaft at the bottom is fixedly connected to the squirrel cage wind wheel 6, and the squirrel cage wind wheel 6 Located above the air outlet end of the guide plate 3, several fins 7 are fixed verti...

Embodiment 3

[0038] A vertical power demister, including a cylinder body 1, flanges 2 are fixed on the top and bottom of the cylinder body 1, and a guide plate 3 is provided inside the cylinder body 1, and the guide plate 3 guides the inside of the cylinder body 1 The space is divided into an air outlet chamber and an air inlet chamber from top to bottom in sequence. The diameter of the air inlet end at the bottom of the guide plate 3 is larger than the air outlet end at the top, and the bottom side wall of the guide plate 3 is fixedly connected with the inner wall of the cylinder body 1. There is a main motor 4 inside the cavity, and the main motor 4 is fixedly connected to the top inner wall of the cylinder body 1 through the support ribs 5. The main motor 4 is vertically arranged and the output shaft at the bottom is fixedly connected to the squirrel cage wind wheel 6, and the squirrel cage wind wheel 6 Located above the air outlet end of the guide plate 3, several fins 7 are fixed verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com