Compact wastewater concentrator using waste heat

A concentrator and demister technology, applied in dehydration/drying/concentrated sludge treatment, heating water/sewage treatment, combustion type, etc., can solve problems such as corrosion, expensive exhaust gas, and increase the cost of structural support requirements, to achieve The effect of reasonable manufacturing and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

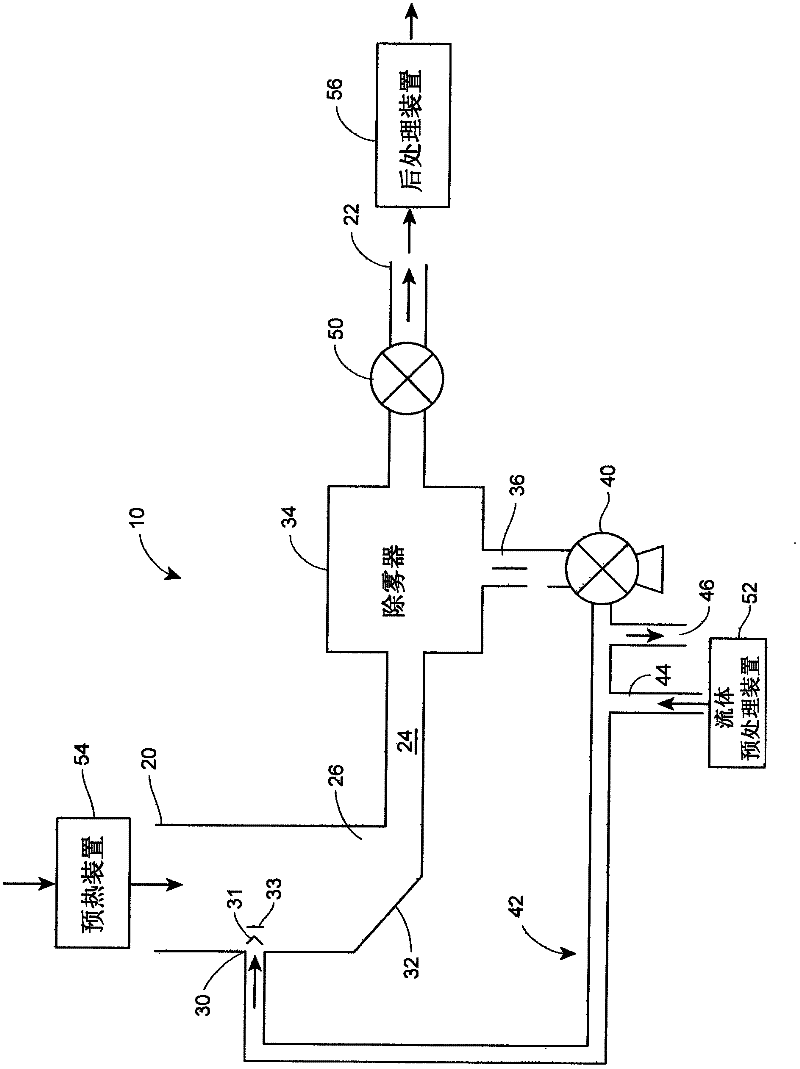

[0028] figure 1 An overall schematic view of the liquid concentrator 10 is shown, comprising a gas inlet 20 , a gas outlet 22 and a flow path 24 connecting the gas inlet 20 to the gas outlet 22 . Flow passage 24 includes a narrow portion 26 that accelerates gas flow through flow passage 24 , thereby creating turbulent flow within or near the narrow portion within flow passage 24 . In this embodiment, the narrow portion 26 is formed by a Venturi device. The liquid inlet 30 injects the liquid to be concentrated (by evaporation) into the liquid concentration chamber in the flow path 24 at a position upstream of the narrow portion 26 , and the injected liquid is combined with the gas flow in the flow path 24 . Liquid inlet 30 may include one or more replaceable nozzles 31 for spraying liquid into flow passage 24 . The liquid inlet 30 , whether equipped with a nozzle 31 or not, can inject liquid in any direction perpendicular or parallel to the gas flow as the gas passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com