A camera defogging system

A technology of camera and heating module, which is applied in the parts of TV system, camera, image communication, etc., can solve the problems of affecting the shooting effect and cracking of window glass, and achieve the effect of convenient control and good defogging effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

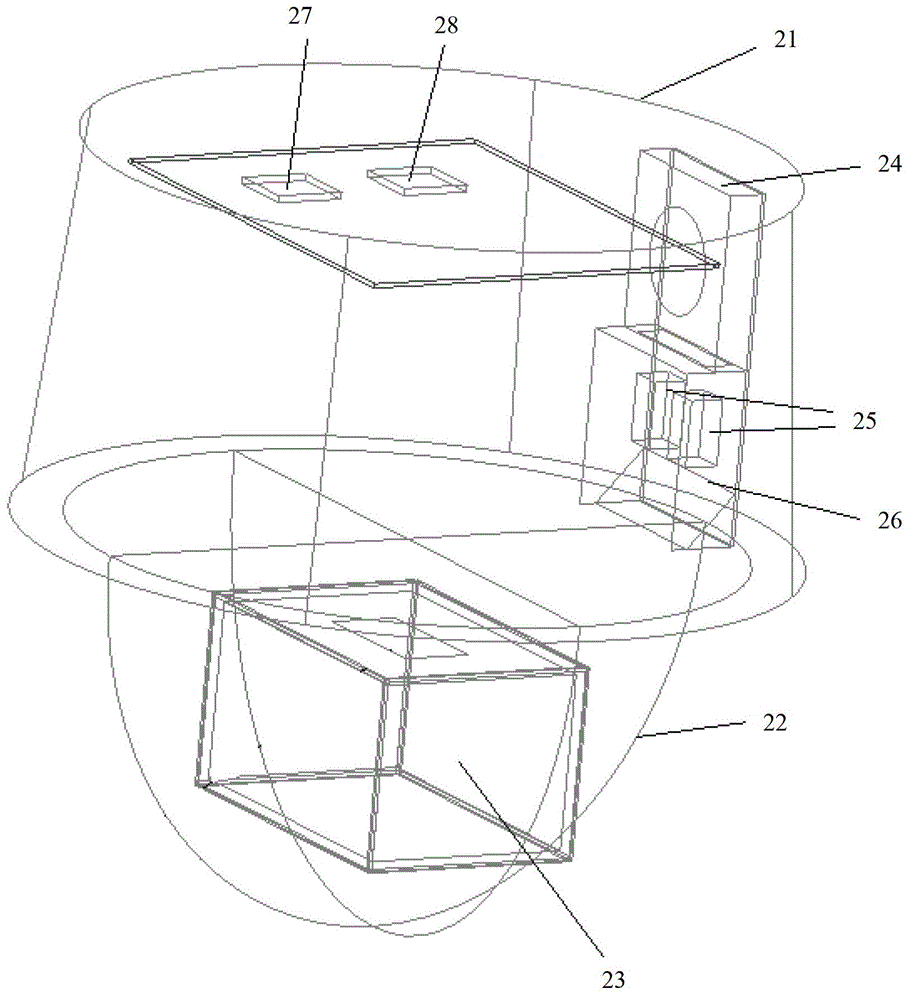

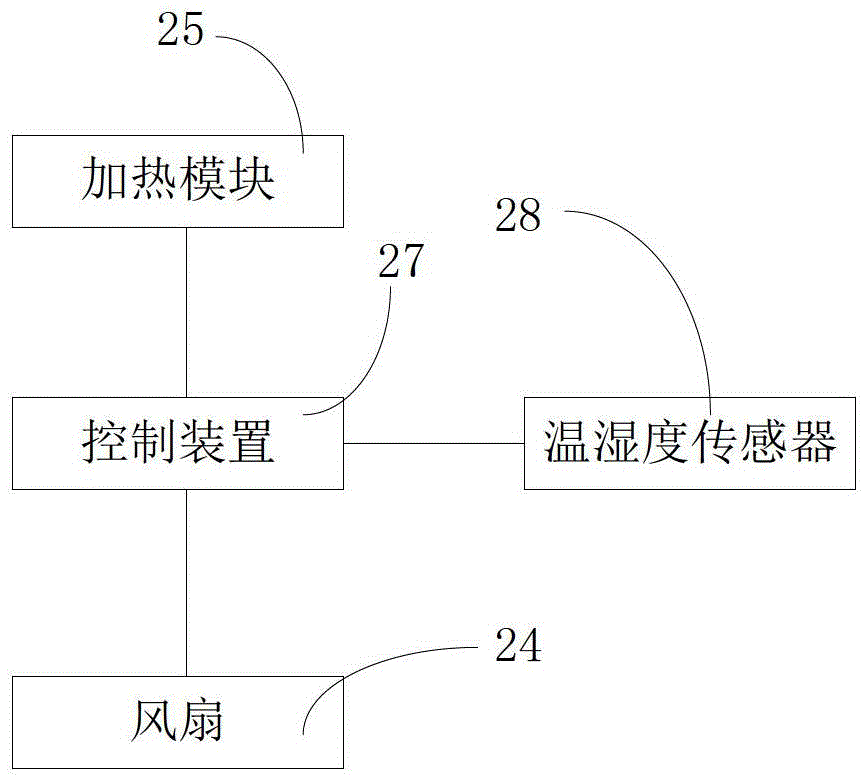

[0014] figure 2 It is a structural schematic diagram of a spherical camera shown in this embodiment. The dome camera includes: a casing 21 , a dome cover 22 , a core 23 , a control device 27 , a temperature and humidity sensor 28 , a heating module 25 and a fan 24 . The dome cover 22 is a transparent cover. When the lens of the movement is shooting an image, if the dome cover is foggy, it will have a great impact on the image clarity. see further image 3 , image 3 It is a control logic diagram of a defogging system. The defogging system includes: a control device 27 , a temperature and humidity sensor 28 , a heating module 25 and a fan 24 . The temperature and humidity sensor senses the temperature and humidity inside the camera. The temperature and humidity sensor here may be an integrated temperature and humidity sensor, or may be a combinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com